Molecular glass photoresist containing bisphenol A skeleton structure as well as preparation method and application thereof

A molecular glass and photoresist technology, applied in the application field of extreme ultraviolet lithography, can solve the problems of large molecular weight and non-uniformity, and achieve the effect of easy preservation and good resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of dimethylated tetrabromobisphenol A (I-1A)

[0046]

[0047] Add 5.44g of tetrabromobisphenol A (10mmol) and 2.76g of potassium carbonate (20mmol) into a 150mL three-necked flask, then add 50mL of acetone solvent and 4.26g of methyl iodide (30mmol), and reflux at 50-60°C under argon protection 10~15h. After the reaction was completed, the acetone solvent was evaporated, washed with 50 mL of water, extracted three times with 50 mL of dichloromethane, the organic layers were combined, dried with anhydrous magnesium sulfate, filtered and rotated to obtain a crude product, and passed through silica gel with ethyl acetate / petroleum ether. Column chromatography gave 5.56 g of white solid powder with a yield of 96.2%. EI-MS (C 17 h 16 o 2 Br 4 ), m / z:572. 1 H-NMR (400MHz, CDCl 3 )δ7.30(s,4H), 3.89(s,6H), 1.60(s,6H).

Embodiment 2

[0049] Preparation of 2,2-bis(4-methoxy-3,5-bis(p-methoxyphenyl)phenyl)propane (I-1B)

[0050]

[0051] Add 5.78g of dimethylated tetrabromobisphenol A (10mmol), 9.12g of 4-methoxyphenylboronic acid (60mmol) and 0.58g of tetrakis(triphenylphosphine)palladium into a 250mL three-necked flask, and then add 75mL of 2M Potassium carbonate solution and 75mL dioxane solvent were reacted at 90-100°C for 48h under the protection of argon. After the reaction, the layers were separated, and the organic layer was rotary evaporated to remove the dioxane solvent, washed with 100 mL of distilled water, and extracted three times with 100 mL of dichloromethane; the aqueous layer was extracted three times with 50 mL of dichloromethane. All organic layers were combined, dried with anhydrous magnesium sulfate, filtered and rotary evaporated to obtain a crude product, which was subjected to silica gel column chromatography using dichloromethane as the eluent to obtain 4.68 g of white solid powd...

Embodiment 3

[0053] Preparation of 2,2-bis(4-hydroxy-3,5-bis(p-hydroxyphenyl)phenyl)propane (I-1C)

[0054]

[0055] Add 6.81g of 2,2-bis(4-methoxy-3,5-bis(p-methoxyphenyl)phenyl)propane (10mmol) and 100mL of dichloromethane into a 250mL three-necked flask, 25.0 g of boron tribromide (100 mmol) was added under the protection of argon at ℃, and the reaction was carried out at room temperature for 12 h. After the reaction, the reaction system was added to 100mL 2N NaOH solution, the water layer was separated, acidified with 5N hydrochloric acid, extracted three times with 100mL ethyl acetate, the combined organic layers were dried with anhydrous magnesium sulfate, filtered and rotary evaporated to obtain white crystals 5.36 g, the yield is 89.8%. MALDI-TOF (C 39 h 32 o 6 ), m / z: 596.5. 1 H-NMR(400MHz,DMSO)δ9.39(s,4H),7.71(s,2H),7.28(d,J=5.25Hz,8H),6.97(s,4H),6.78(d,J=5.25 Hz,8H), 1.65(s,6H).

