Composite shape memory fiber with thermosetting/thermoplastic core-shell structure and preparation method of composite shape memory fiber

A core-shell structure and composite fiber technology, applied in fiber processing, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve the problem of not having the scope of biological applications, and the inability to obtain micro-nano-sized structure applications, etc. problems, to achieve excellent shape memory performance, low cost, and simple spinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

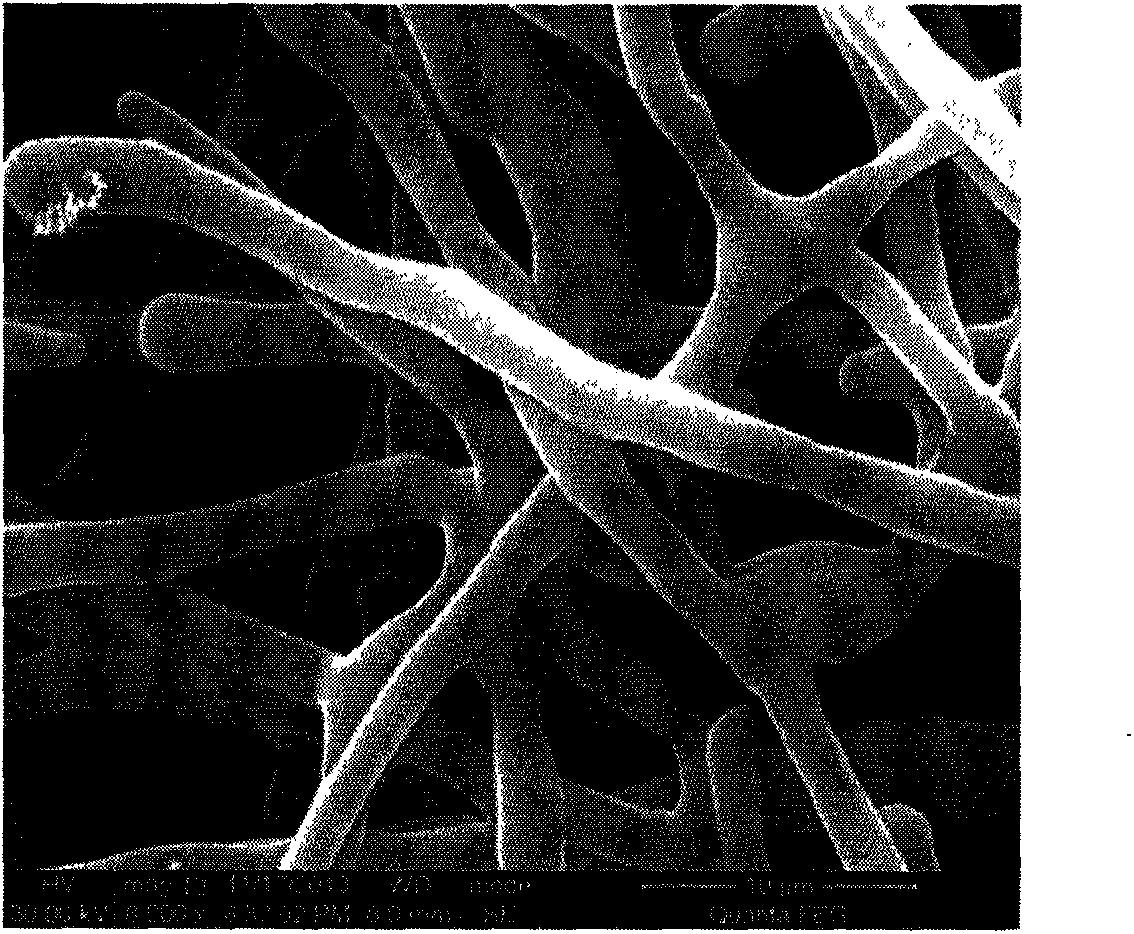

Embodiment 1

[0025] (1) Polycaprolactone (PCL, molecular weight 50000) and benzophenone are dissolved in a mixed solvent of dichloromethane and N,N-dimethylformamide in a volume ratio of 4:1 in a mass ratio of 10:1 In the method, a solution having a polycaprolactone concentration of 15wt% was prepared, and stirred at room temperature until the two substances were mixed and dispersed evenly to obtain a uniform electrospinning solution;

[0026] (2) Mix the epoxy resin (E51) and the curing accelerator triethanolamine according to the mass ratio of 80:30, stir at room temperature until uniform, and use it as the core layer spinning solution;

[0027] (3) the polycaprolactone solution that above-mentioned step (1) is made is as shell layer spinning liquid, and the epoxy resin solution that step (2) makes is as nuclear layer spinning liquid, injects respectively into the coaxial spinning needle The shell and the core are coaxially electrospun under ultraviolet light. The spinning parameters are...

