Regeneration technology of V-Ti-based honeycomb SCR denitration catalyst, and apparatus thereof

A denitration catalyst and honeycomb technology are applied in the regeneration process of vanadium-titanium-based honeycomb selective catalytic reduction denitration catalyst and the field of regeneration devices, which can solve the problems of hidden dangers, secondary pollution, long treatment time, etc., and achieve the control of NOx, The effect of saving replacement costs and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

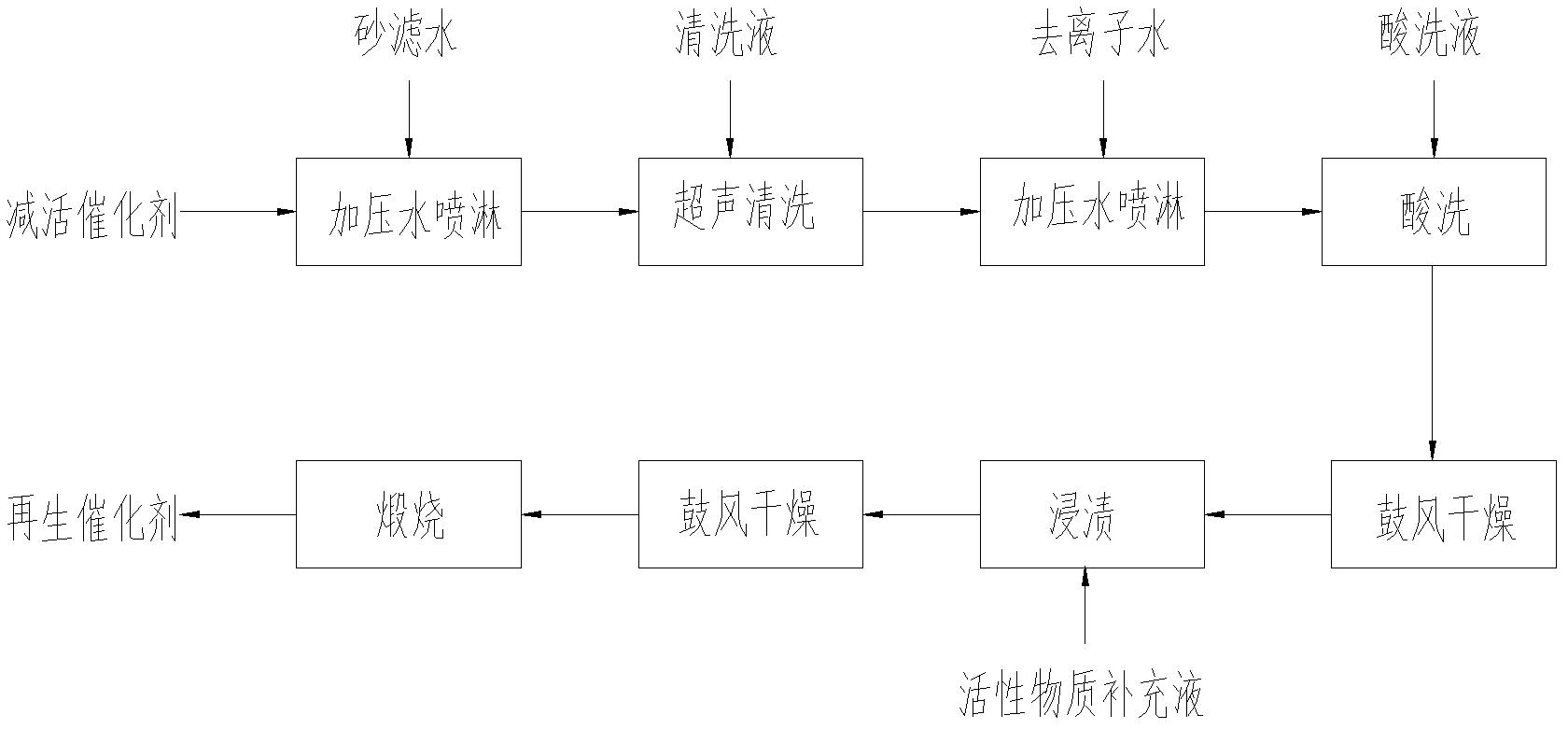

Method used

Image

Examples

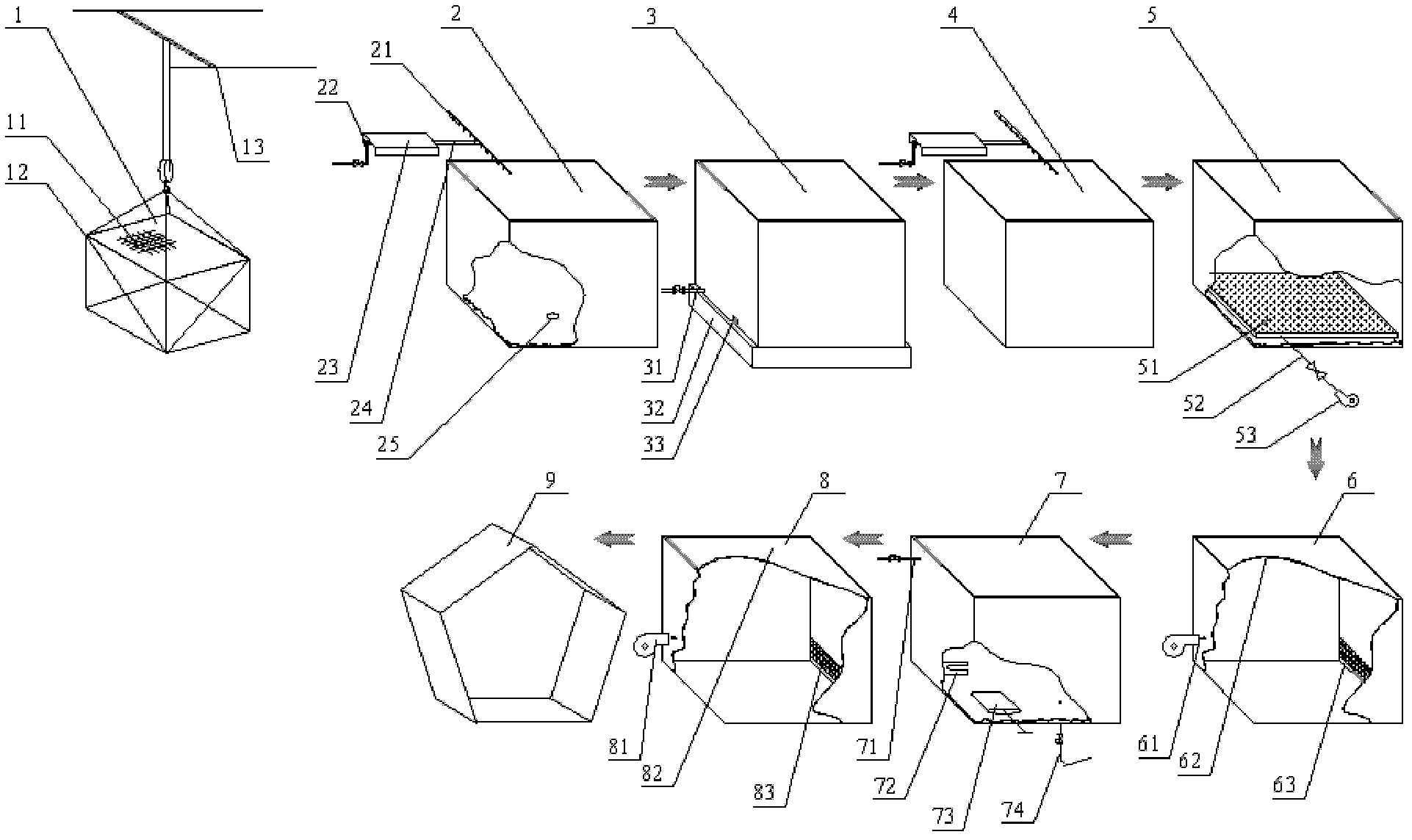

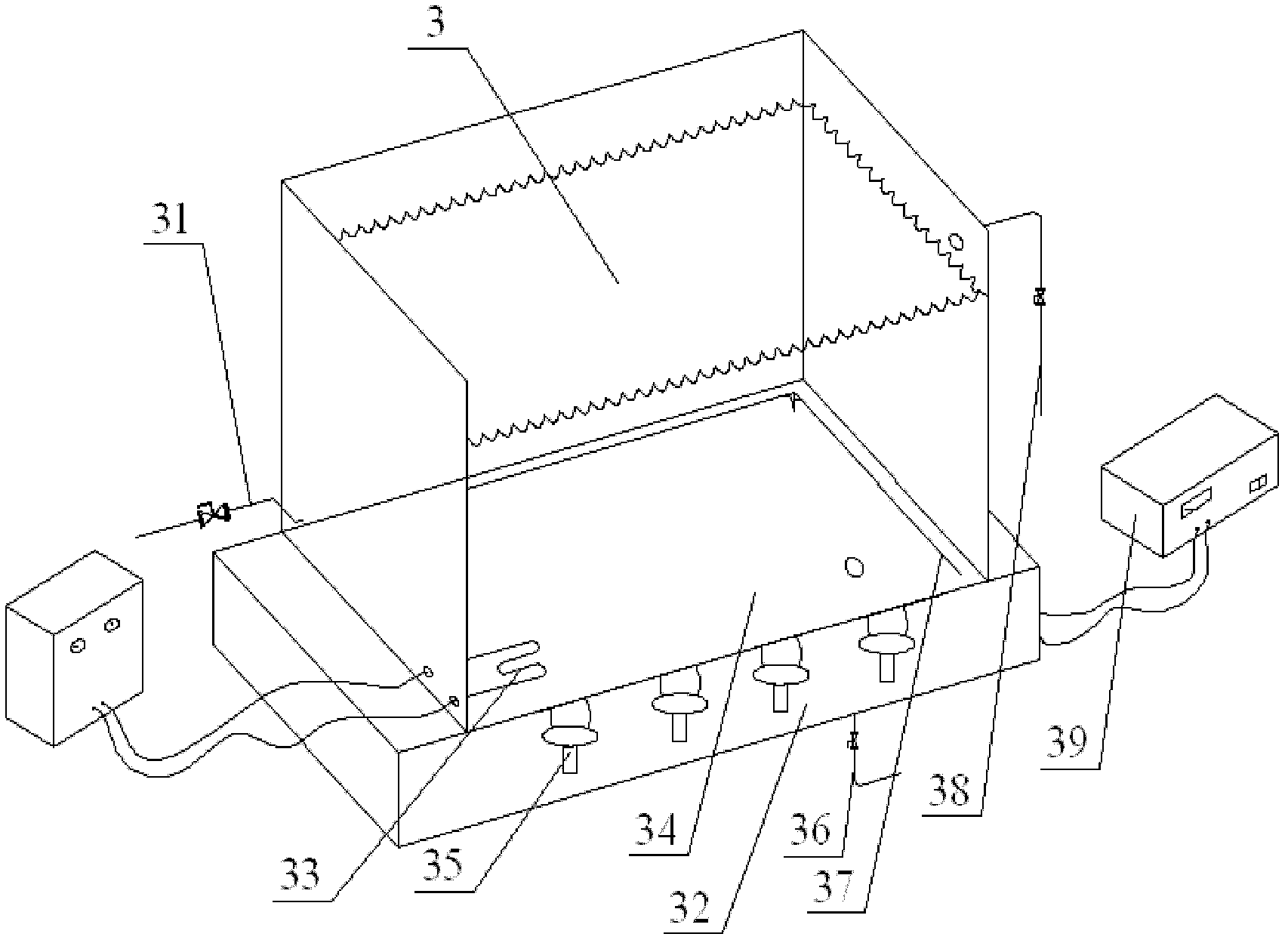

Embodiment 1

[0029] Adopt the deactivated vanadium-titanium-tungsten honeycomb Denitrification catalyst. The main components of the catalyst are vanadium, titanium and tungsten. The cross-sectional size of the catalyst is 150mm×150mm. Cut a piece of 40mm×40mm×40mm, and first spray it with pressurized sand filter water for 10 minutes. Then put it in a constant temperature water bath ultrasonic cleaner, at a cleaning frequency of 32kHz, 10kW / m 2 The sound intensity is 40°C for 8 minutes. The composition of the cleaning solution is HPMA (mass percentage concentration