Resin emulsion for cathode electrophoretic coating with high throwing power and preparation method thereof

A cathodic electrophoretic coating, resin emulsion technology, applied in electrophoretic coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor appearance flatness, reduced throwing power, high dependence, etc., and achieve low solvent content and aggregation. The effect of high viscosity and high throwing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

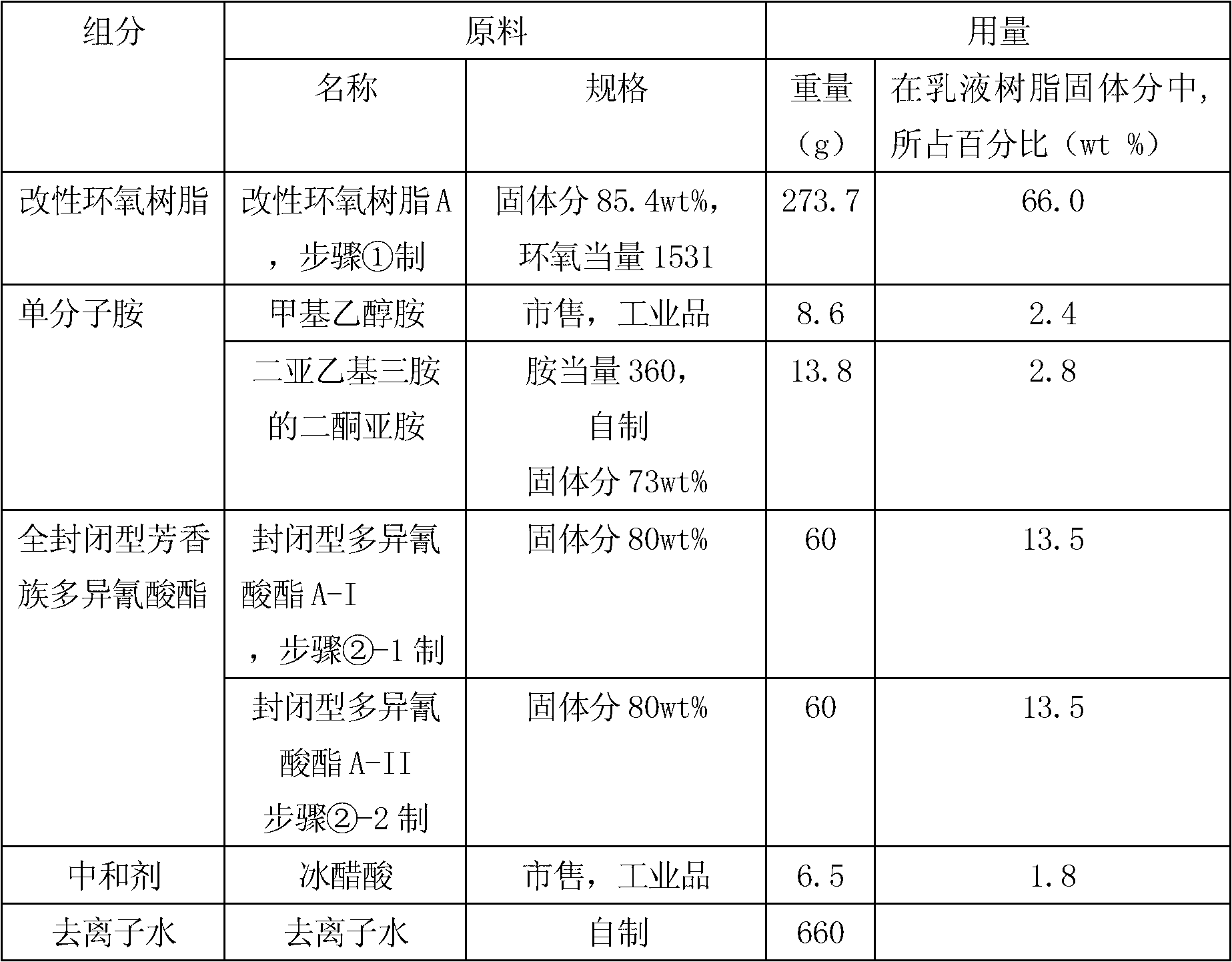

[0025] Embodiment 1 prepares resin emulsion A for cathodic electrophoretic coating with high throwing power

[0026] Concrete preparation steps are as follows:

[0027] ① Preparation of modified epoxy resin A with number average molecular weight of 1500-3000

[0028] In a four-necked flask equipped with a stirrer, a condenser tube, a nitrogen pipe, and a thermometer, add 180 g of bisphenol A epoxy resin EP194 (Shell company product brand) with an epoxy equivalent of 983 and 24 g of solvent methyl isobutyl Ketone, nitrogen, heated together to 110 ° C until the epoxy resin is completely melted, cooled to 90 ° C, added 26.7g of flexible polymer self-made polyether diamine, heated to 120 ° C for chain extension reaction, and kept for 2 hours. After the heat preservation reaction is over, cool down to 100°C, add 27g of plasticizer bisphenol A polyoxyethylene ether BPLE / B (product brand of SEPPIC company) and 16g of solvent methyl isobutyl ketone, and mix well to obtain a number av...

