Loop heat-conducting device

A loop and loop tube technology, applied in the field of heat conduction devices, can solve the problems of internal working fluid circulation failure, loop heat pipe drying up, and inability to provide working fluid backflow in a timely manner, so as to overcome the reverse gravity operation, improve capillary force, and optimize The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical characteristics of the present invention will be further described in conjunction with the following examples. These examples are only examples of preferred representatives, and are not intended to limit the scope of the present invention. The best understanding of the present invention is obtained by referring to the accompanying drawings in conjunction with the following detailed description.

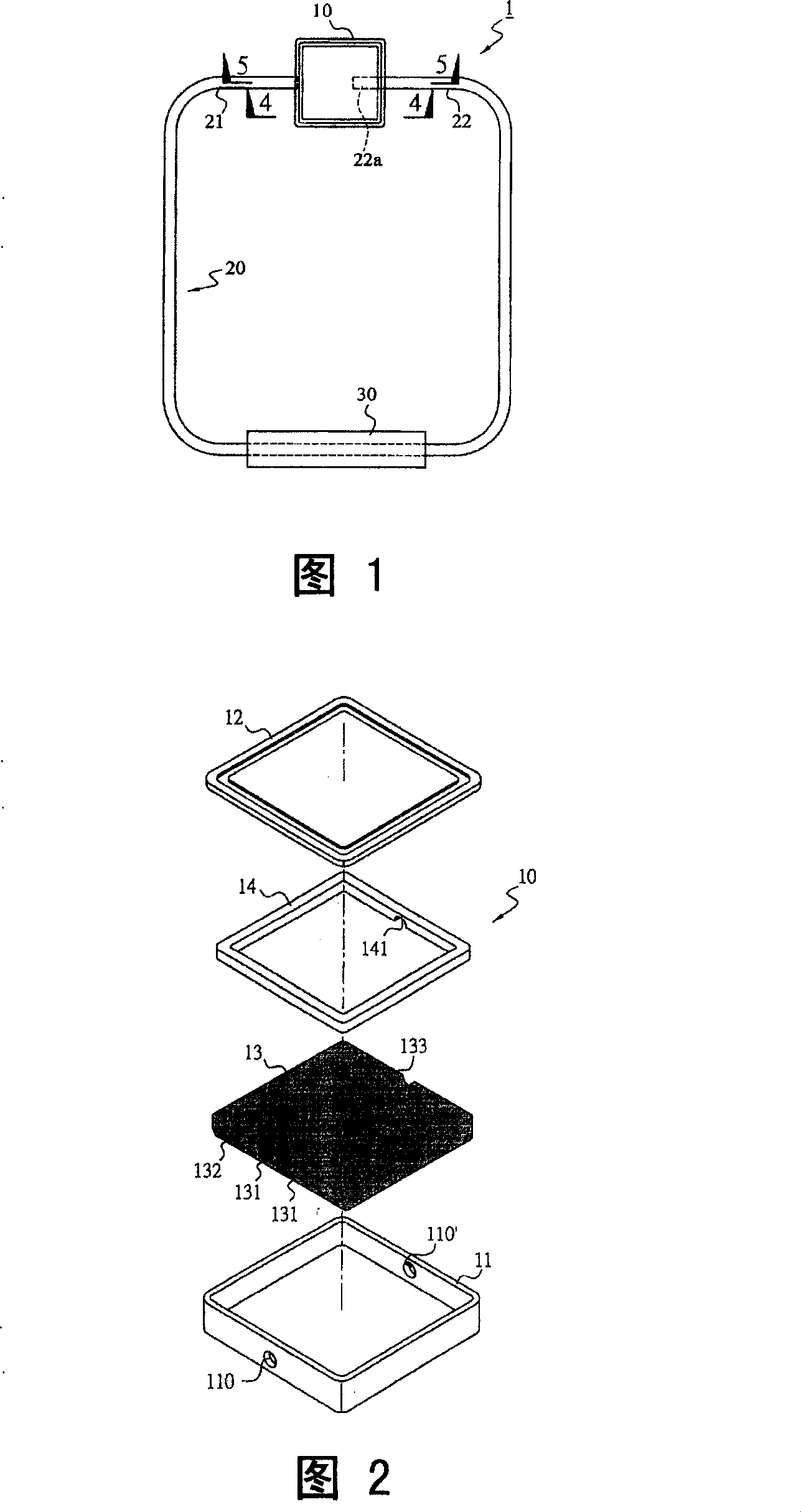

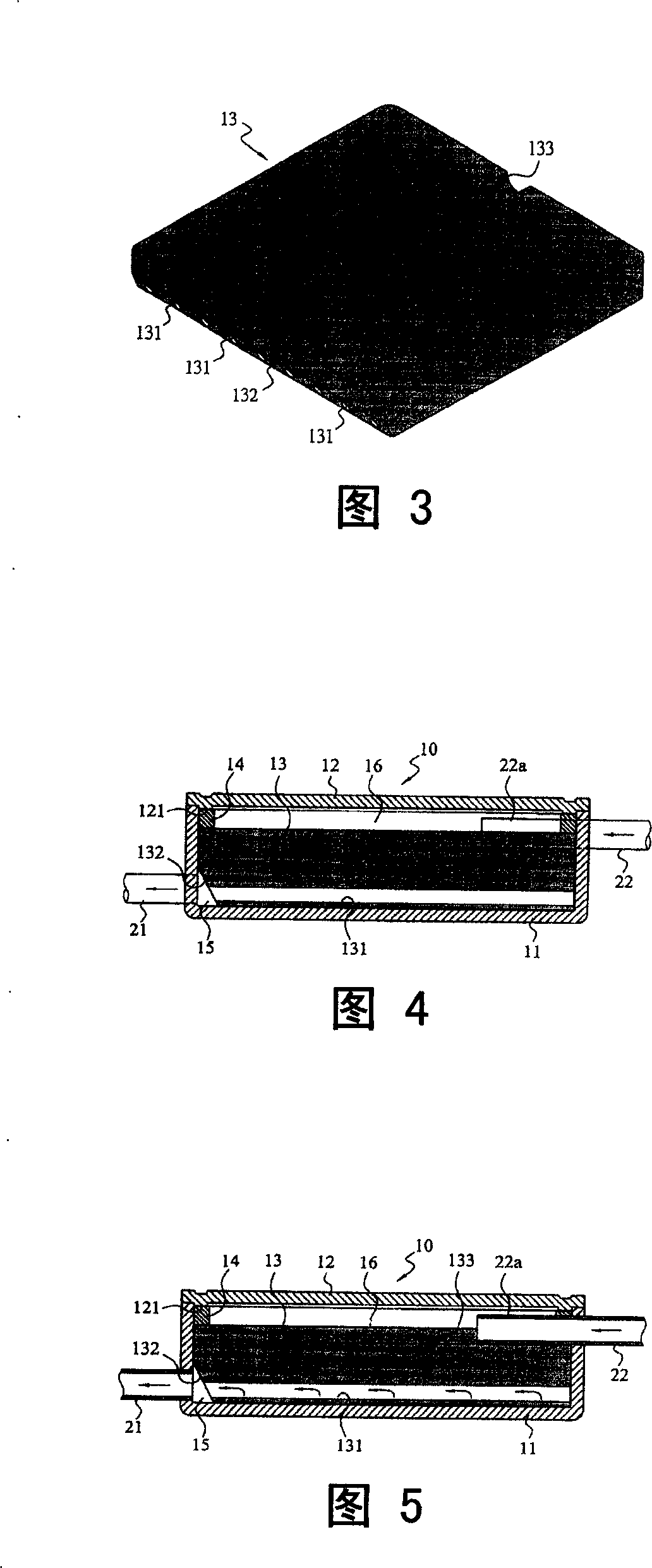

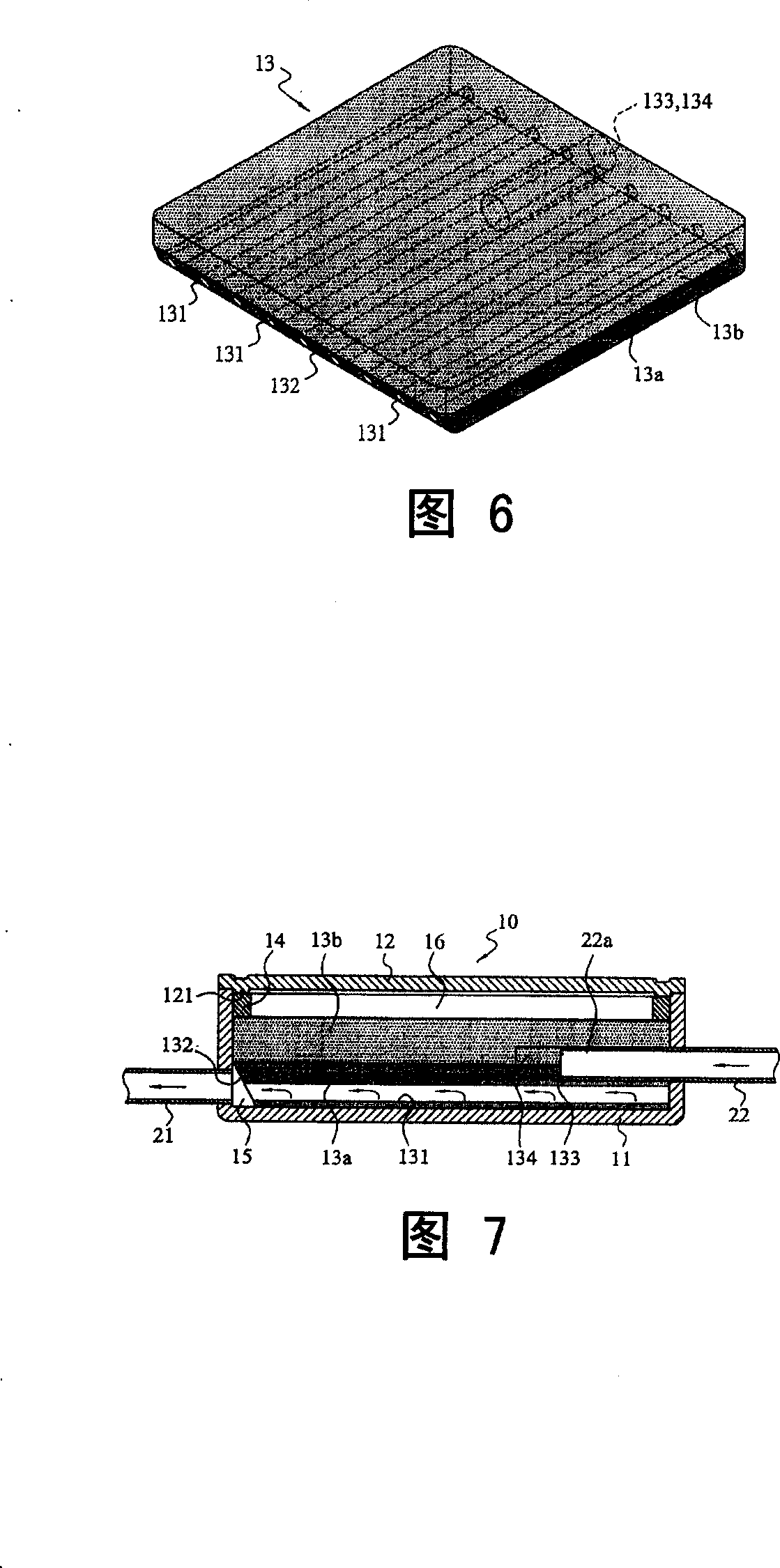

[0020] First, referring to Fig. 1 to Fig. 5, it is an embodiment of the loop heat conduction device 1 of the present invention, as shown in Fig. 1, it basically includes an evaporator 10 and a condenser 30, and a loop pipe 20 is passed between the two. Connected to form a circulation loop of the fluid working medium. FIG. 2 is an exploded perspective view of the evaporator 10 of the present invention. FIG. 3 is a perspective view of the first embodiment of the capillary tissue core 13 of the present invention. 4 and 5 are cross-sectional views of the capillary st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com