Method for treating high-titanium desulfurized furnace cinder

A treatment method and blast furnace slag technology, which is applied in the field of high titanium desulfurization blast furnace slag treatment, can solve the problems of hidden safety hazards, explosions, unseen problems, etc., and achieve the effect of safe operation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

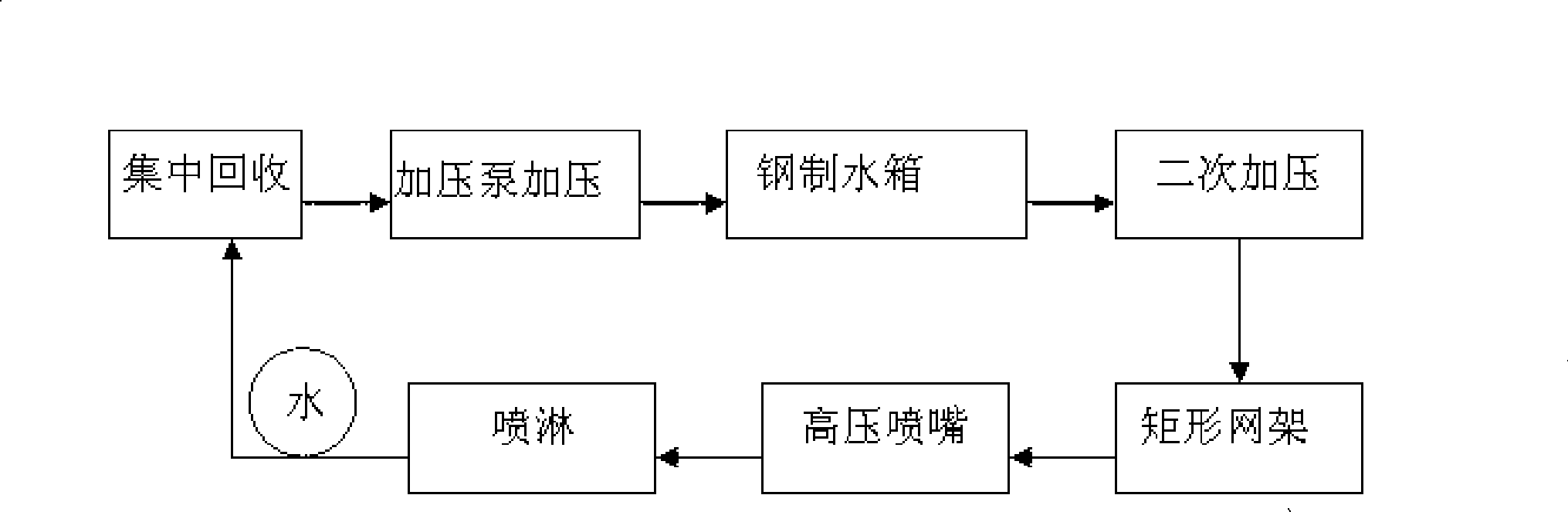

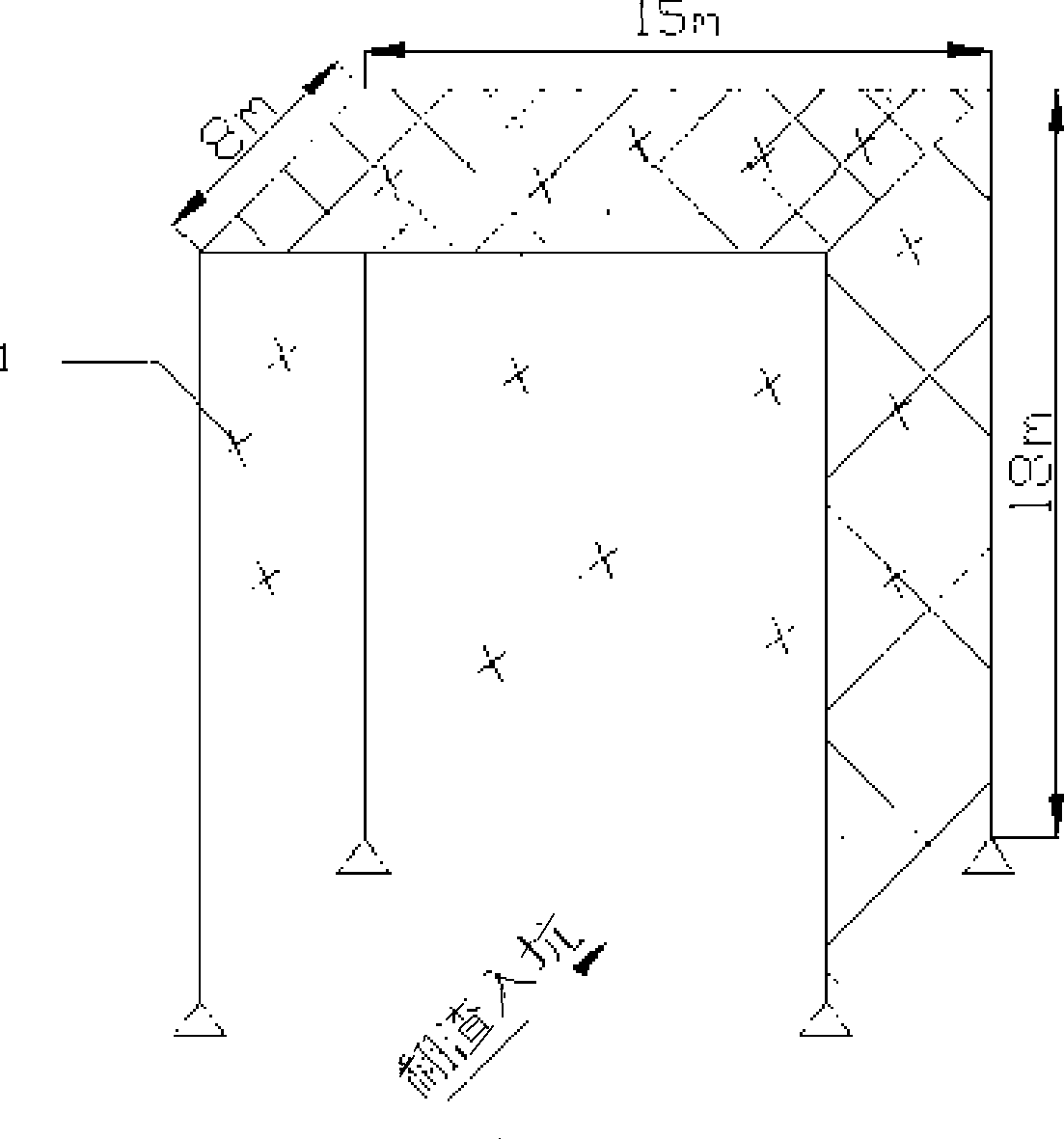

[0018] The high-altitude spraying device adopts a rectangular net frame with a length of 15 meters, a width of 8 meters and a height of 18 meters. The water pressure is 0.6-0.8Mpa, and the nozzle is opened about 1 minute before turning over the slag to form a three-dimensional water curtain. Then turn over 60t of slag and spray the blast furnace slag evenly for 2min. The water after spraying is recycled. The treated high-titanium desulfurized blast furnace slag is crushed, magnetically separated, and recycled.

[0019] Compared with the high-titanium desulfurization blast furnace slag without three-dimensional water curtain spraying, the amount of smoke and dust is reduced by 90%, the floating matter of smoke and dust is reduced by 50%, the area of smoke and dust diffusion is reduced by 80%, and there is no explosion during the spraying process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com