Embodiment 2

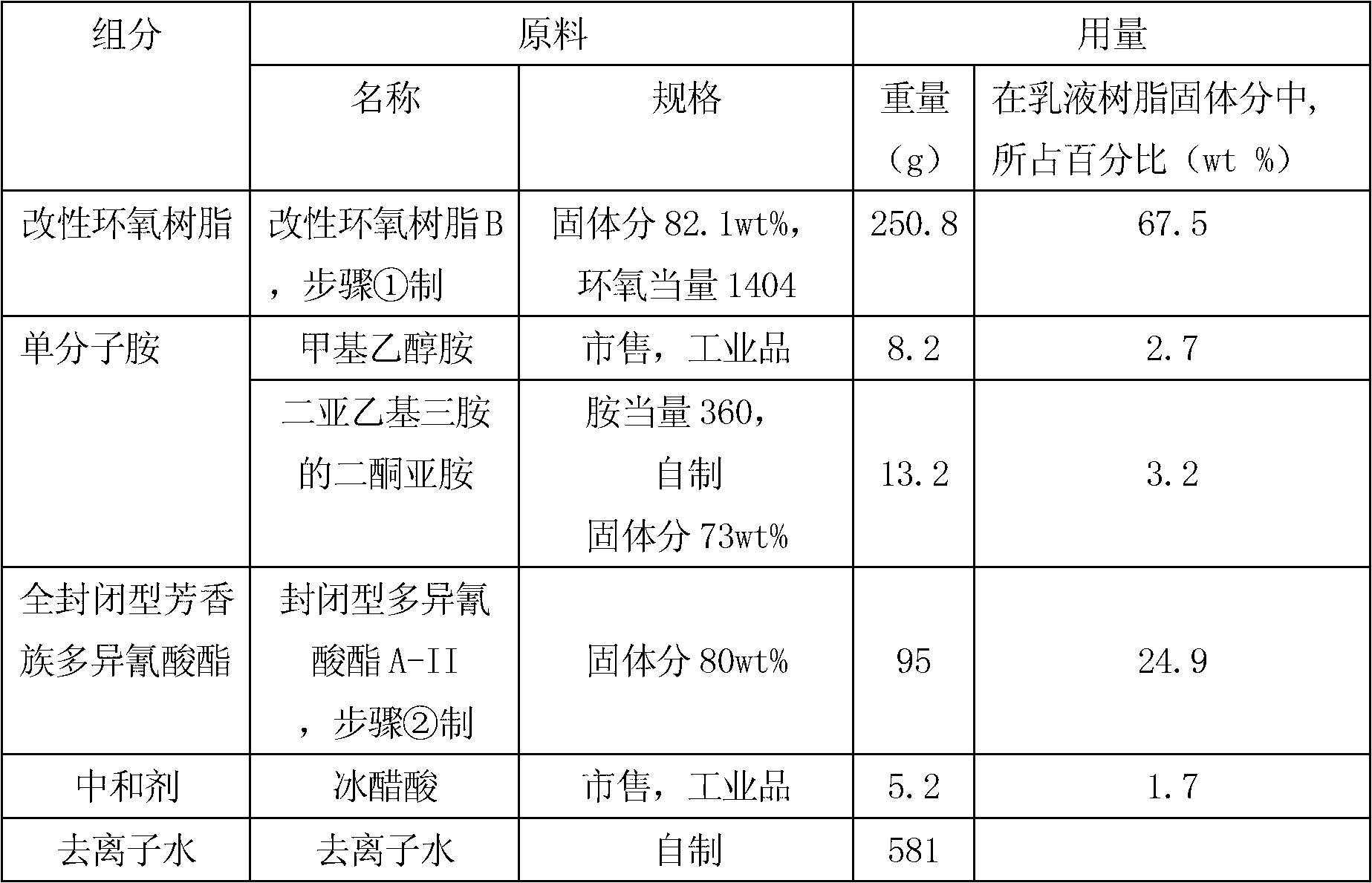

[0041] Embodiment 2 prepares resin emulsion B for cathodic electrophoretic coating with high throwing power

[0042] Concrete preparation steps are as follows:

[0043] ① Preparation of modified epoxy resin B with number average molecular weight of 1500-3000

[0044] In a four-necked flask equipped with a stirrer, condenser, nitrogen pipe, and thermometer, add 140g of bisphenol A epoxy resin 1001 (the product brand of Shell Company) with an epoxy equivalent of 480 and 10g of solvent methyl isobutyl Ketone, blow nitrogen, heat together to 110°C until the epoxy resin is completely melted, then cool down to 90°C, add 39g of flexible polymer polycaprolactone diol PCL205 (product brand of DAICEL company), heat to 140°C and add 0.2g Catalyst N-methylbenzylamine, the mixture is naturally exothermic to 165°C, and kept warm for 0.5 hours, then added 0.6g of catalyst N-methylbenzylamine, continued to keep warm at 165°C for 1.5 hours, after the heat preservation reaction, cooled to 100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com