Method for achieving in-situ synthesis of aluminum oxide enhanced ferrum-based powder metallurgy alloy

An iron-based powder metallurgy and in-situ synthesis technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor wettability, poor bonding, insoluble in metal matrix, etc., achieve high interface bonding strength and improve production efficiency , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

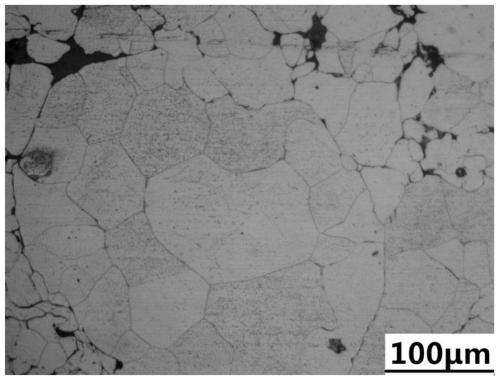

Embodiment 1

[0024] First take 60g of iron powder (purity of 99.5%, particle size of 300 mesh), put it in a muffle furnace, oxidize it at a temperature of 100 ° C for 1 hour, and then add 1% of the total mass of zinc stearate and zinc stearate to the iron powder. The total mass of 1% aluminum powder (purity of 99.5%, particle size of 400 mesh) was ball-milled in a QM-3SP2 planetary ball mill, with a ball-to-material ratio of 10:1, mixed at a speed of 300r / min for 2 hours, and then used The metal powder (about 6g) was pressed into a cylinder with a diameter of 20mm under a pressure of 450Mpa, and the pressure holding time was 6min. Finally, the pressed pattern was placed in a vacuum sintering furnace for sintering. The sintering temperature was 1100°C and the holding time was 1h.

Embodiment 2

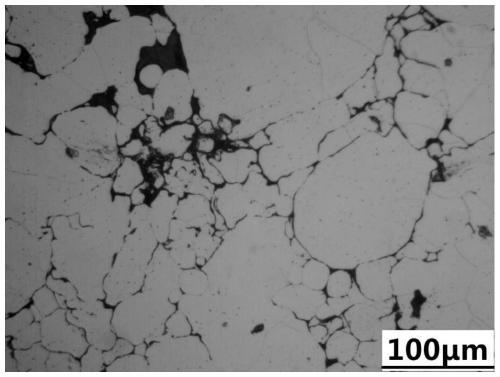

[0026] The difference between this example and Example 1 is that the oxidation time is 0.5h, and the content of the added aluminum powder is 5% of the total mass.

Embodiment 3

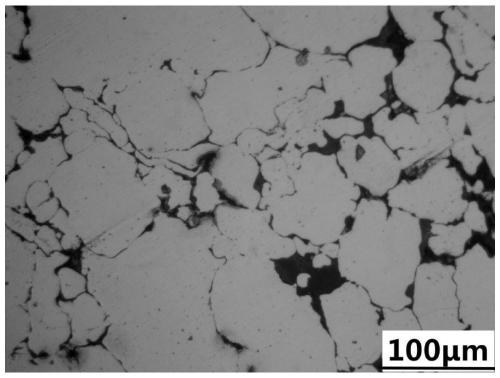

[0028] The difference between this example and Example 1 is that the content of the added aluminum powder is 10% of the total mass, and the rotational speed of the ball mill is 400 r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com