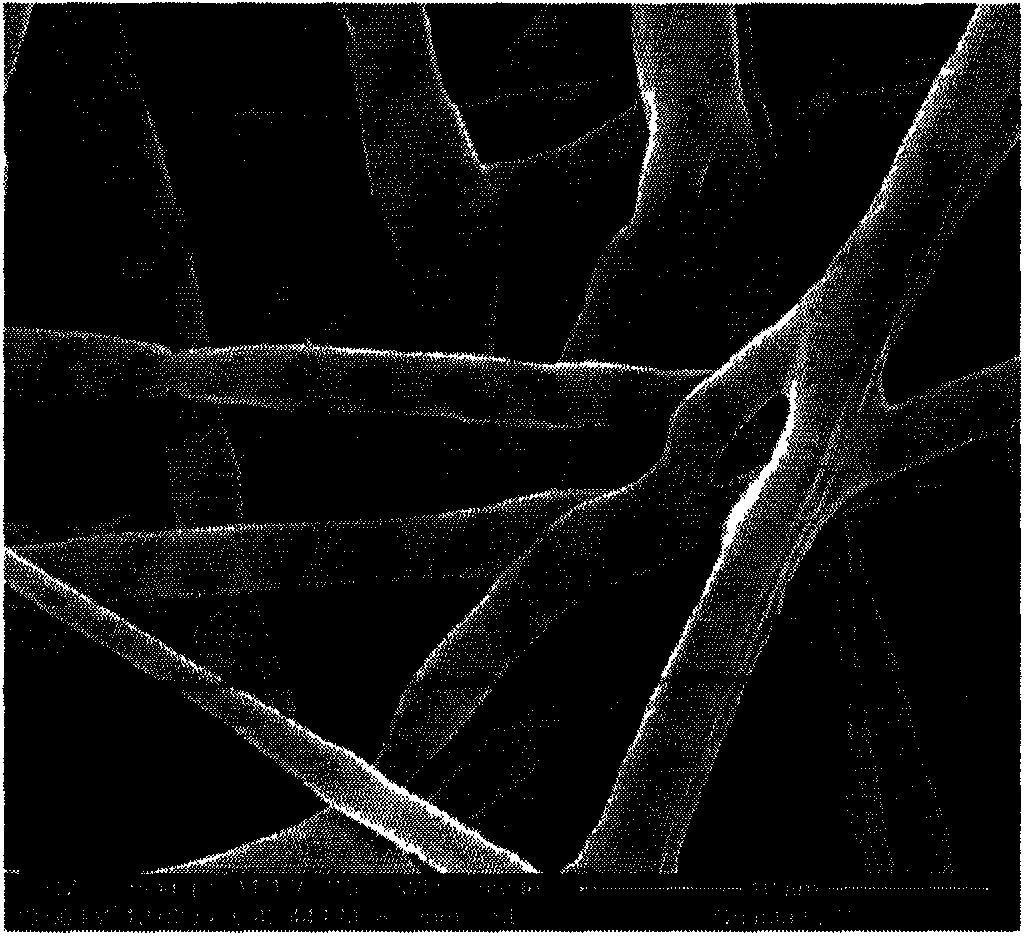

Embodiment 2

[0030] (1) Polycaprolactone (PCL, molecular weight 50000) and benzophenone are dissolved in a mixed solvent of dichloromethane and N,N-dimethylformamide in a volume ratio of 4:1 in a mass ratio of 10:1 In the solution, the concentration is prepared into a solution of 15wt%, stirred at room temperature until the two substances are mixed and dispersed evenly, and a uniform electrospinning solution is obtained;

[0031] (2) Mix epoxy resin (E51) and curing accelerator triethanolamine according to a mass ratio of 80:30, and stir at room temperature until uniform;

[0032] (3) the polycaprolactone solution that above-mentioned step (1) is made is as shell layer spinning liquid, and the epoxy resin solution that step (2) makes is as nuclear layer spinning liquid, injects respectively into the coaxial spinning needle The shell and the core are coaxially electrospun under ultraviolet light. The spinning parameters are: the inner diameter of the shell is 1 mm, the inner diameter of the...

