Battery pack, vehicle and energy storage device

A battery pack and battery placement technology, applied in vehicle energy storage, electric power devices, battery/fuel cell control devices, etc., can solve problems such as adverse effects on battery pack quality, reduced reliability, increased manpower, material resources and other costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

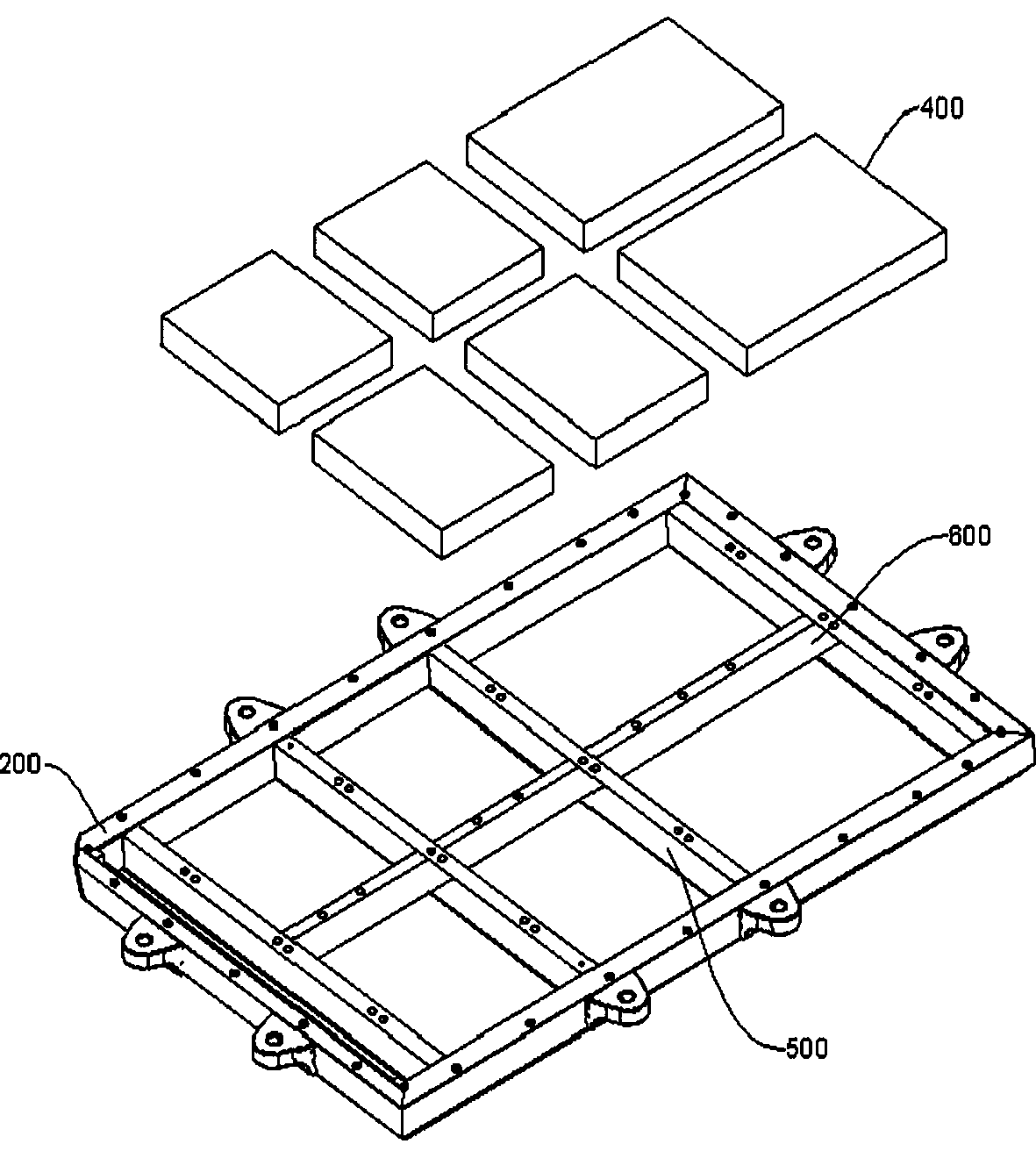

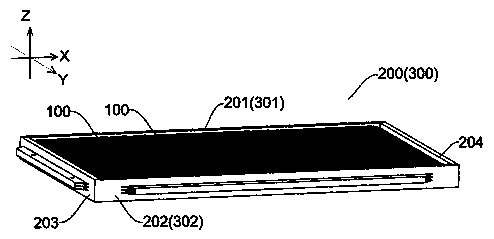

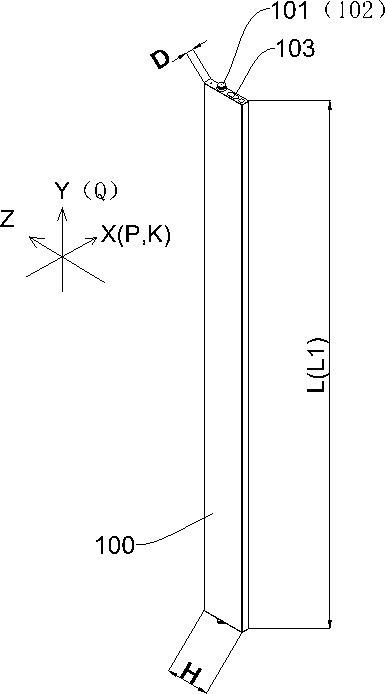

[0303] According to the battery pack 200 of the embodiment of the present application, such as Figure 21As shown, the length direction of the single battery 100 is arranged along the width direction of the battery pack 200, a plurality of single cells 100 are arranged along the length direction of the battery pack 200, and in the width direction of the battery pack 200, the battery pack housing accommodates a single The battery 100 , the single battery 100 extends from one side of the battery pack case to the other side in the width direction of the battery pack 200 . A first separator 700 is arranged inside the battery pack casing, and the second separator 800 is not provided. The first separator 700 extends along the width direction of the battery pack 200 , and a plurality of single cells 100 are arranged along the length direction of the battery pack 200 to form For the battery array 400 , the first separator 700 divides the battery array 400 into two parts along the leng...

Embodiment 2

[0305] According to the battery pack 200 of the embodiment of the present application, such as Figure 23 As shown, the length direction of the single battery 100 is arranged along the width direction of the battery pack 200, a plurality of single cells 100 are arranged along the length direction of the battery pack 200, and in the width direction of the battery pack 200, the battery pack housing accommodates a single The battery 100 , the single battery 100 extends from one side of the battery pack case to the other side in the width direction of the battery pack 200 . The first separator 700 and the second separator 800 are not provided in the battery pack casing. The first side beams 201 and the second side beams 202 of the battery pack casing located on both sides of the battery pack 200 in the width direction provide support for the single battery 100 , and the third side beams 203 of the battery pack casing located at both ends of the battery pack 200 in the length direc...

Embodiment 3

[0311] According to the battery pack 200 of the embodiment of the present application, such as Figure 20 As shown, the length direction of the single cells 100 is arranged along the length direction of the battery pack 200, a plurality of single cells 100 are arranged along the width direction of the battery pack 200, and in the length direction of the battery pack 200, the battery pack housing accommodates a single The battery 100 , the single battery 100 extends from one side of the battery pack case to the other side in the length direction of the battery pack 200 . A second separator 800 is arranged inside the battery pack housing without the beam 500. The second separator 800 extends along the length direction of the battery pack 200, and a plurality of single cells 100 are arranged along the width direction of the battery pack 200 to form a battery array 400. , the second separator 800 divides the battery array 400 into two parts along the width direction of the battery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com