Three-dimensional printing variable-filling method based on contour features

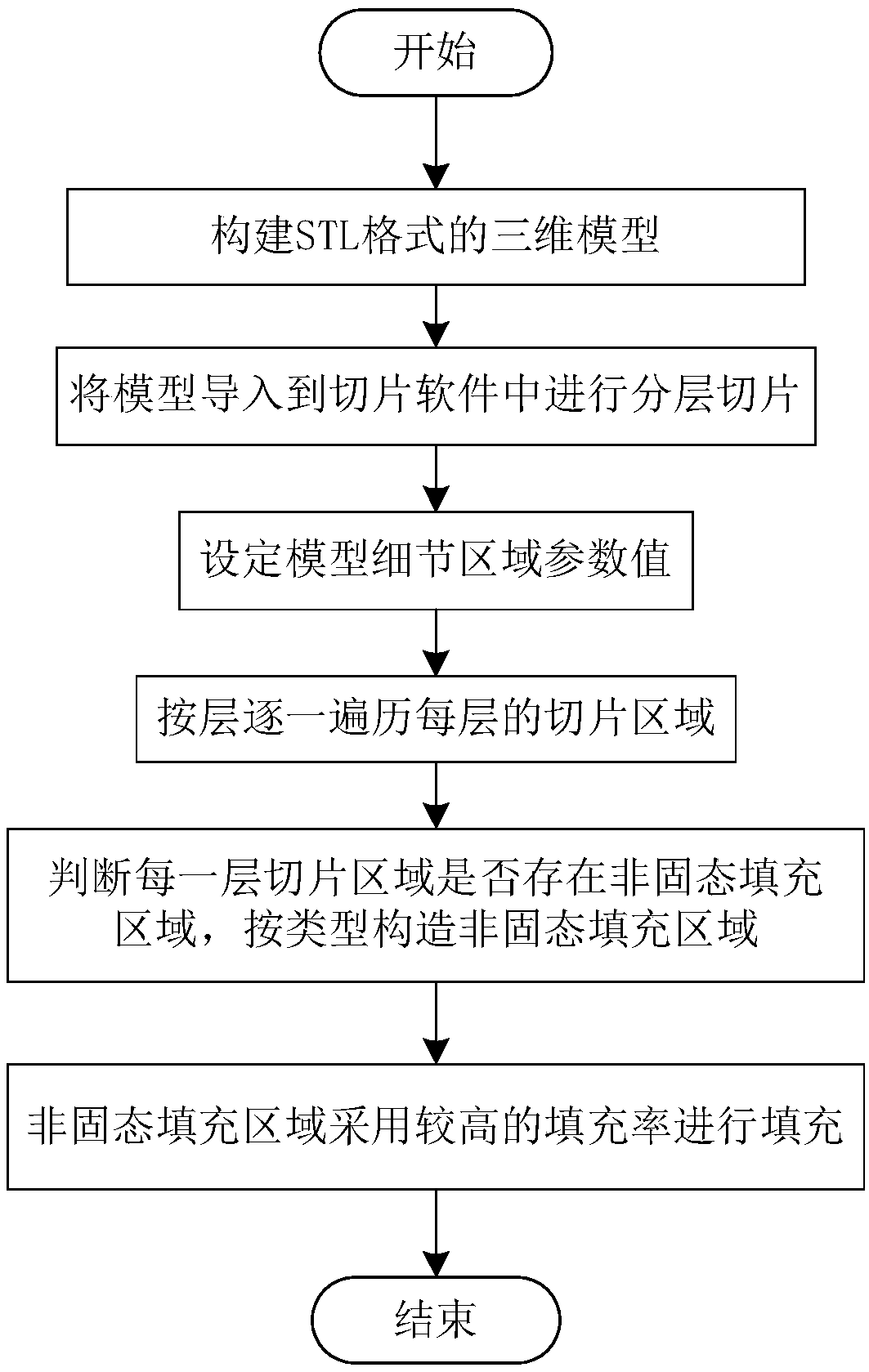

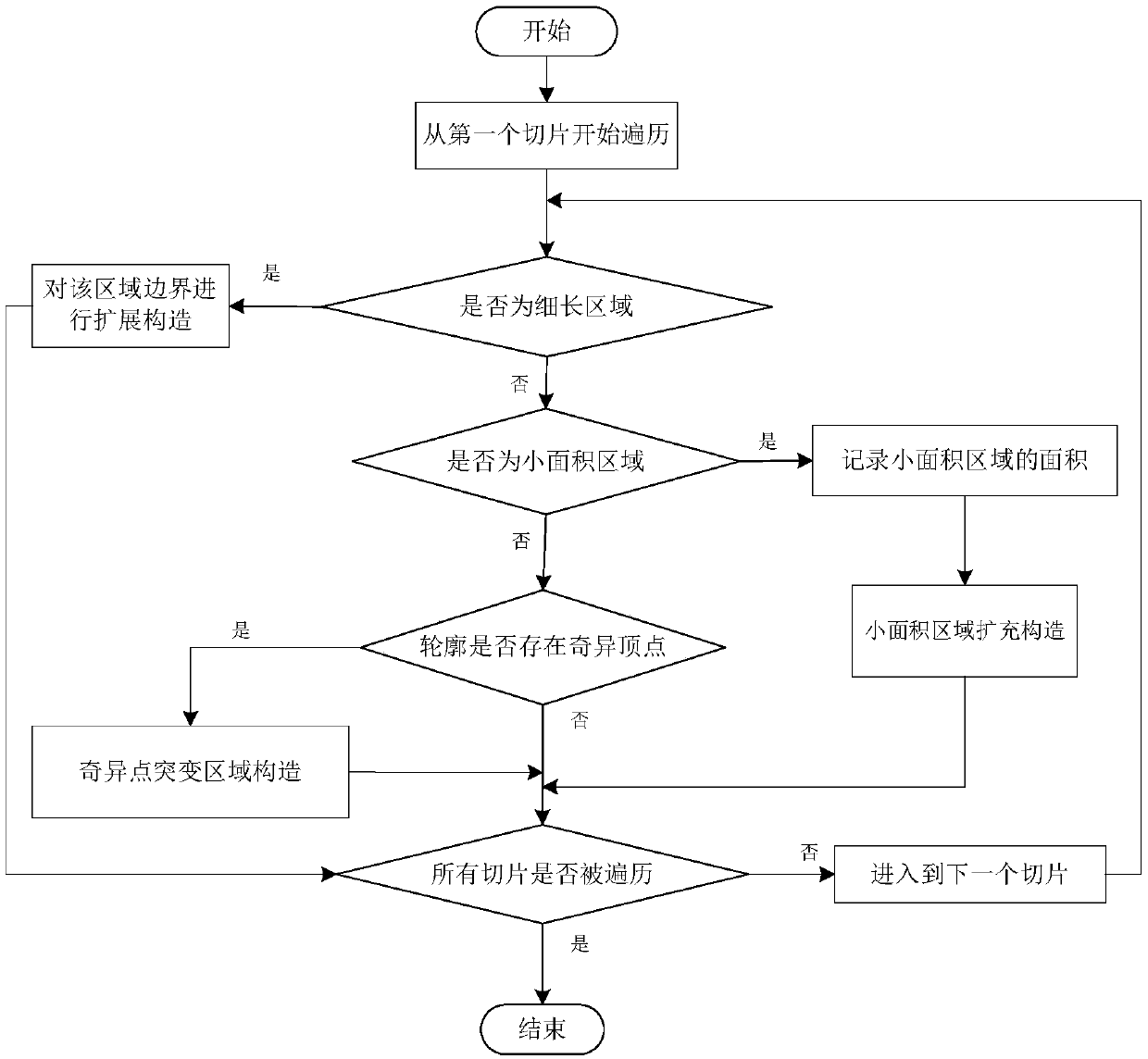

A technology of three-dimensional printing and filling method, which is applied in the direction of additive manufacturing, 3D object support structure, processing data acquisition/processing, etc. It can solve the problems that the strength cannot be guaranteed and prolong the printing time of the model, so as to ensure the structural strength of the model and reduce the size of the model. The effect of molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Embodiment 1 is an embodiment of the slender area, the filling rate of the solid filling area is set to 10%, the filling rate of the extended area of the slender area is 60%, and the length threshold of the cross-scanning line algorithm is L 阈 is 4 mm, the area threshold S of the small area area 阈 is 25 square millimeters, and the small-area expansion area is constructed on the sample group at the same time to obtain the multi-slice layer expansion area of the small-area area. After slicing, the simulation results of the 15th layer of the sample group are shown in Figure 9(a). The printed sample of the 15th layer of the sample group is shown in Figure 9(b).

Embodiment 2

