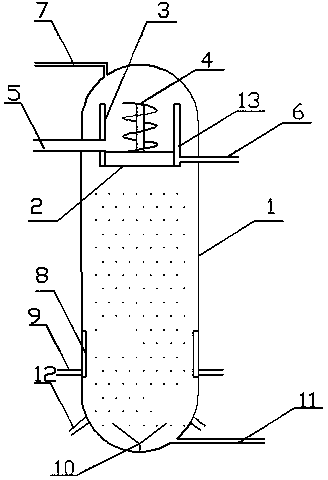

Method for producing xylitol by using eucalypt chip hydrolysis fluid and hydrolyzing tower

A technology of hydrolyzate and eucalyptus wood chips, which is applied in the field of hydrolysis towers, can solve the problems of low utilization value of waste residue, waste of resources and energy, and low production efficiency, and achieve the effects of improving raw material utilization, saving time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Pump the aqueous solution of eucalyptus chips into the continuous hydrolysis tower. The hydrolysis reaction time of eucalyptus chips is 2.5h, the reaction temperature is 165°C, the pressure is 0.7MPa, and the mass ratio of eucalyptus chips to water is 1:4. After continuous extraction, the conversion rate of pentose sugars reached 60.8%;

[0036] The eucalyptus chip hydrolyzate was hydrolyzed for 90 minutes under the conditions of sulfuric acid concentration 10g / l and temperature 120°C, the dry matter concentration was 5%, the inorganic acid content was 1.2%, and the xylose purity was 65%;

[0037] The hydrolyzate was decolorized for 40 minutes at a temperature of 75°C. The amount of activated carbon added was 7% of the dry matter. The decolorized solution was ion-exchanged according to the anion-yang process to obtain a primary ion-exchange solution. Light shading: 5%, light transmission 86.5%, Total acid: 0.4%;

[0038] Concentrate the primary ion exchange liquid to a...

Embodiment 2

[0048] Pump the aqueous solution of eucalyptus chips into the continuous hydrolysis tower. The hydrolysis reaction time of eucalyptus chips is 3h, the reaction temperature is 170°C, the pressure is 0.76MPa, and the mass ratio of eucalyptus chips to water is 1:4. After continuous extraction, the conversion rate of pentose sugars reached 63.3%;

[0049] The eucalyptus chip hydrolyzate was hydrolyzed for 120 minutes at a sulfuric acid concentration of 7g / l and a temperature of 120°C. The dry matter concentration was 8%, the inorganic acid content was 0.8%, and the xylose purity was 67.5%.

[0050]The hydrolyzate was decolorized for 45 minutes at a temperature of 80°C. The amount of activated carbon added was 10% of the dry matter. The decolorized solution was ion-exchanged according to the anion-yang process to obtain a primary ion-exchange liquid with 8% shading and 89% light transmission. , total acid: 0.3%;

[0051] Concentrate the primary ion exchange solution to a xylose co...

Embodiment 3

[0054] Pump the aqueous solution of wood chips into the continuous hydrolysis tower. The reaction time of wood chips hydrolysis is 4 hours, the reaction temperature is 170°C, the pressure is 0.76%, the mass ratio of wood chips to water is 1:4, and the hydrolyzate is continuously extracted in the lower part of the reaction tower. out, the pentose conversion rate reached 64.3%;

[0055] The eucalyptus hydrolyzate was hydrolyzed for 120 minutes at a sulfuric acid concentration of 8g / l and a temperature of 120°C. The dry matter concentration was 12%, the inorganic acid content was 1.0%, and the xylose purity was 69%.

[0056] The hydrolyzate was decolorized for 45 minutes at a temperature of 70°C. The amount of activated carbon added was 10% of the dry matter. The decolorized solution was ion-exchanged according to the anion-yang process to obtain a primary ion exchange liquid. , total acid: 0.4%;

[0057] Concentrate the primary ion exchange liquid to a xylose content of 55%, fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com