Elastic frame of super high speed EMU bogie

An EMU and ultra-high-speed technology, which is applied to bogies, devices that move laterally between the chassis and bogies, and railway car body parts, etc., can solve the problems of demanding welding processes, inconvenient maintenance, and long production cycles. problems, achieve the effect of reducing the weight of the frame, improving the yield, and reducing the total number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

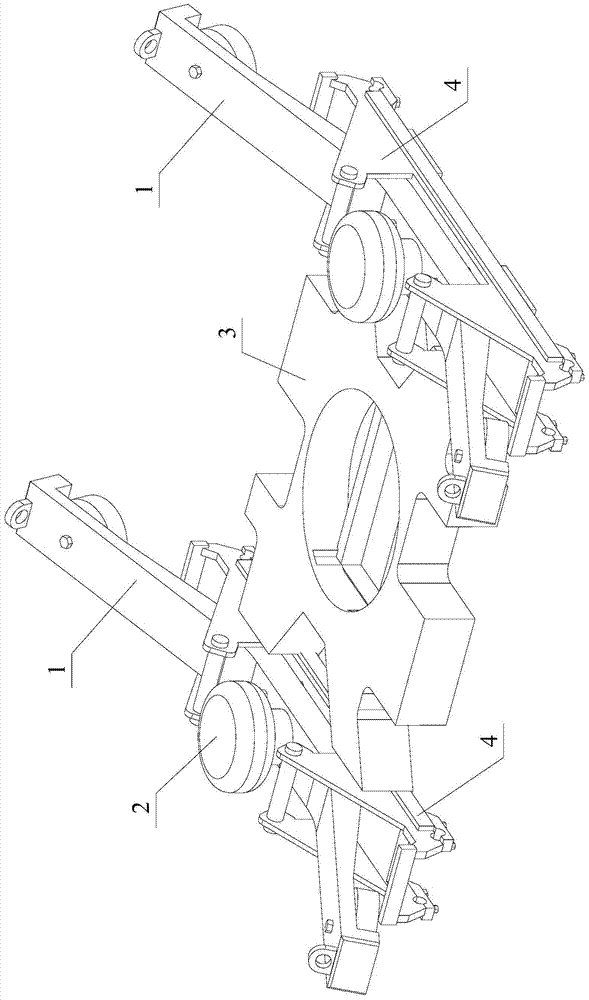

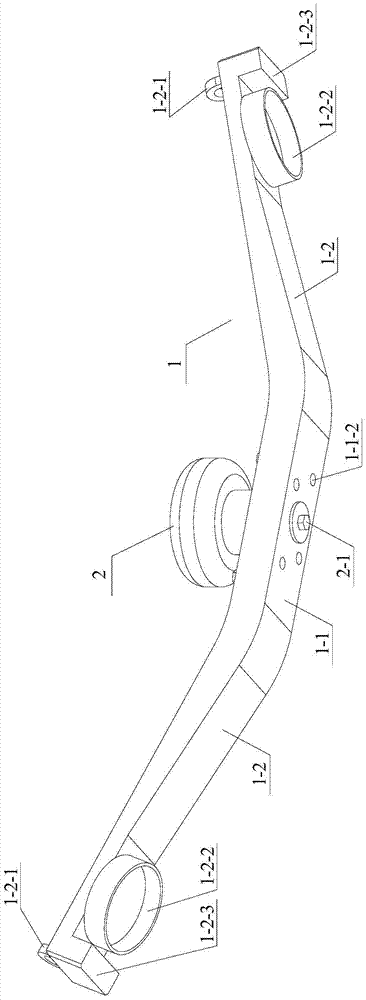

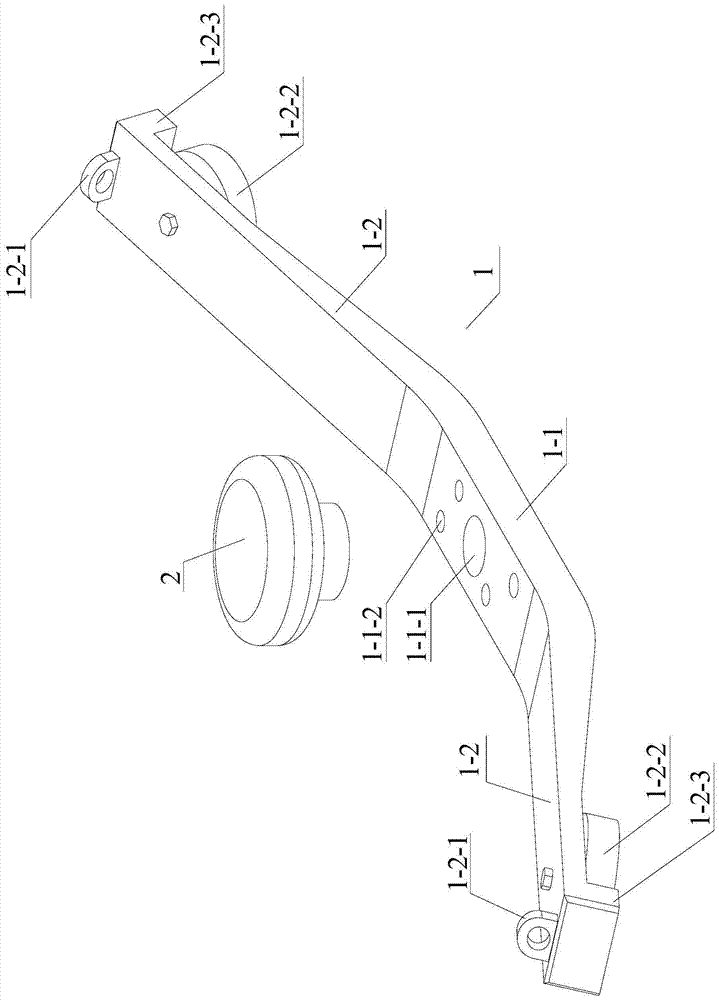

[0023] Such as Figure 1 to Figure 7 As shown, the elastic framework of the super high-speed EMU bogie of the present invention includes two elastic side beams 1, two secondary auxiliary sleeper springs 2, a horizontal and longitudinal beam integrated tray frame 3 and two side beam mounting seats 4, horizontal and vertical The beam integrated tray frame 3 includes a well-shaped frame main body 3-1 and two side beam mounting seat trays 3-2. The well-shaped frame main body 3-1 is welded by upper and lower two well-shaped steel plates and multiple side plates. The overall box-shaped structure formed has a motor suspension mount 3-1-2 and a gear box mount 3-1-3 respectively on its longitudinal upper and lower ends. The central traction seat through hole 3-1-1 is fixedly connected with a rectangular central traction device mounting bracket. The middle part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com