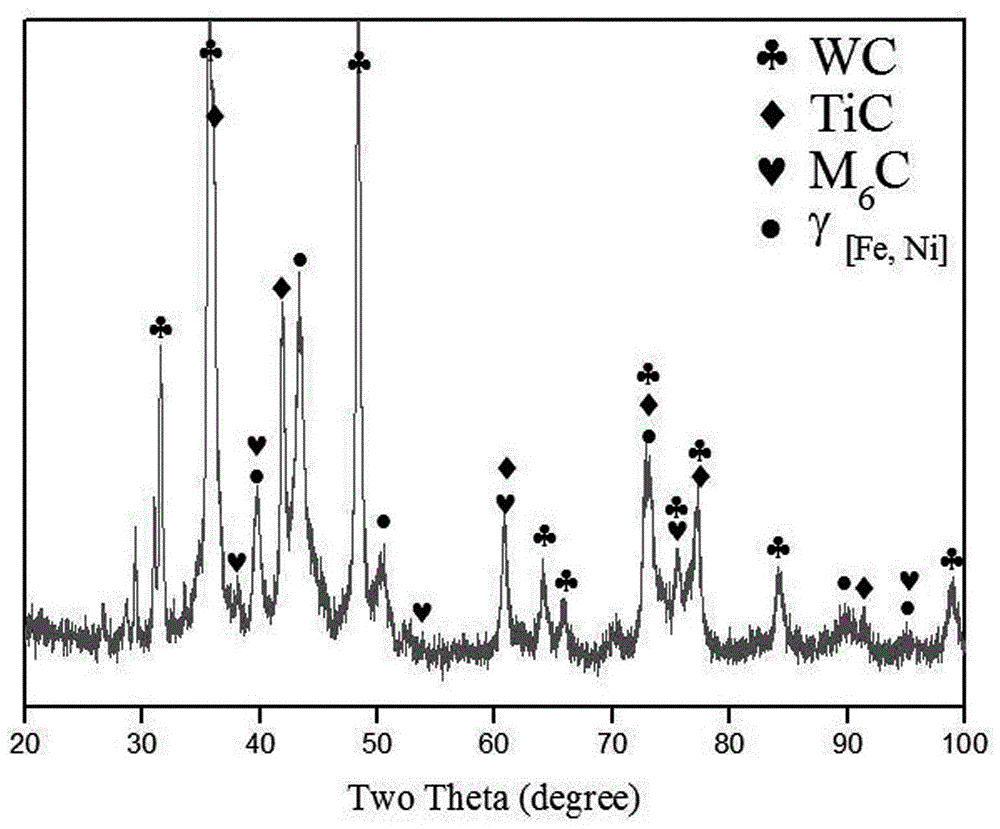

Preparation method of in-situ self-generated wc+tic composite reinforced iron-based wear-resistant coating

A composite reinforcement and wear-resistant coating technology, which is applied in the field of wear-resistant coatings, can solve problems such as the mismatch between the hardness of the reinforcement phase and the matrix, and achieve the effects of strong adaptability to shape and size, simple equipment, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0024] Carry out mechanical processing on the substrate to make suitable tools or molds, and clean the grease on the surface with acetone; if it is to remanufacture the failed parts, it is necessary to sandblast or polish the surface with a hand-held grinding wheel, and clean the grease on the surface with acetone Grease; put the pre-treated substrate into the workpiece table, and clamp and fix it.

