Automatic polishing and grinding equipment for inner hole of metal pipe

A technology of polishing and grinding metal tubes, which is applied in metal processing equipment, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of easy explosion, low production efficiency, and polluting the workshop environment, and achieve environmental protection , Improve production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

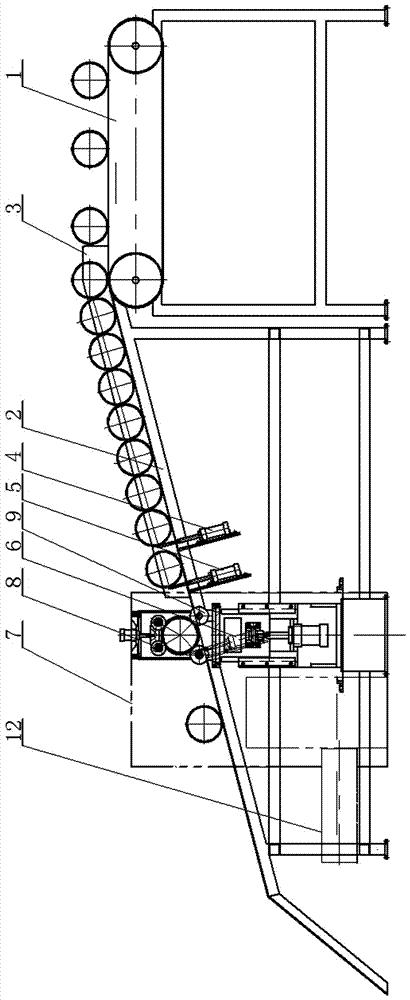

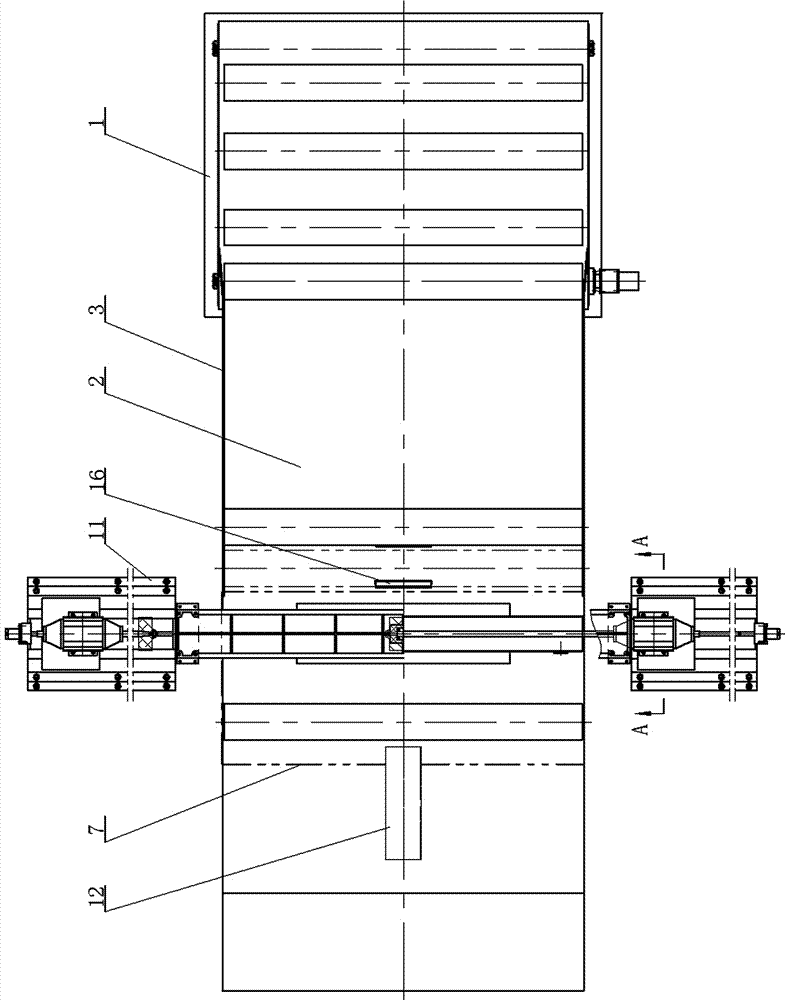

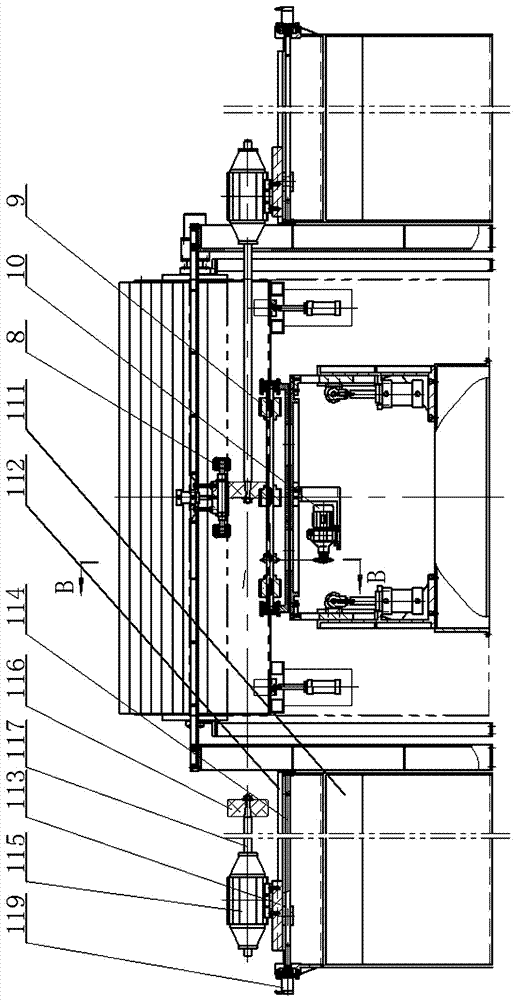

[0018] Depend on Figure 1 to Figure 6 As shown, the metal pipe inner hole automatic polishing and grinding equipment includes a belt conveyor 1 and an inclined slide table 2, side plates 3 are provided on both sides of the inclined slide table 2, and the inclined slide table 2 is located on the side of the belt conveyor 1 At the output end, the lower end of the upper side plate 3 of the inclined slide table 2 is successively equipped with a first material stopper 4, a second material stopper 5, a third material stopper 6 and a dustproof housing 7, and a third material stopper 6 Located in the dust-proof housing 7, a pressure roller device 8 and a supporting roller device 9 are respectively provided above and below the inclined slide table 2 at the third stopper device 6, and the pressure roller device 8 includes a pressurized cylinder 81 and a pressure roller 82. The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com