Ultra high speed test CRH (China Railway High-Speed) train bogie

An EMU and ultra-high-speed technology, which is applied in the direction of bogies, railway car body parts, and transmission devices driven by electric motors, can solve problems such as poor reliability, harsh welding process requirements, and large local stress, and facilitate batch manufacturing , The effect of dynamic parameter optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

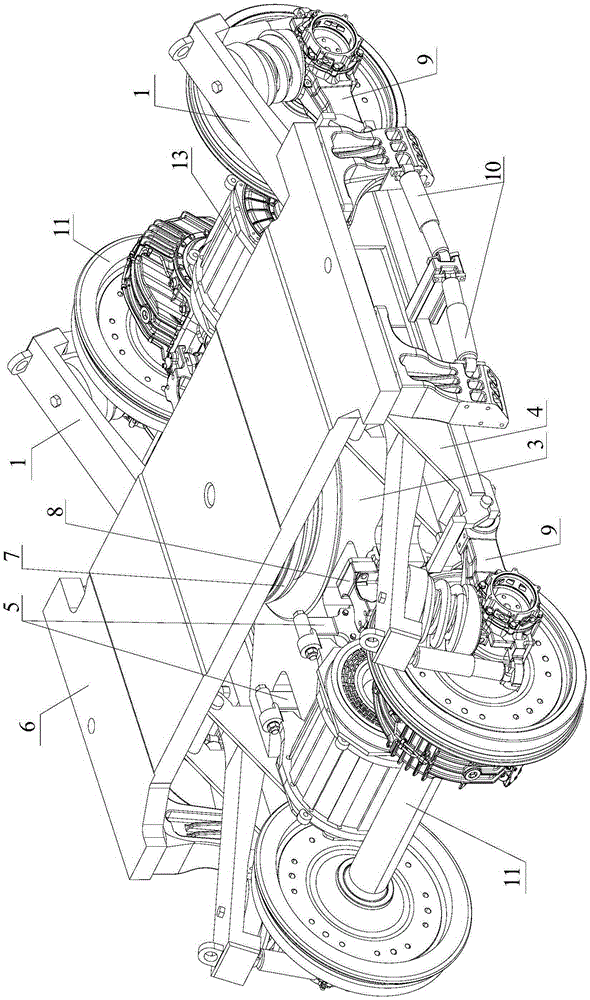

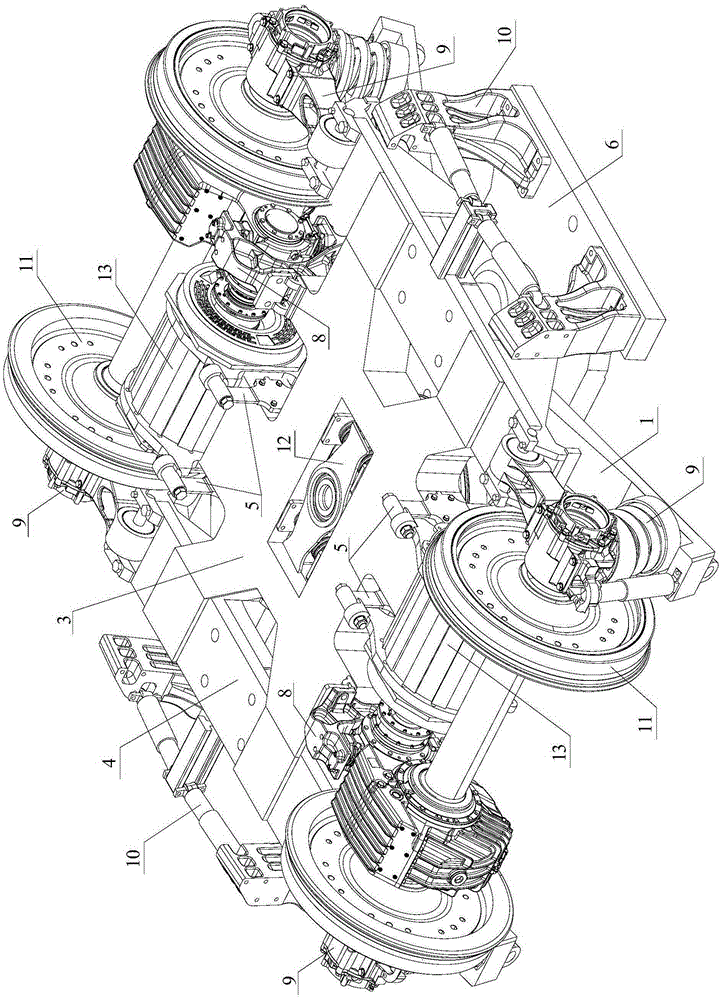

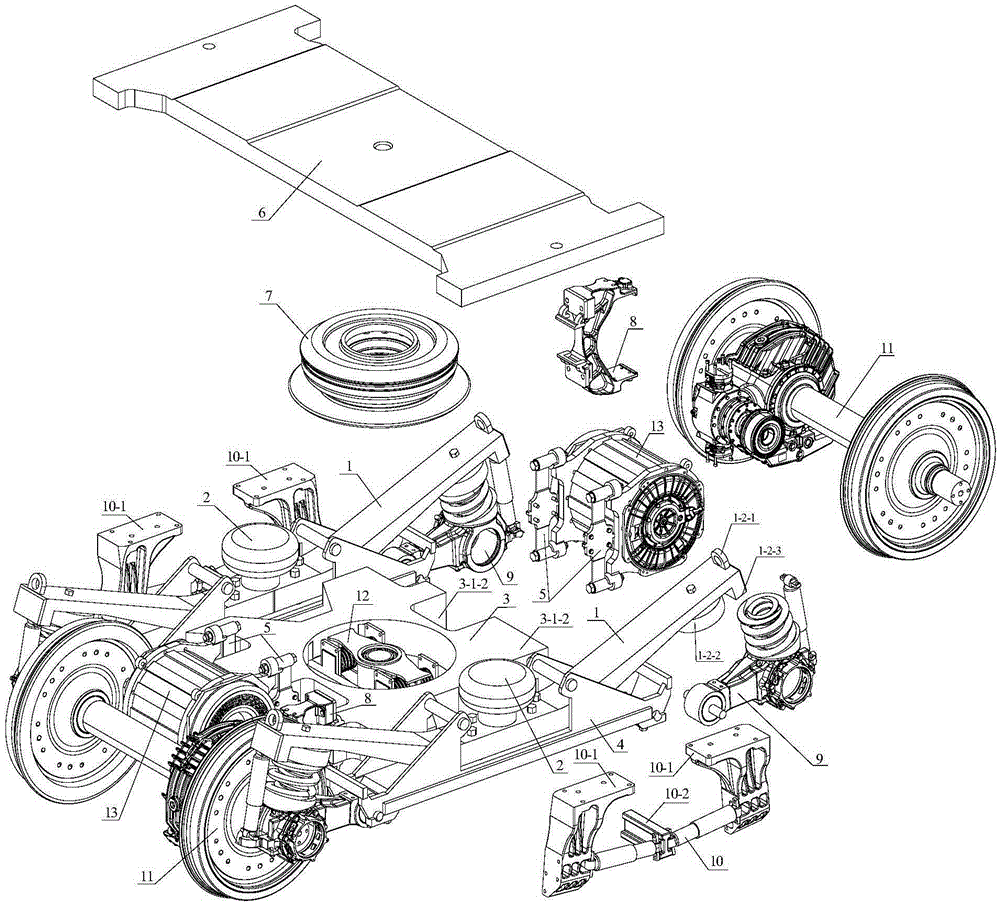

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] like Figure 1 to Figure 16 As shown, the ultra-high-speed test EMU bogie of the present invention includes an elastic frame, two traction motor elastic hanger assemblies 13, two motor suspension devices 5, corbels 6, central air springs 7, gear box supports 8, four A series of positioning devices 9, two anti-serpentine shock absorber devices 10, two wheel set devices 11 and a central traction device 12, said one motor is fixedly connected in the longitudinal direction of the elastic frame through a corresponding motor suspension device 5 respectively On the end face of the side wall, a gear box bracket 8 is fixed on the same longitudinal side wall end face of the aforementioned elastic frame in parallel with the aforementioned motor suspension device 5 . The other motor is fixedly connected in a rotationally symmetric manner with a rotation of 180 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com