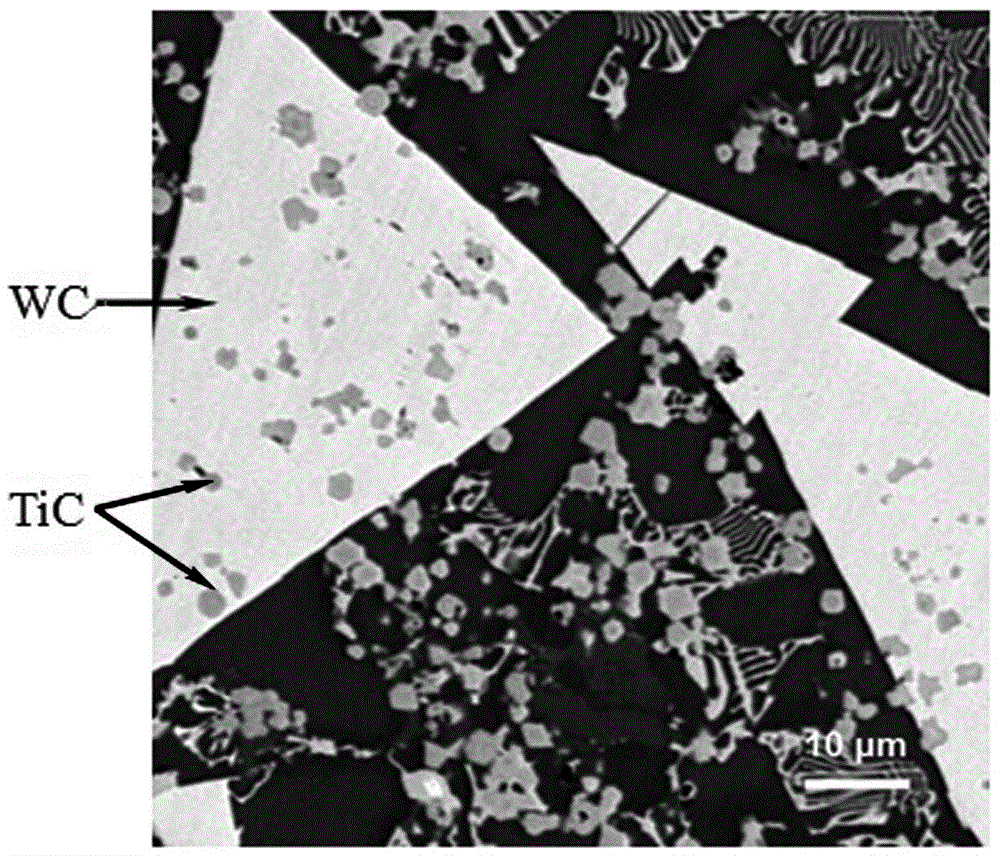

[0025] The preparation of the in-situ synthesized TiC+WC composite reinforced coating on the surface of the substrate is completed through three examples below.

Embodiment 1

[0027] According to mass percentage, 38% W powder (W≥99.8%, particle size 40~80μm), 0.2% Ti powder (Ti≥99.0; Fe≤0.25%; Si≤0.1%; O≤0.65%, particle size 40~ 80μm), 3.18% C powder (C≥98%, particle size 20~40μm), the balance is Fe-Ni self-fluxing alloy powder (Ni=30%; Re=1%; Fe=69%, particle size is 60 ~180μm) after drying, stir evenly, pre-load it into a high-temperature resistant ceramic sleeve bonded to the surface of low-carbon steel Q235, and heat it with a plasma beam. The process is: non-arc (non-transferred plasma arc), current 25-45A , Voltage 40-55V, heating time 4-6 seconds; arc transfer (transferred plasma arc), current 30-50A, voltage 40-60V, heating time 6-8 seconds, the coating is naturally cooled to room temperature in the air.

