Anti-fouling coating material with excellent compatibility and use thereof

An anti-fouling coating and compatibility technology, applied in anti-fouling/underwater coatings, epoxy resin coatings, coatings, etc., can solve the problem of significant improvement in coating tolerance, achieve excellent adhesion, excellent anti-corrosion Stain performance, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

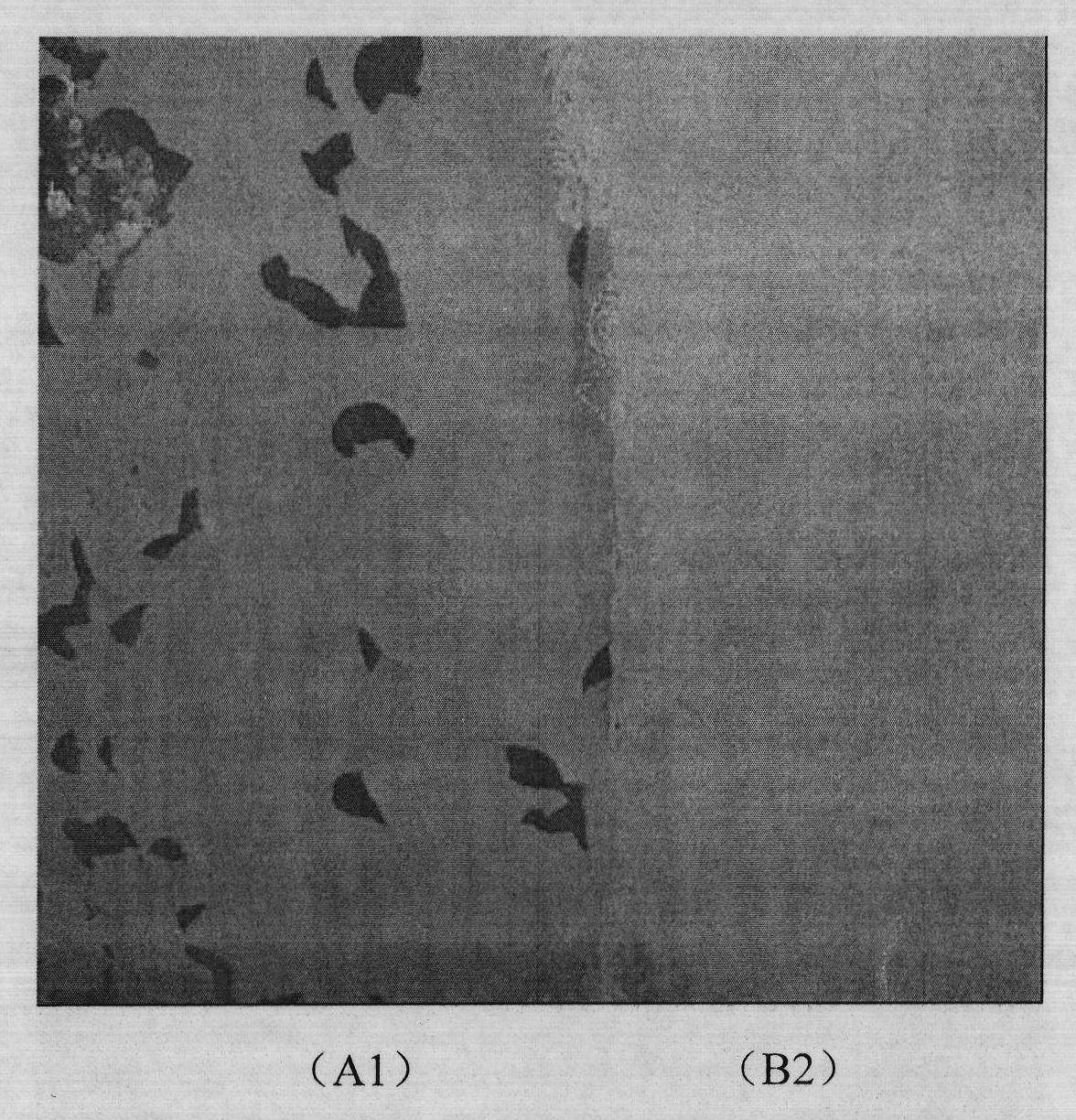

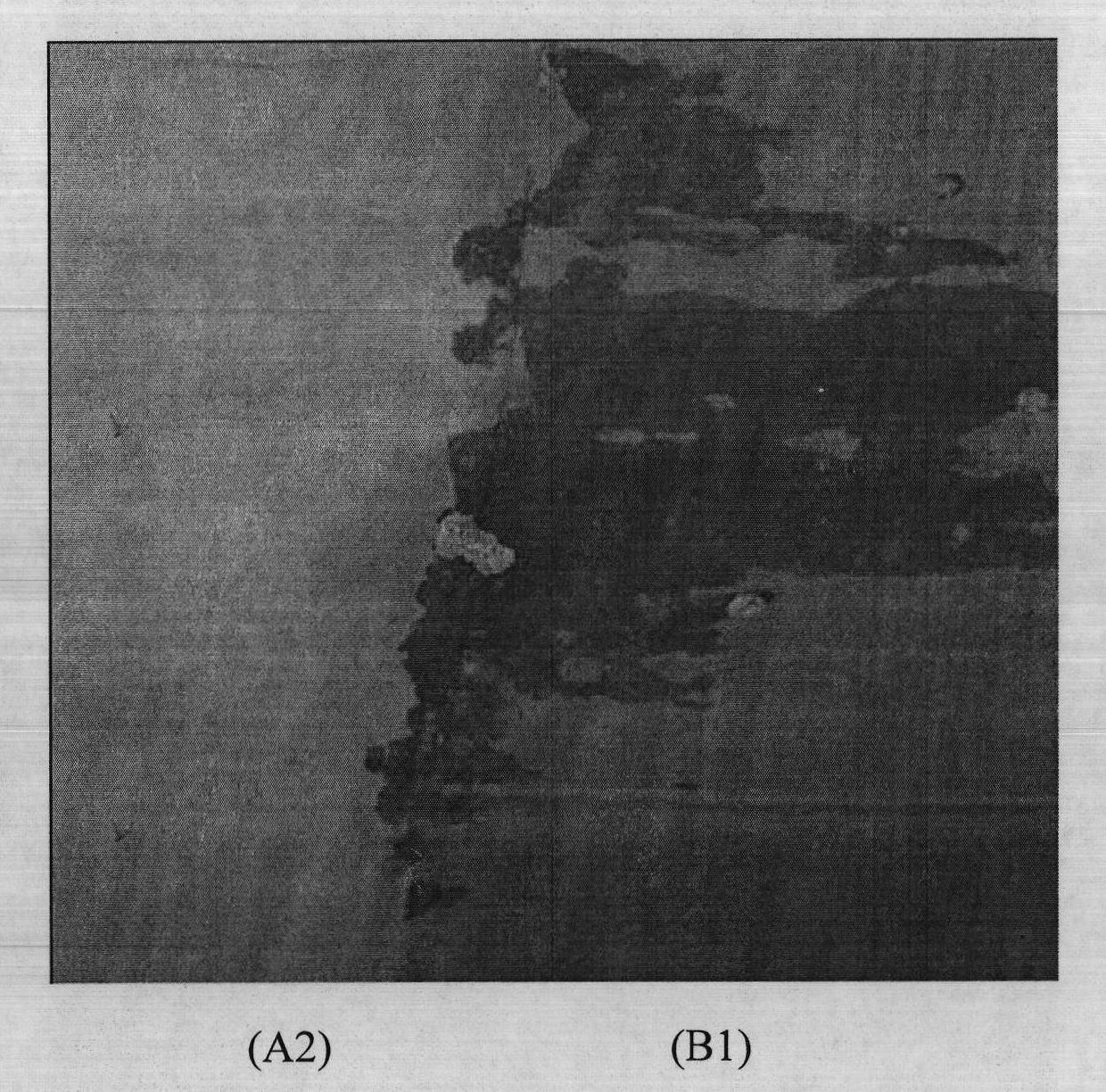

Image

Examples

Embodiment 1

[0045] Embodiment 1: technical scheme of the present invention

[0046] Antifouling coating A2: 94% antifouling coating A1, 5% E44 epoxy resin (epoxy value 0.41~0.47mol / 100g), 1% thermoplastic acrylic resin (methyl methacrylate-ethyl acrylate- acrylamide copolymer).

Embodiment 2

[0047] Embodiment 2: technical scheme of the present invention

[0048] First prepare the polishing type acrylate zinc / copper resin that the present invention uses:

preparation example 1

[0050] In the reactor equipped with stirring, condensing device, dripping device, and thermometer, add 33.5% xylene and 10% propylene glycol monomethyl ether under stirring, add 5% methyl methacrylate, 20% Butyl acrylate, 20% zinc monomethacrylate, 10% acetylacetone, and 1.2% azobisisobutyronitrile were stirred and mixed to prepare a monomer solution. Continue to stir, raise the temperature to 100°C and keep it, add dropwise the prepared monomer solution, control the dropping speed, after 2 hours, add 0.3% azobisisobutyronitrile, control the temperature at 100°C, keep the temperature for 3 hours, and cool to get Polished zinc acrylic resin. The resin is water white and transparent, and its weight-average molecular weight measured by GPC is 4000-20000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com