Active-carbon and regenerated-cellulose composite material and preparing method thereof

A technology of regenerated cellulose and composite materials, which is applied in the field of activated carbon and regenerated cellulose composite materials and their preparation, can solve problems such as limited use of activated carbon, and achieve the effects of simple activated carbon pretreatment process, shortened process flow, and good adsorption characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

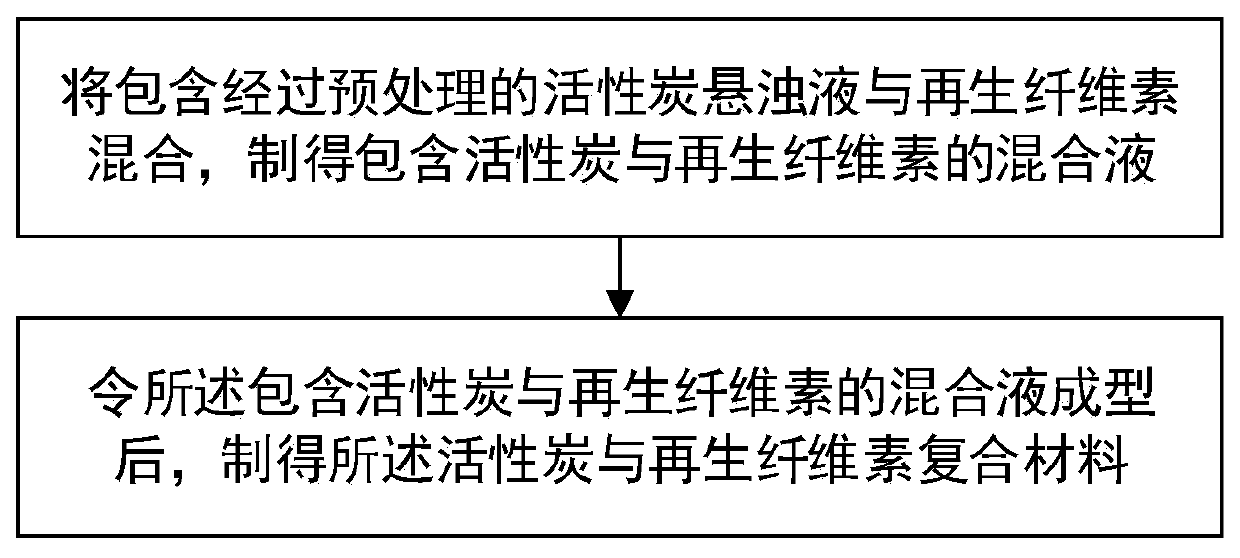

Method used

Image

Examples

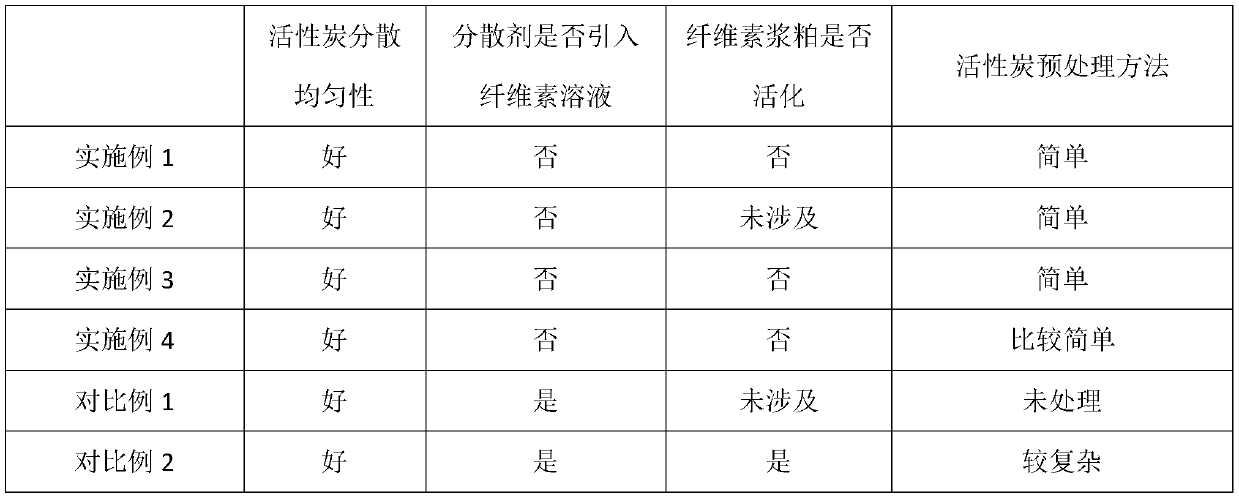

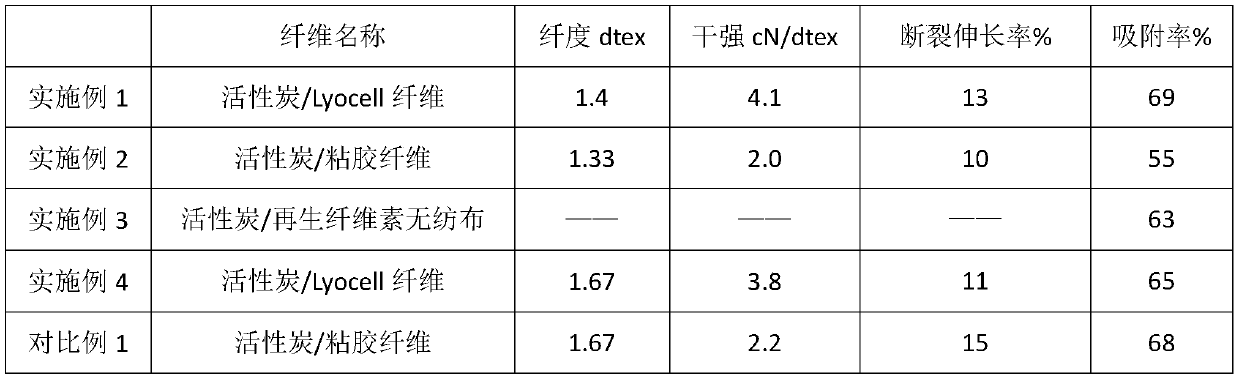

Embodiment 1

[0037] A preparation method of activated carbon and regenerated cellulose composite material, the steps are as follows:

[0038] (1) The pretreatment method of activated carbon, activated carbon is added to H 2 o 2 , reflux reaction for 4 hours, then washed with deionized water and then dried to obtain pretreated activated carbon with a water content of 20% by mass;

[0039] (2) The pretreated activated carbon prepared in step (1) and the aqueous solution of N-methylmorpholine-N-oxide (NMMO) with a mass percent content of 74% are stirred and dispersed at 80°C to prepare A mixed suspension consisting of activated carbon, NMMO and water;

[0040] (3) mixing the mixed suspension prepared in step (2) with the cellulose pulp at 85° C. to make a cellulose mixed solution;

[0041] (4) The temperature of the cellulose mixture prepared in step (3) was gradually raised to 108° C., and activated carbon and regenerated cellulose solution were obtained through evaporation and dehydratio...

Embodiment 2

