Method for extracting methane from oxygen-containing coal-bed gas through low-temperature liquefying separation

A technology for liquefaction and separation of coalbed methane, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve problems such as insufficient technical maturity, poor technical economy, and high cost of deep deoxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

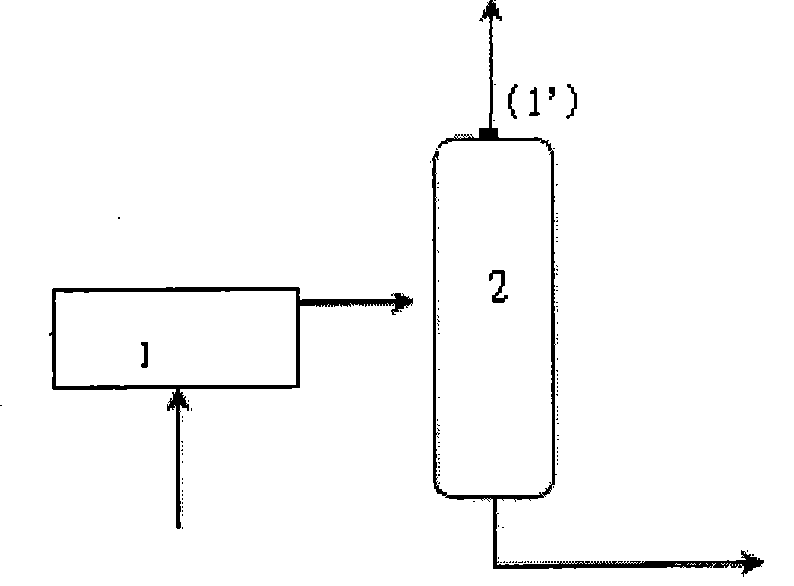

[0068] An oxygen-containing coalbed methane mixture, the oxygen-containing coalbed gas first enters the refrigeration system of the device 1 to cool down, then enters the rectification tower 2 to be separated into tail gas and liquid pure methane, and flows out from the tail gas outlet point 1' at the top of the rectification tower Tail gas, liquid pure methane flows out from the bottom of the rectification tower.

