Frame for LED display screen

A LED display screen and frame technology, which is applied in rack/frame structures, instruments, identification devices, etc., can solve the problems of low work efficiency, single use function, high manufacturing cost, etc., and achieve convenient assembly or maintenance, diverse use functions, The effect of ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

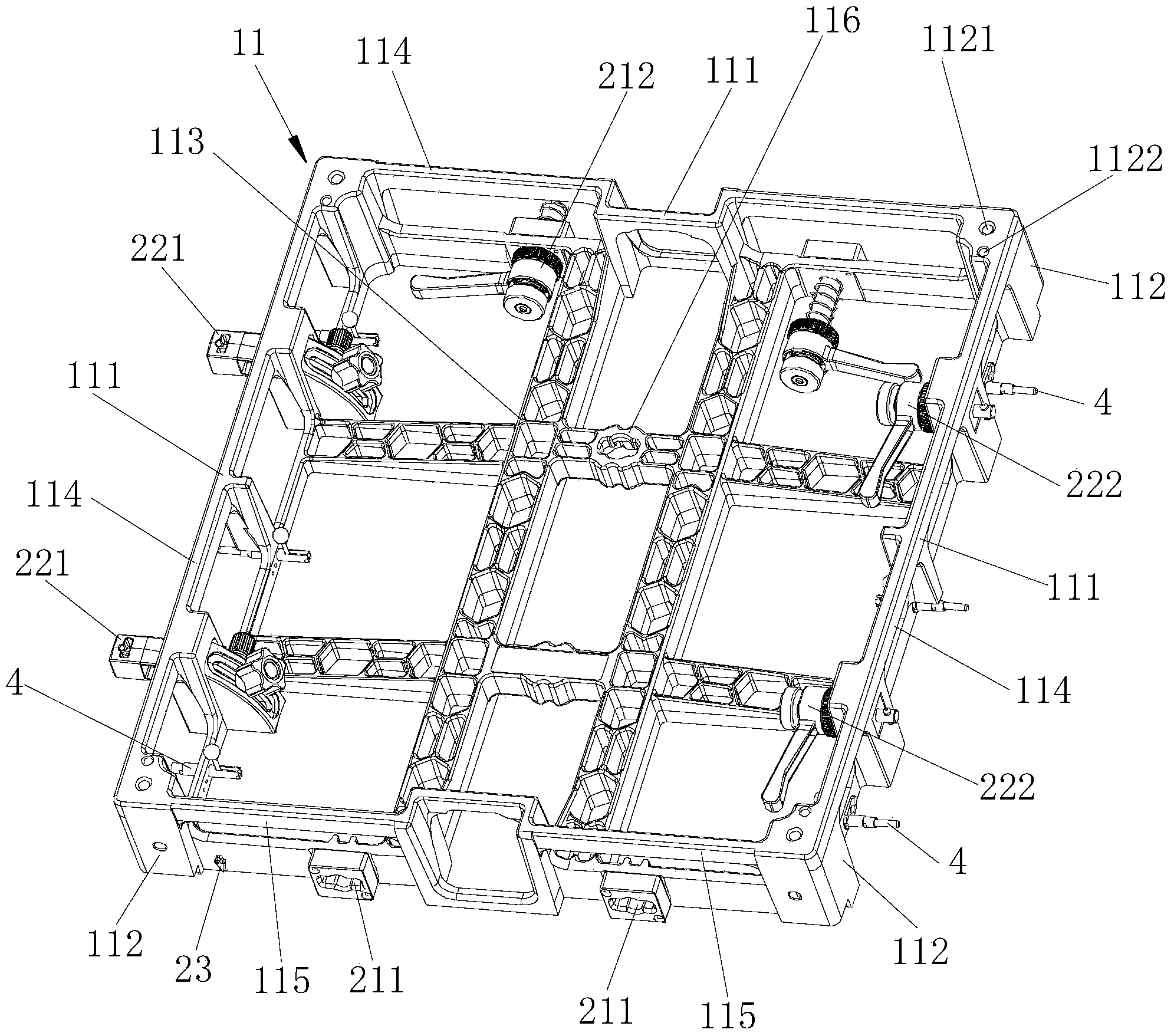

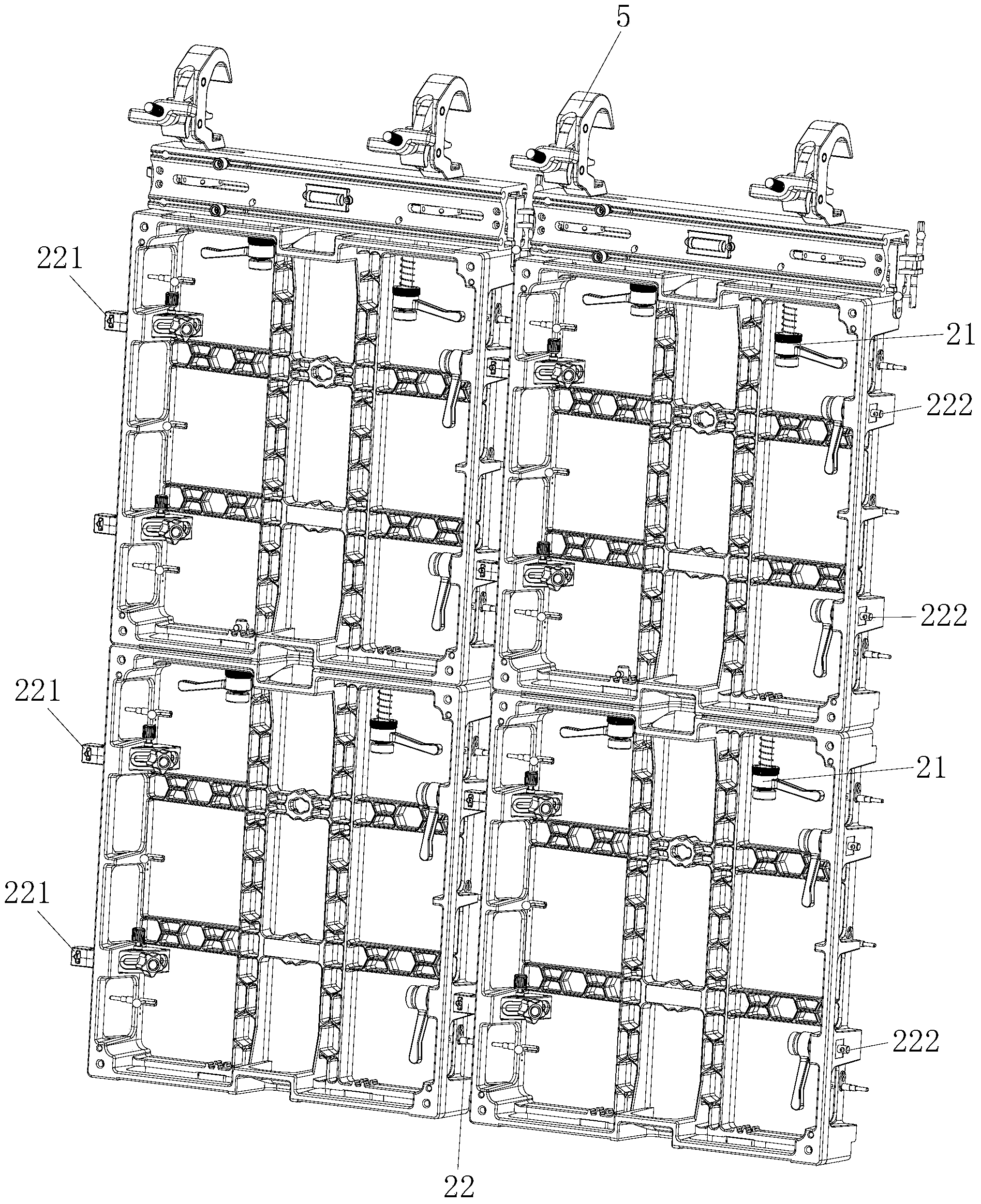

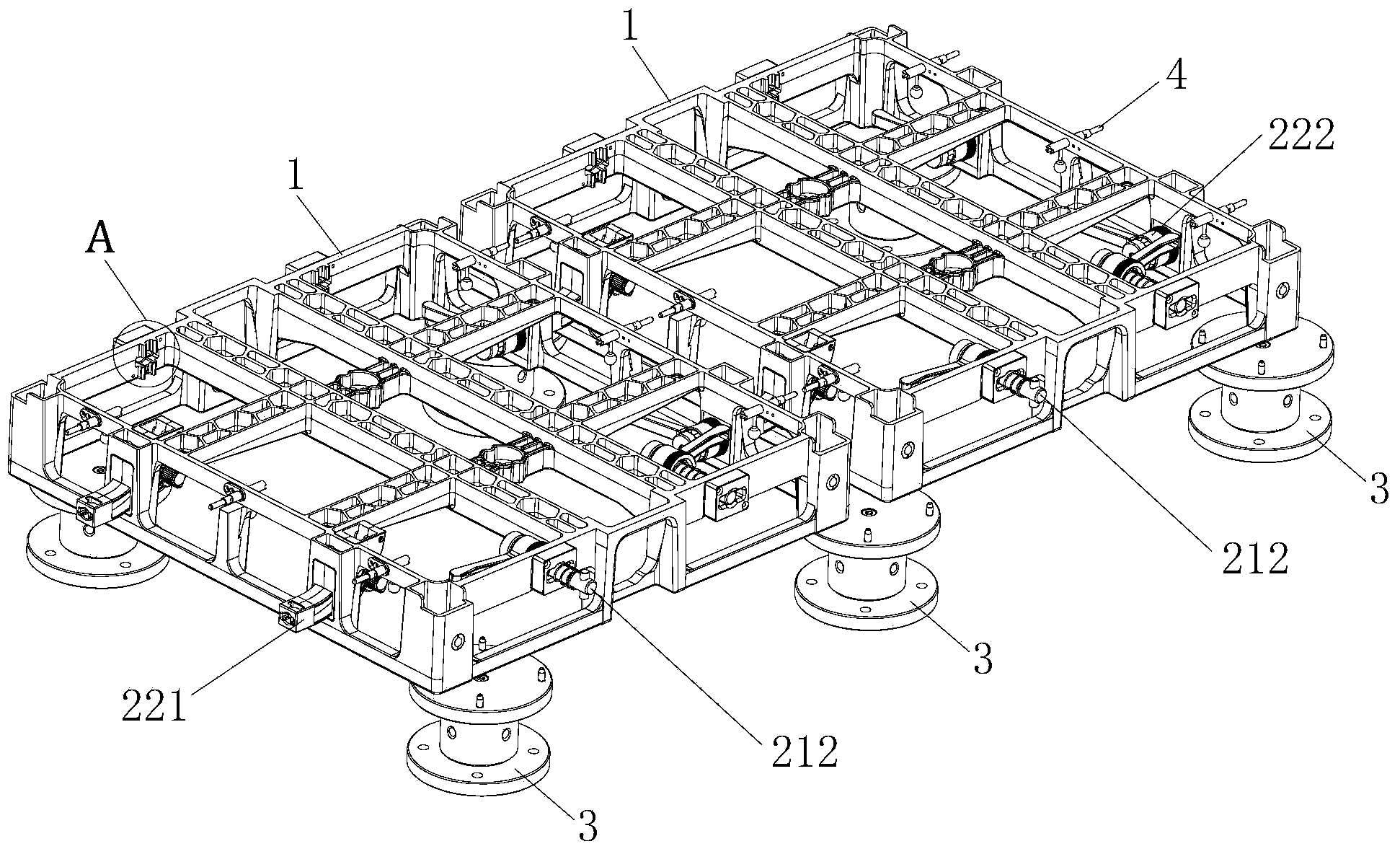

[0024] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a frame 1 for LED display screens. The frame 1 can be applied to vertically installed display screens, or laid on the ground for floor tile display screens, including A hollow main body 11 is formed by connecting a plurality of side plates 111 end to end. According to production requirements, the main body 11 formed by combining side plates 111 can be in the shape of a triangle, rectangle, pentagon or hexagon, etc., so that in subsequent assembly It is convenient to be spliced and fixed with another...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com