[0044] A preparation method of activated carbon and regenerated cellulose composite material, the steps are as follows:

[0045] (1) The pretreatment method of activated carbon, the untreated activated carbon is added to H 2 o 2 , reflux reaction for 3 hours, and then dry to obtain activated carbon with a moisture content of 5% by mass;

[0046] (2) The activated carbon prepared in step (1) is mixed with the viscose spinning solution, stirred and mixed for 2 hours to obtain the mixed spinning solution of activated carbon and viscose, which is filtered, defoamed, filtered, and finally wet-spun Shaping technology produces viscose fibers containing activated carbon.

Embodiment 3

[0048] A preparation method of activated carbon and regenerated cellulose composite material, the steps are as follows:

[0049] (1) The pretreatment method of activated carbon, the untreated activated carbon is added to H 2 o 2 , reflux reaction for 2 hours, then washed with deionized water and then dried to obtain activated carbon with a water content of 10% by mass;

[0050] (2) Stir and disperse the activated carbon prepared in step (1) and the NMMO aqueous solution with a mass percentage of 73% at 80° C. to prepare a mixture suspension comprising activated carbon, NMMO and water;

[0051] (3) mixing the mixed suspension prepared in step (2) with the cellulose pulp at 90°C to make a cellulose mixed solution;

[0052] (4) The cellulose mixed solution prepared in step (3) is gradually warmed up to 105° C., and activated carbon and regenerated cellulose solution are obtained through evaporation and dehydration during the heating process;

[0053] (5) Filtrating the activated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com