Irradiation crosslinking low-smoke halogen-free polyolefin cable material as well as preparation method and application thereof

A polyolefin cable material and irradiation technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of high peak and total heat release, incompatibility of flame retardant performance and mechanical performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

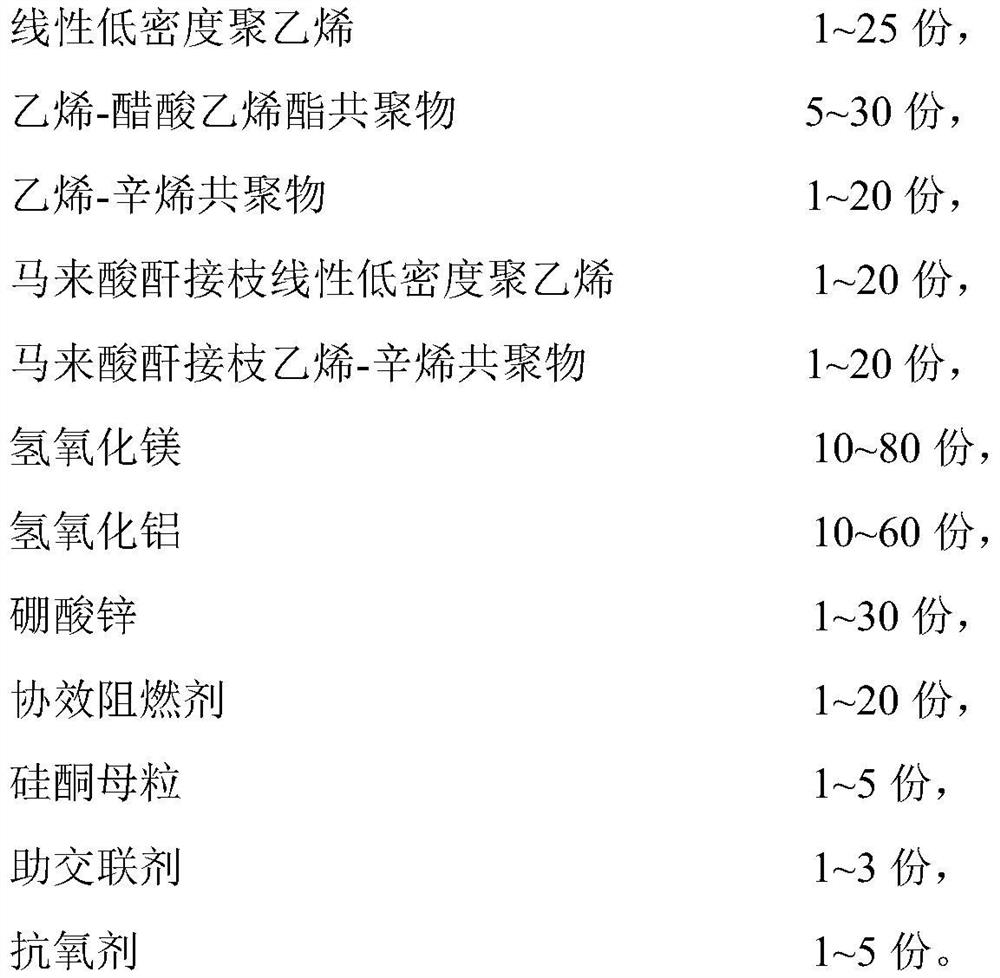

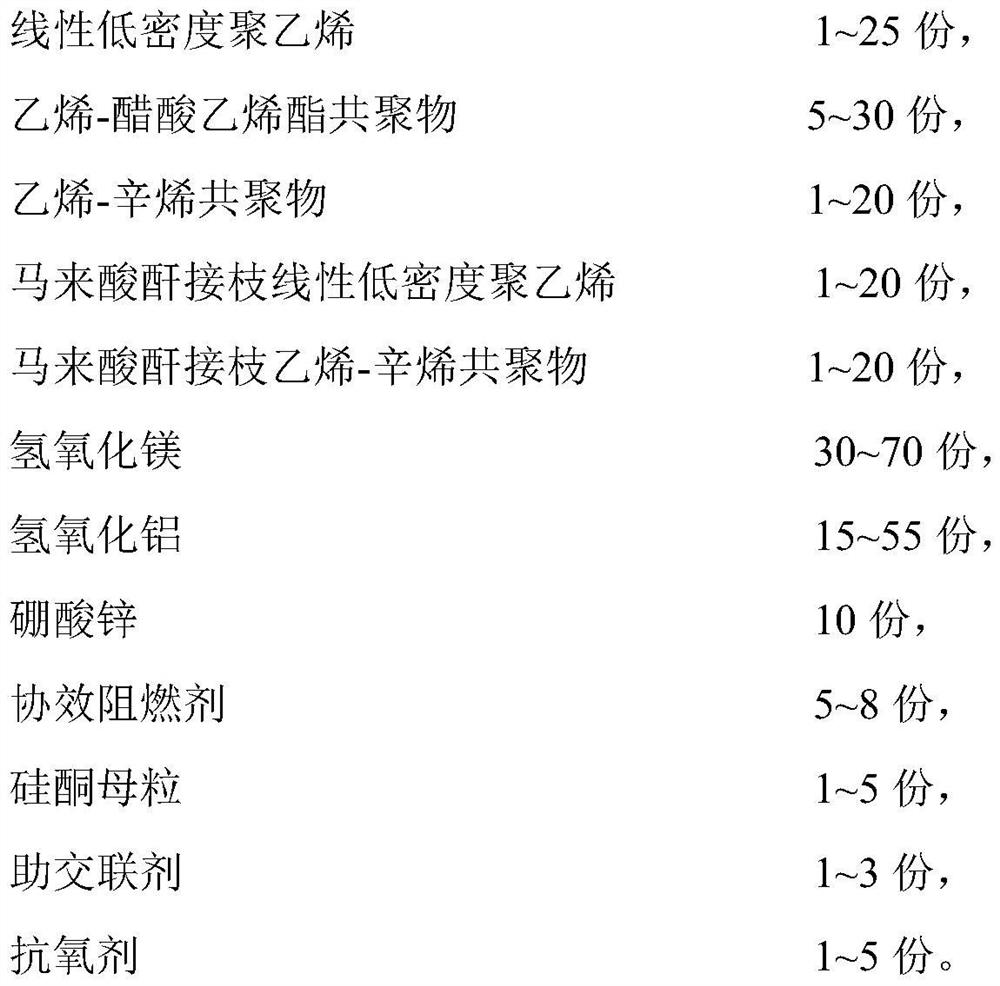

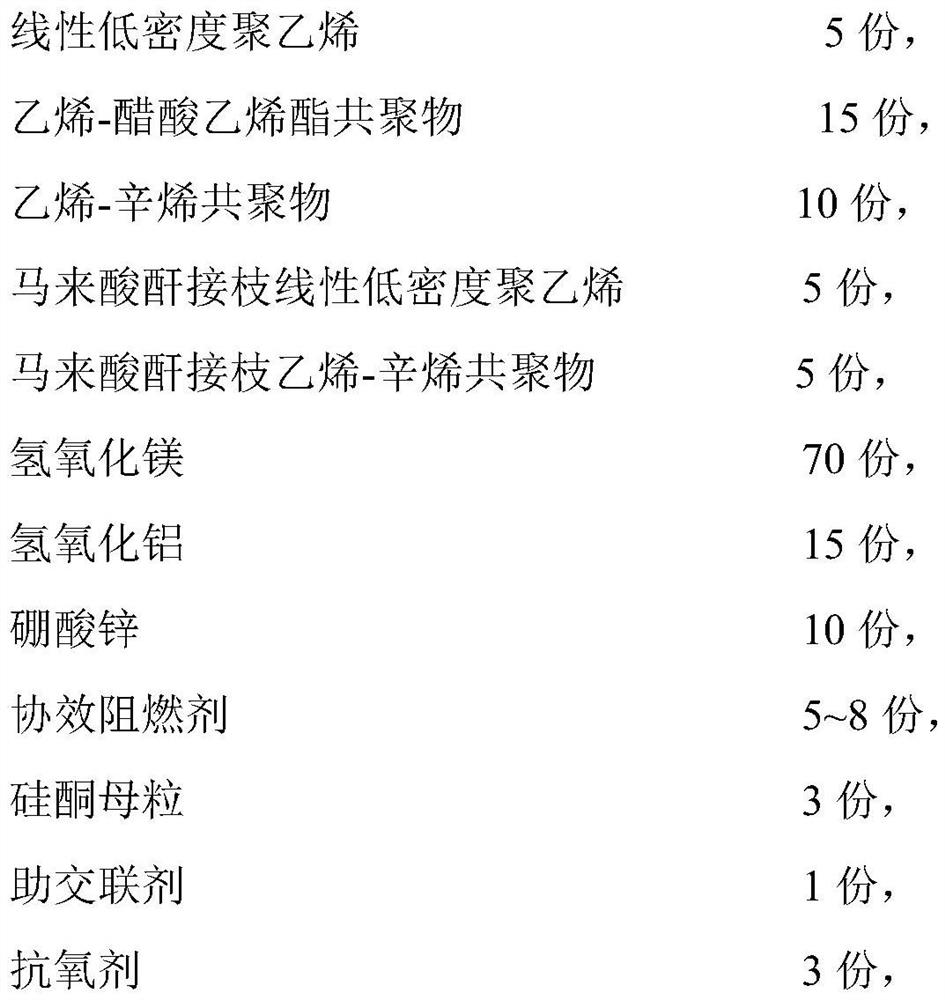

[0107] A radiation cross-linked low-smoke halogen-free polyolefin cable material, including the components shown in Table 1 below in parts by weight.

[0108] The specific preparation method of radiation cross-linked low-smoke halogen-free polyolefin cable material is as follows:

[0109] S1. Put each component into a 400L high-speed mixer and quickly stir and mix evenly. The mixing temperature is 60° C.; the mixing time is 10 minutes, and the speed of the high-speed mixer is 600 rpm;

[0110] S2. Put the uniformly mixed components in S1 into a 75L internal mixer, press down the top bolt, start banburying, banburying into a ball, and banburying temperature is 145°C;

[0111] S3. Put the raw materials after banburying into agglomerates in S2 into the twin-screw extruder for plasticization;

[0112] S4. Putting the plasticized raw materials in S3 into a single-screw extruder to extrude and granulate to prepare the cable material,

[0113] The twin-screw temperature in S3 is 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com