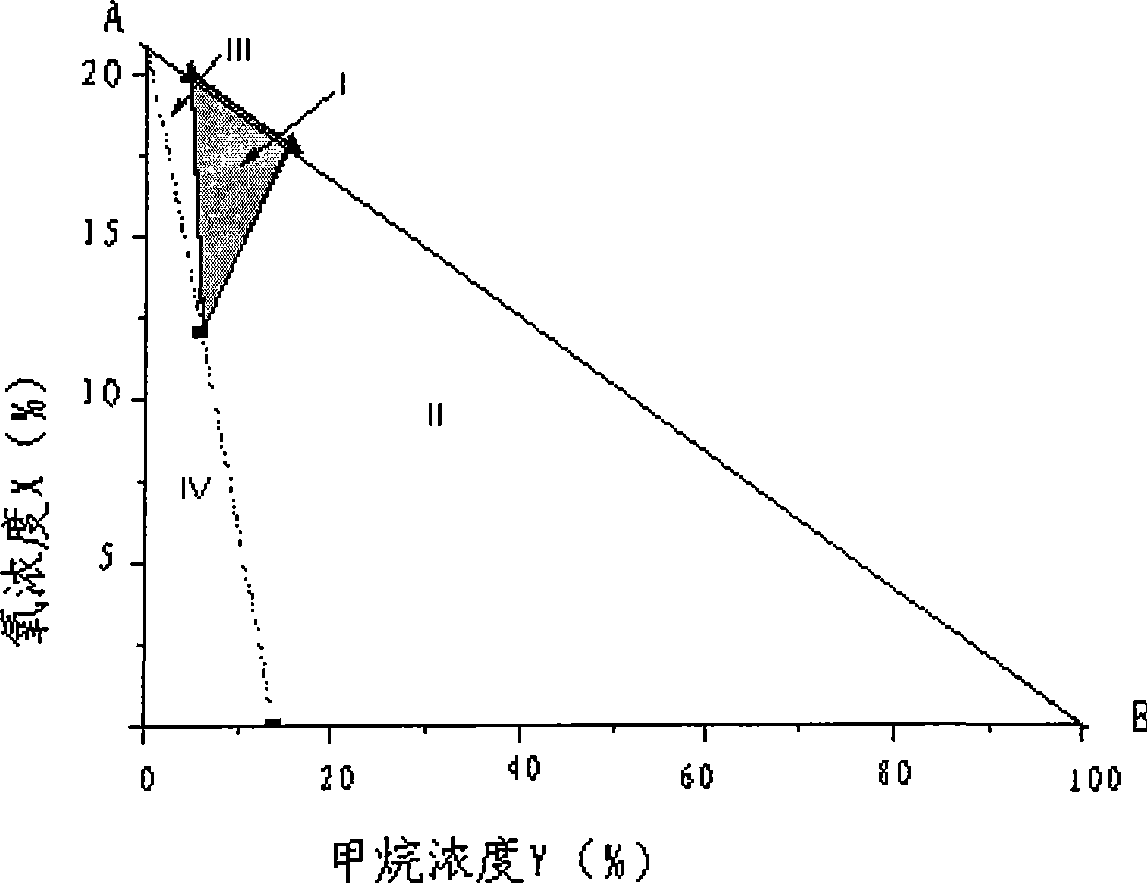

[0069] First determine the most explosive position in the separation system. Since the separation system has no cooling capacity recovery, the separation system sees figure 2 . For the separation system without cooling recovery, the temperature of oxygen-containing coalbed methane in the rectification tower decreases gradually, the content of methane gradually decreases, and the content of oxygen gradually increases, and the temperature at the tail gas outlet at the top of the rectification tower is the lowest, here The content of methane reaches the lowest and t...

Embodiment 2

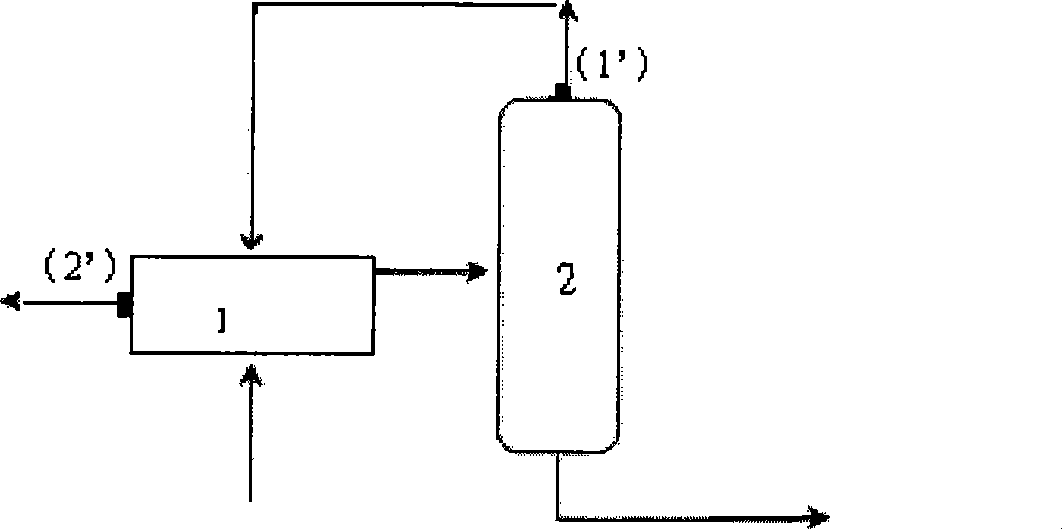

[0075] A mixture of oxygen-containing coalbed methane. The oxygen-containing coalbed methane first enters the refrigeration system of the device 1 to cool down, and then enters the rectification tower 2 to be separated into tail gas and liquid pure methane. The liquid pure methane flows out from the bottom of the rectification tower, and the tail gas Enter the cold recovery system of the device 1 to recover the cold, and then flow out from the outlet 2' of the cold recovery system. The refrigeration system and the cold recovery system in this embodiment are both in the device 1.

[0076] First determine the most explosive position in the separation system, since the separation system has cold recovery, the separation system sees image 3 , for the separation system with cooling recovery, there is no explosion at the tail gas outlet at the top of the rectification tower, and the temperature and pressure of the oxygen-containing coalbed gas at the position between the cooling rec...

Embodiment 3

[0083] An oxygen-containing mixture of coalbed methane. The oxygen-containing coalbed methane first enters the refrigeration system in the device 1 to cool down, and then enters the rectification system 2 to be separated into tail gas and liquid pure methane. The liquid pure methane flows out from the bottom of the rectification system, and the tail gas Outflow from the top 1' of the rectification system 2.

[0084] Since the separation system has no cooling recovery, the most prone to explosion is at the tail gas outlet point 1' at the top of the rectification system 2, and the initial state of this position is temperature -50°C and pressure 0.3MPa. Refer to Example 1 for the establishment method of the coordinate region of the oxygen-containing coalbed methane in the separation process and the explosion triangle at the position where the explosion is most likely to occur, wherein the initial concentrations of methane, oxygen and nitrogen are 8%, 5% and 87% respectively , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com