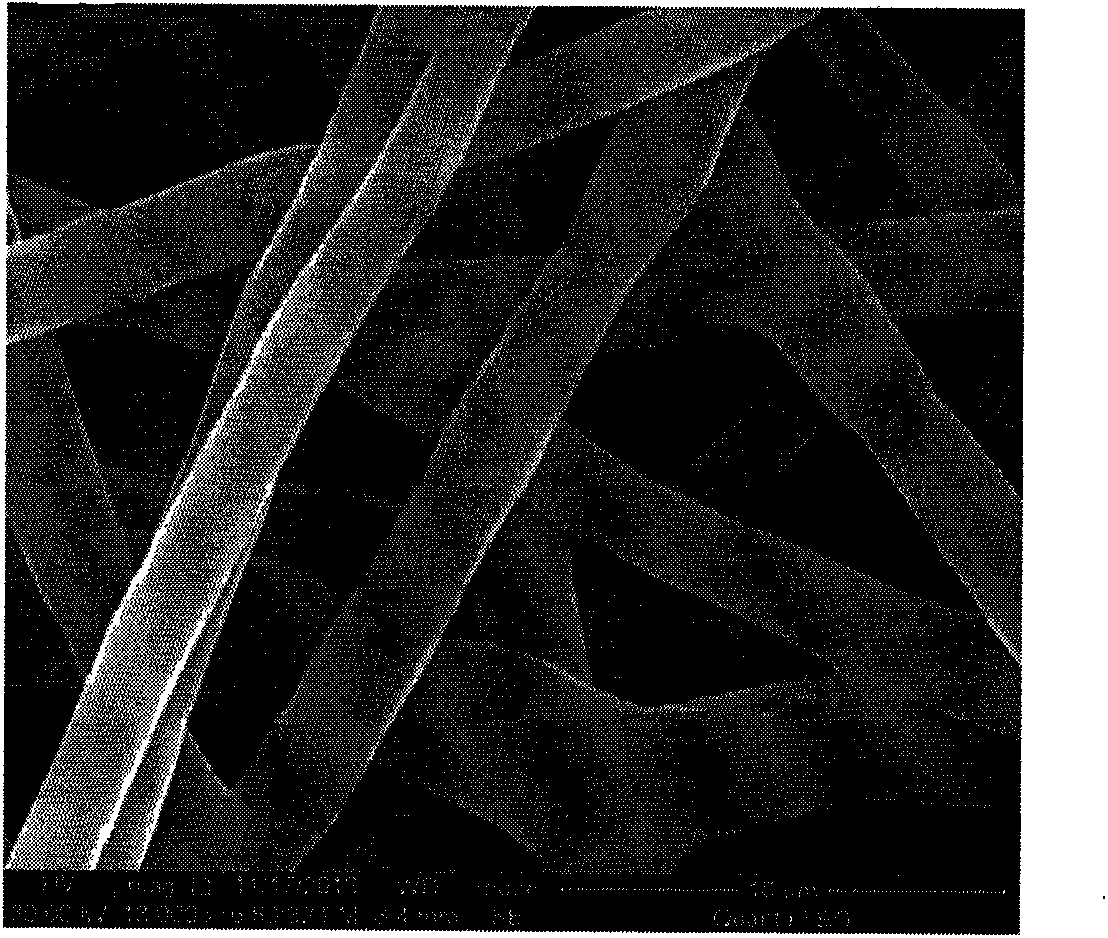

Embodiment 3

[0036] (1) Polycaprolactone (PCL, molecular weight 50000) and benzophenone are dissolved in a mixed solvent of dichloromethane and N,N-dimethylformamide in a volume ratio of 4:1 in a mass ratio of 10:1 In the solution, the concentration is prepared into a solution of 15wt%, stirred at room temperature until the two substances are mixed and dispersed evenly, and a uniform electrospinning solution is obtained;

[0037] (2) Mix epoxy resin (E51) and curing accelerator triethanolamine according to a mass ratio of 80:30, and stir at room temperature until uniform;

[0038](3) the polycaprolactone solution that above-mentioned step (1) is made is as shell layer spinning liquid, and the epoxy resin solution that step (2) makes is as nuclear layer spinning liquid, injects respectively into the coaxial spinning needle The shell and the core are coaxially electrospun under ultraviolet light. The spinning parameters are: the inner diameter of the shell is 1 mm, the inner diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com