[0104] Embodiment 2 is an embodiment of a sudden change region. The contour of the sample slice layer is a quadrilateral containing four vertices. If the convex vertex is an acute angle, then the position of the vertex is constructed with a sudden change region. The simulation diagram of the 22nd slice layer of the model is as follows Figure 10 As shown, the printed object of the 22nd slice layer of the model, such as Figure 10 shown.

Embodiment 3

[0106] Embodiment 3 is an embodiment of a small-area area, the number of projection layers is set to 4, and the length threshold L 阈 is 4 mm, the area threshold S of the small area area 阈 It is 25 square millimeters, the solid filling rate is 10%, and the non-solid filling rate is 100%. Print the animal dog entity and minion entity, and stop printing after printing to the corresponding slice layer to get the actual printing effect of the filled area. The animal dog simulation model is shown in Figure 11(a), and the minion simulation model is shown in Figure 11(b). Figure 12(a) shows the 60th slice layer of Animal Dog, the 64th slice layer of Animal Dog is shown in Figure 12(b), and the 83rd slice layer of Animal Dog is shown in Figure 12(c). Figure 13(a) shows the 20th slice layer of the Minions, the 26th slice layer of the Minions is shown in Figure 13(b), and the 30th slice layer of the Minions is shown in Figure 13(c) , the minion's 26th unprocessed slice layer is shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com