Dust collecting bag

A bag, modified technology, applied in the separation of dispersed particles, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of reducing the filtration efficiency of dust collectors, increasing the energy consumption of dust collectors, affecting equipment efficiency, etc., and reducing replacement. and cleaning frequency, the effect of light weight, non-absorbent surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

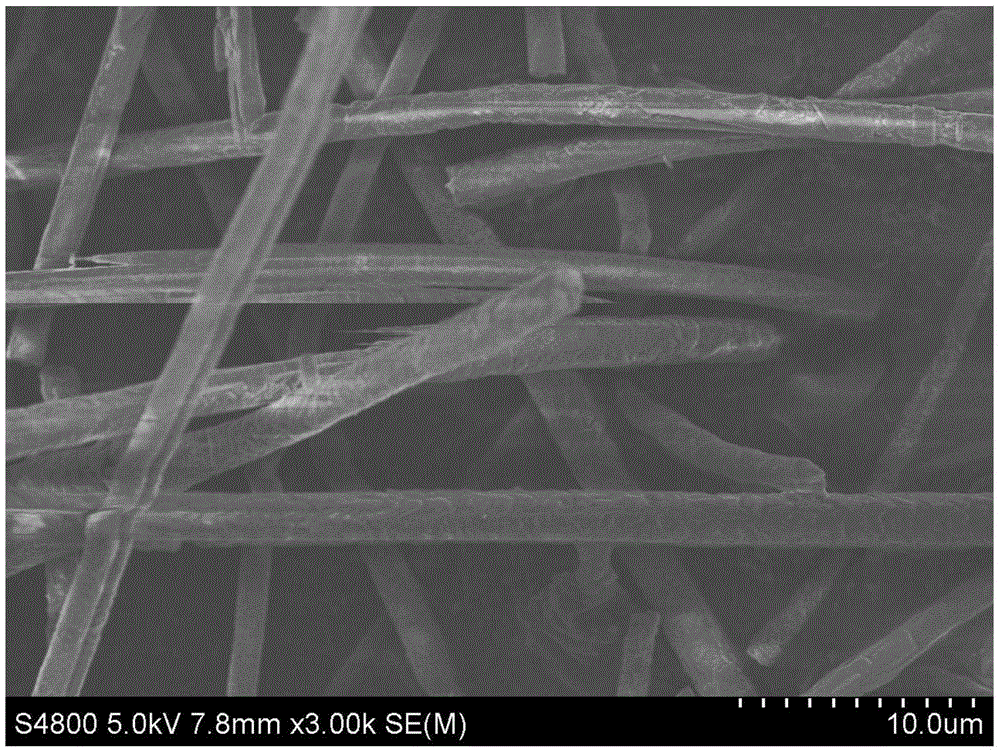

Image

Examples

Embodiment 1

[0018] Weighing: Weigh 1kg of graphene (the surface contains -NO 2 group), 99kg of polyamide, was added to ethanol to fully disperse, and then 0.1kg of polyvinylpyrrolidone was added to adjust the viscosity of the spinning solution.

[0019] Preparation: The spinning solution was prepared into fibers by electrospinning, wherein the spinning voltage was controlled at 7KV, the receiving distance was 5cm, and the spinning speed was 0.01ml / min. Finally, the fibers prepared above are further processed into dust-removing cloth bags.

Embodiment 2

[0021] Weighing: Weigh 5kg graphene (the surface contains -NO 2 Group), 95kg polyamide, join in ethanol and fully disperse, then add 1.5kg polyvinylpyrrolidone, adjust the viscosity of spinning solution.

[0022] Preparation: The spinning solution was prepared into fibers by electrospinning, wherein the spinning voltage was controlled to be 10KV, the receiving distance was 20cm, and the spinning speed was 0.5ml / min. Finally, the fibers prepared above are further processed into dust-removing cloth bags.

Embodiment 3

[0024] Weighing: Weigh 5kg graphene (the surface contains -NO 2 Group), 95kg polyamide, join in NMP and fully disperse, then add 1.5kg polyvinylpyrrolidone, adjust the viscosity of spinning solution.

[0025] Preparation: The spinning solution was prepared into fibers by electrospinning, wherein the spinning voltage was controlled to be 10KV, the receiving distance was 20cm, and the spinning speed was 0.5ml / min. Finally, the fibers prepared above are further processed into dust-removing cloth bags.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com