Surface modifying method of hollow glass beads and flame-retardant application thereof

A hollow glass microsphere and surface modification technology, applied in the field of thermoplastic polyurethane elastomer flame retardant modification, can solve the problems of low flame retardant efficiency, large addition amount, and large heat release amount of thermoplastic polyurethane elastomer, and achieve mechanical properties. The effect of small size, low cost and short modification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

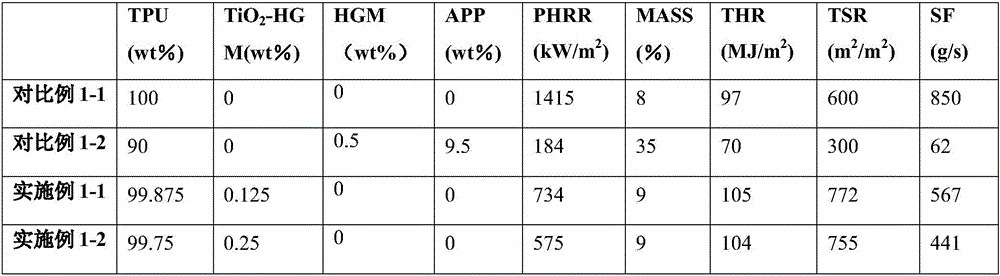

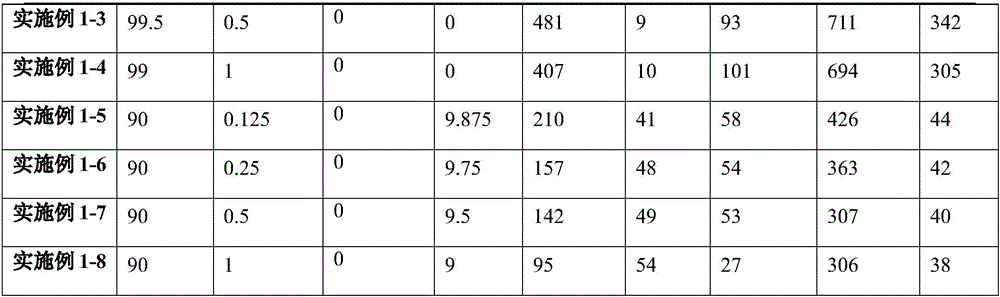

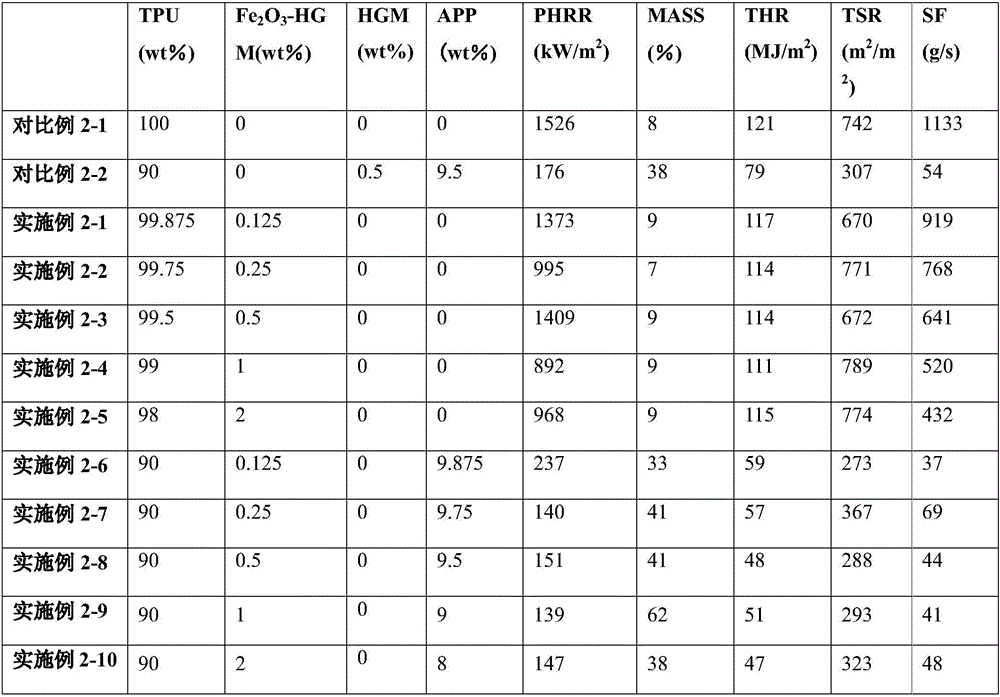

Embodiment 1-1

[0036] Add 99.875% of thermoplastic polyurethane elastomer according to the mass percentage into the internal mixer and banbury for 3 minutes, add 0.125% of the mass percentage of titanium dioxide modified hollow glass microspheres, under room temperature conditions, control the rotating speed to be 10-50r / min, compact Refining for 10 minutes. The resulting material is put into 100×100×3mm 3 In the mould, use a flat vulcanizing machine to press the tablet, control the temperature at 175-180 ° C, hold the pressure for 10-20 minutes, and cool for 1-2 minutes to obtain the product. respectively at 35kW / m 2 , 25kW / m 2 Under the radiant power, the cone calorimeter test and the smoke density test were carried out on the sample, and the peak heat release rate was 734kW / m 2 , the remaining mass is 9%, and the total heat release is 105MJ / m 2 , the total smoke production is 772g, and the smoke factor is 567g / s.

Embodiment 1-2

[0038] Add 99.75% of thermoplastic polyurethane elastomer according to the mass percentage into the internal mixer for banburying for 3 minutes, add 0.25% of the mass percentage of titanium dioxide modified hollow glass microspheres, at room temperature, control the rotating speed to be 10-50r / min, close Refining for 10 minutes. The resulting material is put into 100×100×3mm 3 In the mould, use a flat vulcanizing machine to press the tablet, control the temperature at 175-180 ° C, hold the pressure for 10-20 minutes, and cool for 1-2 minutes to obtain the product. respectively at 35kW / m 2 , 25kW / m 2 Under the radiation power, the cone calorimeter test and the smoke density test were carried out on the sample, and the peak heat release rate was 575kW / m 2 , the remaining mass is 9%, and the total heat release is 104MJ / m 2 , the total smoke production is 755g, and the smoke factor is 441g / s.

Embodiment 1-3

[0040] Add 99.5% of thermoplastic polyurethane elastomer according to the mass percentage into the internal mixer and banbury for 3 minutes, add 0.5% titanium dioxide-modified hollow glass microspheres in the mass percentage, and control the rotating speed at 10-50r / min under room temperature conditions. Refining for 10 minutes. The resulting material is put into 100×100×3mm 3 In the mould, use a flat vulcanizing machine to press the tablet, control the temperature at 175-180 ° C, hold the pressure for 10-20 minutes, and cool for 1-2 minutes to obtain the product. respectively at 35kW / m 2 , 25kW / m 2 Under the radiant power, the cone calorimeter test and the smoke density test were carried out on the sample, and the peak heat release rate was 481kW / m 2 , the remaining mass is 9%, and the total heat release is 93MJ / m 2 , the total smoke production is 711g, and the smoke factor is 342g / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com