Medical device case machining process

A technology of medical equipment and processing technology, applied in the field of processing technology of medical equipment housing, can solve the problems of occupying the outer surface space of the housing and increasing the cost of the housing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

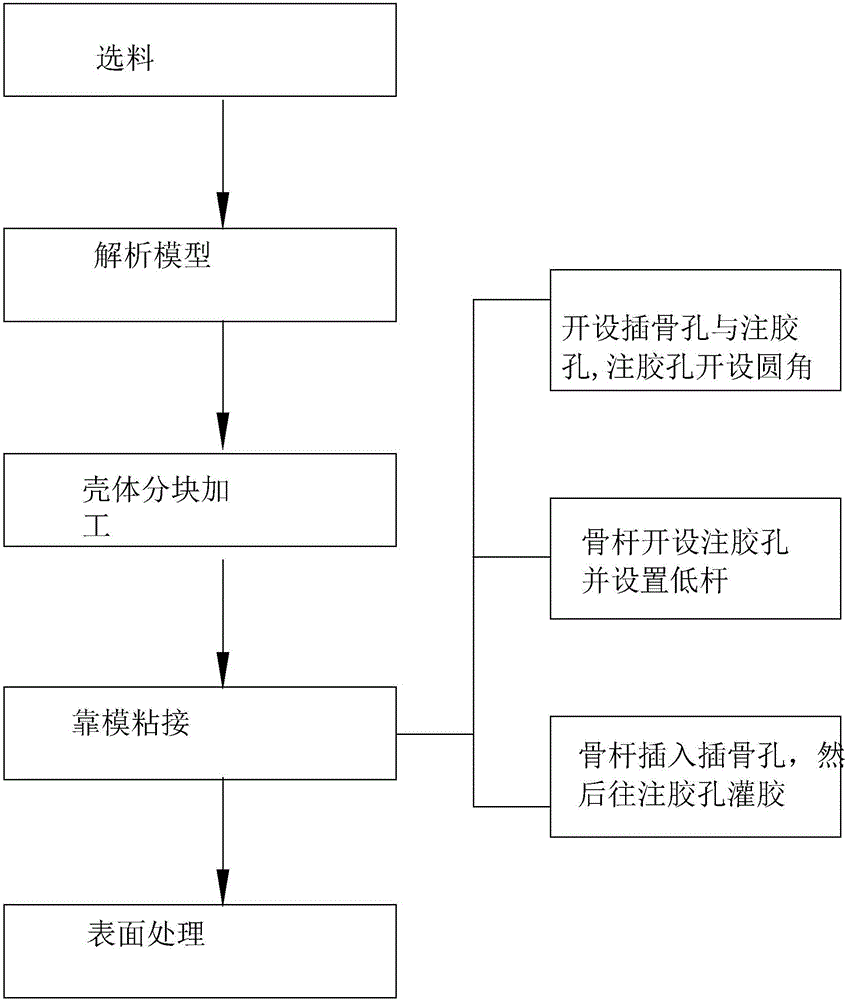

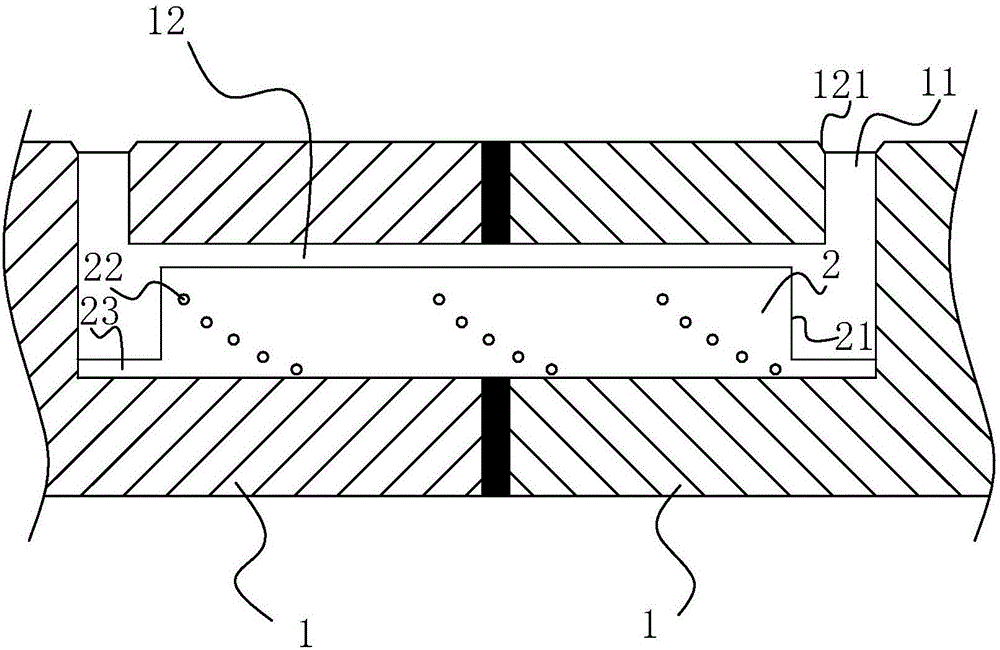

[0040] Embodiment, a kind of processing technology of medical device shell, such as figure 1 and figure 2 shown, including:

[0041] The first step of material selection: select the type of material according to the type of equipment, purpose, and use environment. For example, it is not suitable to use materials with low surface hardness such as ordinary ABS, PVC, and PMMA when there are requirements for wear resistance and scratch resistance. Choose materials with low melting point such as PE and PVC. When there is a requirement for high structural strength, it is easy to choose materials with good mechanical properties such as PC and ABS. When there is a requirement for flame retardancy, it is necessary to use materials with flame retardants. Chemically inert materials such as board and polytetrafluoroethylene;

[0042] Select the shape of the material according to the shape of the equipment, the object of use, etc.; for example, pipe materials should be used directly for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com