Trigger mechanism for self-heating/cooling packages or containers universally applied to both rigid and non-rigid packages and containers

a self-heating/cooling and packaging technology, applied in the direction of exothermal chemical reaction heat production, containers, heating fuel, etc., can solve the problems of reducing the shelf life and efficiency of hot or cold chemical packs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The description which follows, and the embodiments described therein, are provided by way of illustration of an example, or examples, of particular embodiments of the principles of the present invention. These examples are provided for the purposes of explanation, and not limitation, of those principles and of the invention. In the description which follows, like parts are marked throughout the specification and the drawings with the same respective reference numerals.

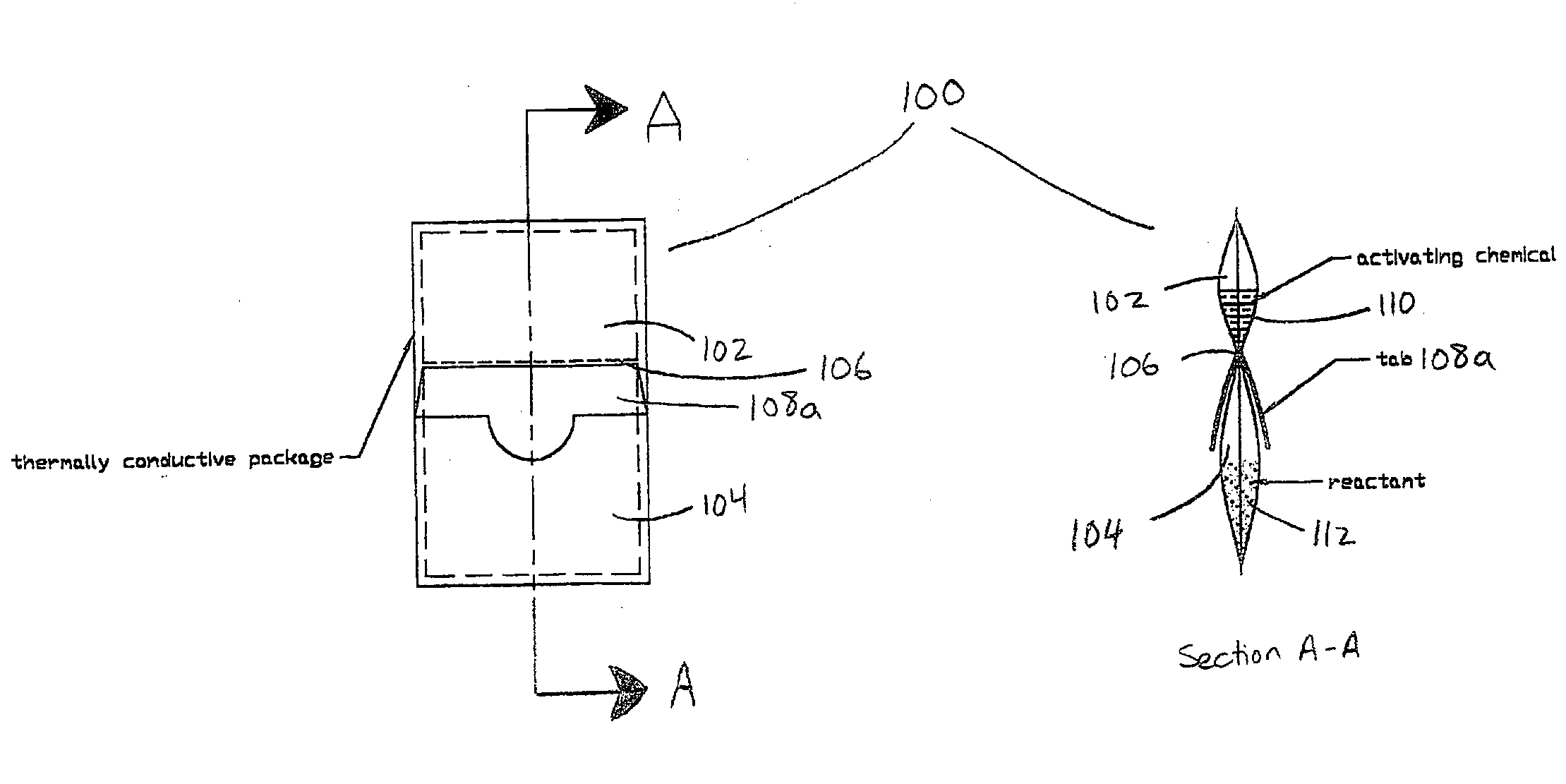

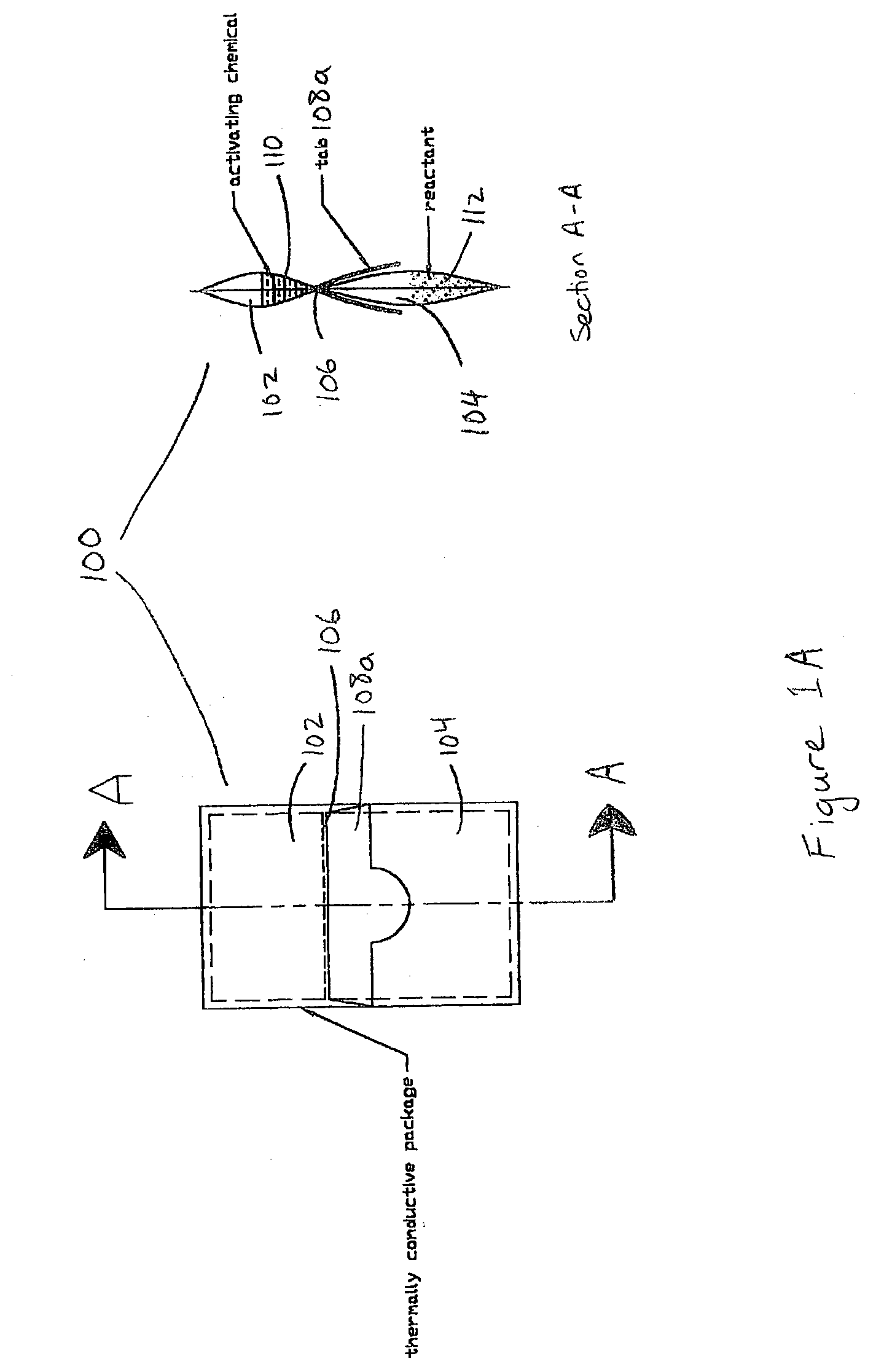

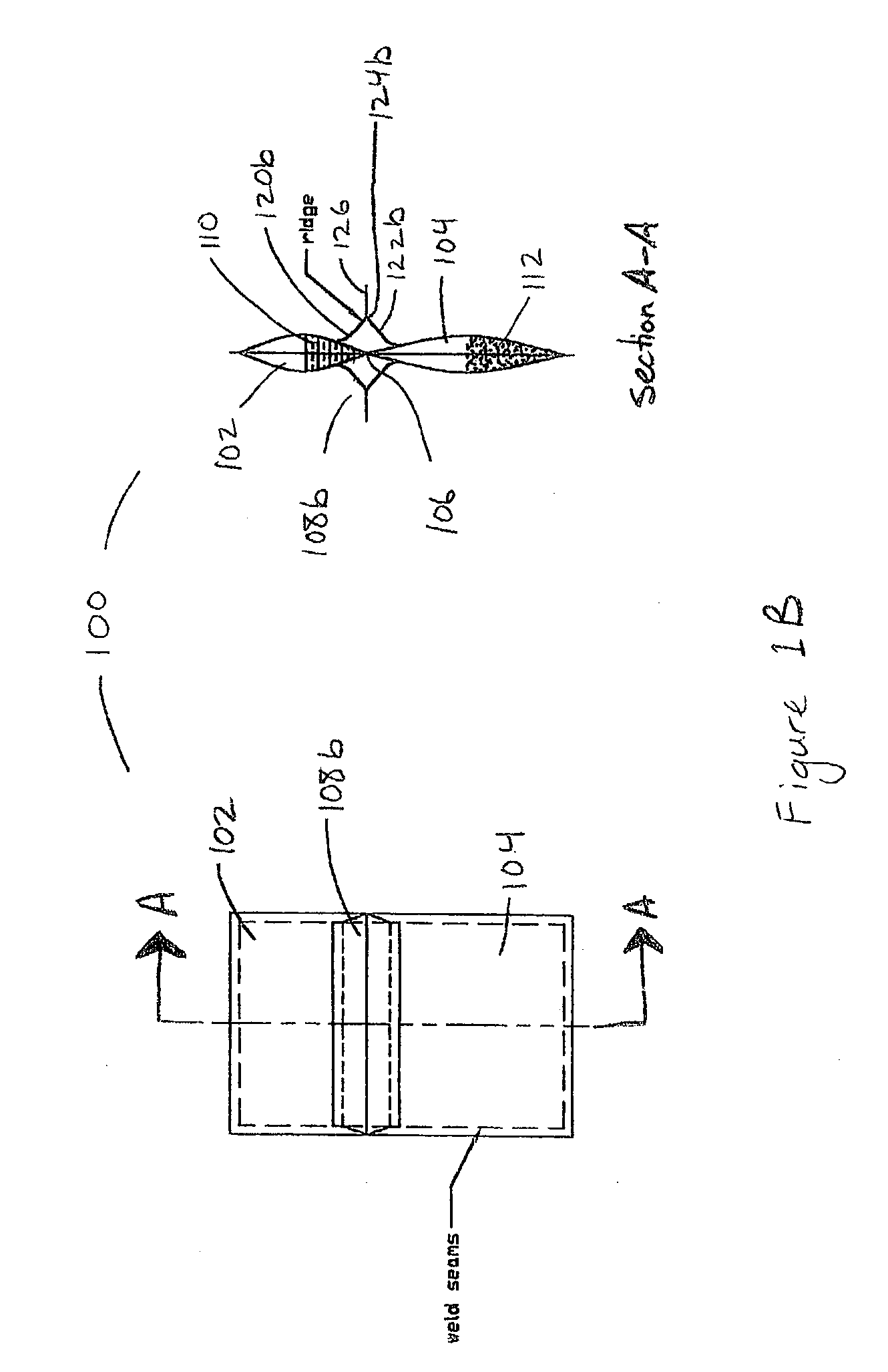

[0053] Briefly, the heating / cooling element of the embodiment includes a triggering mechanism attached adjacent a frangible seal between sealable envelopes containing agents or attached to each envelope containing agents. The triggering mechanism may provide complete, uniform breakage of the frangible seal as opposed to the rupturable or squeezable counterpart of the prior art which usually breaks at a point. This enables quicker and more complete mixing of chemicals in the embodiment and may increase the size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com