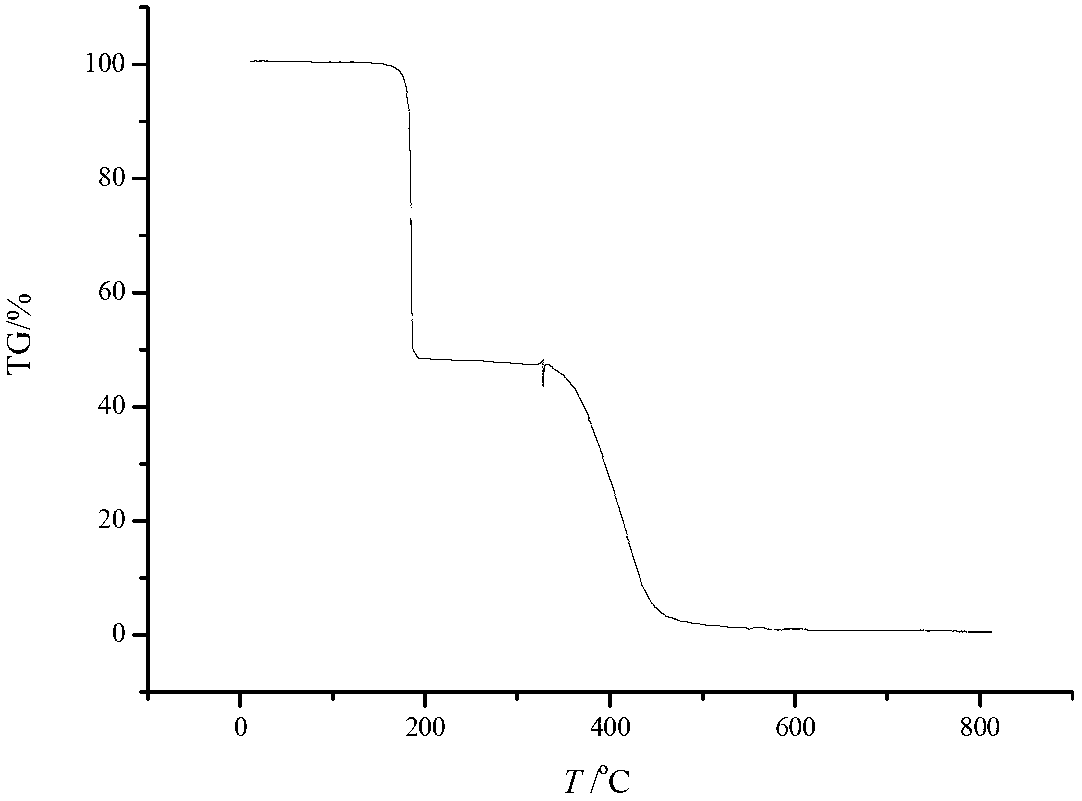

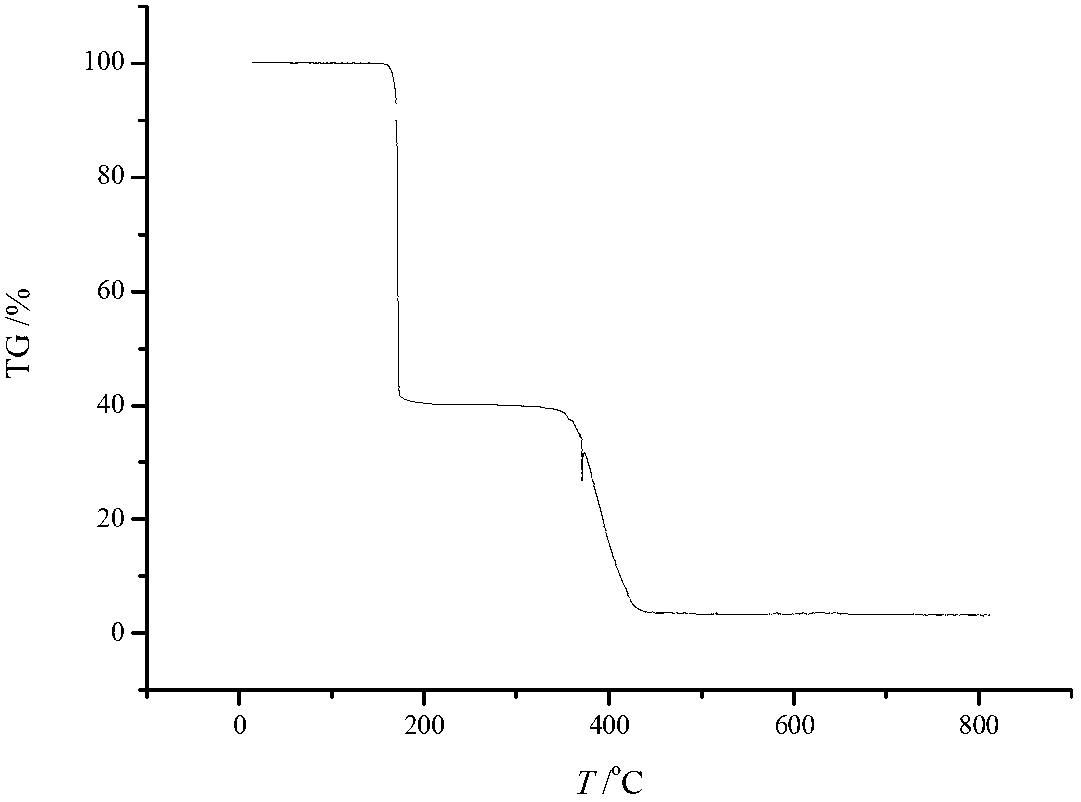

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com