is 0.5‰). Spray with deionized water for 5 min after ultrasonic cleaning. Then put it into a solution containing 10g / L sulfuric acid and 0.4‰ oxalic acid for pickling, and bubbles are blown into the bottom of the pickling device. Then put it into a blast drying oven to dry for 20min. The dried catalyst is put into a solution containing 0.1 mol / L vanadyl sulfate and 0.15 mol / L ammonium metatungstate, the pH value of the solut...

Embodiment 2

[0037] Cut a piece of 40mm×40mm×40mm from the catalyst in Example 1, and first use pressurized sand to filter water and spray for 10 minutes. Then put it in a constant temperature water bath ultrasonic cleaner, at a cleaning frequency of 20kHz, 20kW / m 2 sound intensity, wash at 35°C for 10 minutes. The composition of the cleaning solution is HPMA (mass percentage concentration is 0.5‰). Spray with deionized water for 5 min after ultrasonic cleaning. Then put it into a solution containing 50g / L sulfuric acid and 0.4‰ oxalic acid for pickling, and bubbles are blown into the bottom of the pickling device. Then put it into a blast drying oven to dry for 20min. The dried catalyst is put into a solution containing 0.15 mol / L vanadyl sulfate and 0.2 mol / L ammonium metatungstate, the pH value of the solution is adjusted to 2 with sulfuric acid, and the solution is stirred for impregnation. The impregnated catalyst was dried in a blast drying oven for 20 minutes, then placed in a m...

Embodiment 3

[0043] A piece of 40mm×40mm×40mm was cut from the denitration catalyst in Example 1, and was first sprayed with pressurized sand for 5 minutes. Then put it in a constant temperature water bath ultrasonic cleaner, at a cleaning frequency of 18kHz, 20kW / m 2 sound intensity, wash at 40°C for 10 minutes. The composition of the cleaning solution is HPMA (mass percentage concentration is 0.5‰). Spray with deionized water for 5 minutes after cleaning. Then put it into a solution containing 25g / L sulfuric acid and 0.2‰ gallic acid for pickling, and bubbles are blown into the bottom of the pickling device. Then put it into the blast drying oven to dry for 20min. The dried catalyst is put into a solution containing 0.15 mol / L vanadyl sulfate and 0.2 mol / L ammonium metatungstate, the pH value of the solution is adjusted to 2.5 with sulfuric acid, and the solution is stirred for impregnation. The impregnated catalyst was dried in a blast drying oven for 20 minutes, then put into a muf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com