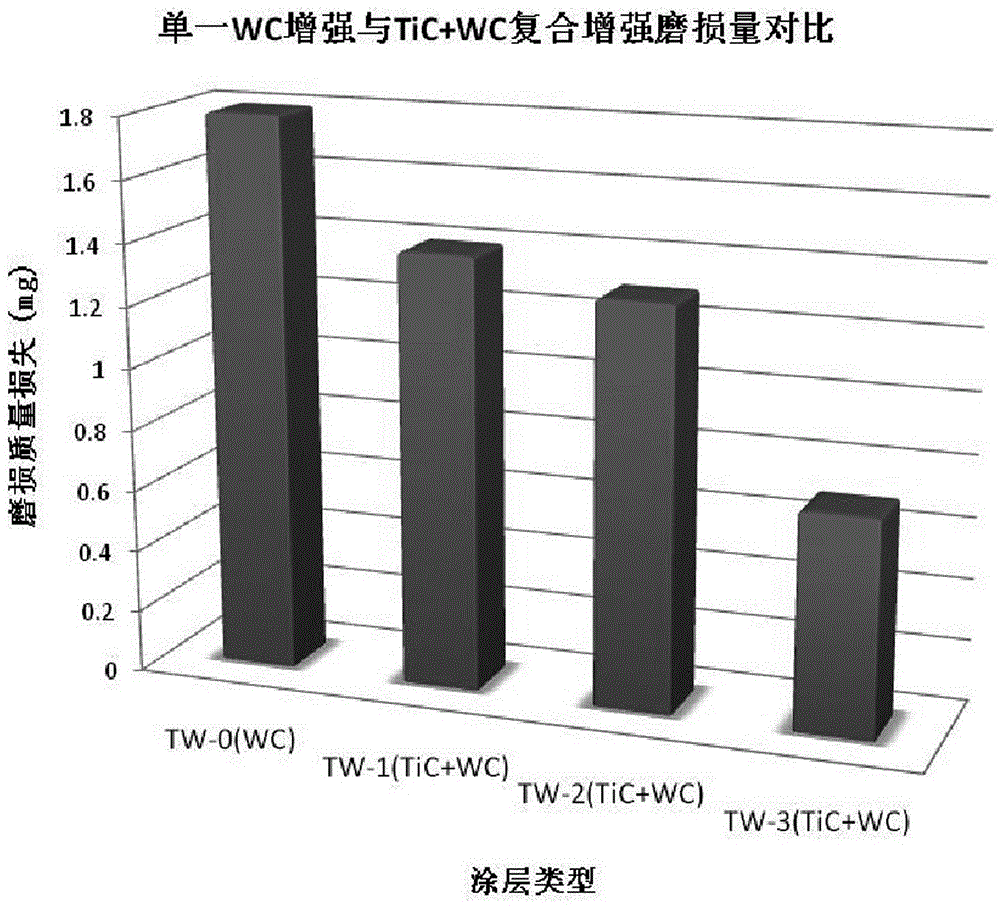

[0028] The obtained TiC+WC composite reinforced iron-based coating was subjected to a grinding test (pressure 300N, sliding 500 meters) with a T10 grinding sample (Rockwell hardness HRC=63±1) on an M-2000 wear testing machine. Compared wi...

Embodiment 2

[0030] According to mass percentage, 38% W powder (W≥99.8%, particle size 40~80μm), 0.3% Ti powder (Ti≥99.0; Fe≤0.25%; Si≤0.1%; O≤0.65%, particle size 40~ 80μm), 3.18% C powder (C≥98%, particle size 20~40μm), the balance is Fe-Ni self-fluxing alloy powder (Ni=30%; Re=1%; Fe=69%, particle size is 60 ~180μm) after drying, stir evenly, pre-load it into a high-temperature resistant ceramic sleeve bonded to the surface of low-carbon steel Q235, and heat it with a plasma beam. The process is: non-arc (non-transferred plasma arc), current 25-45A , Voltage 40-55V, heating time 4-6 seconds; arc transfer (transferred plasma arc), current 30-50A, voltage 40-60V, heating time 6-8 seconds, the coating is naturally cooled to room temperature in the air.

[0031] The obtained TiC+WC composite reinforced iron-based coating was subjected to a grinding test (pressure 300N, sliding 500 meters) with a T10 grinding sample (Rockwell hardness HRC=63±1) on an M-2000 wear testing machine. Compared wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com