Backlight module with narrow frame of liquid crystal display device

A technology for liquid crystal display devices and backlight modules, which is applied to components of lighting devices, lighting devices, fixed lighting devices, etc., and can solve problems such as occupying space on the backplane, unable to lock the front panel of the frame with screws, and having no space for nuts, etc. , to achieve the effect of ensuring structural strength, narrowing the border, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

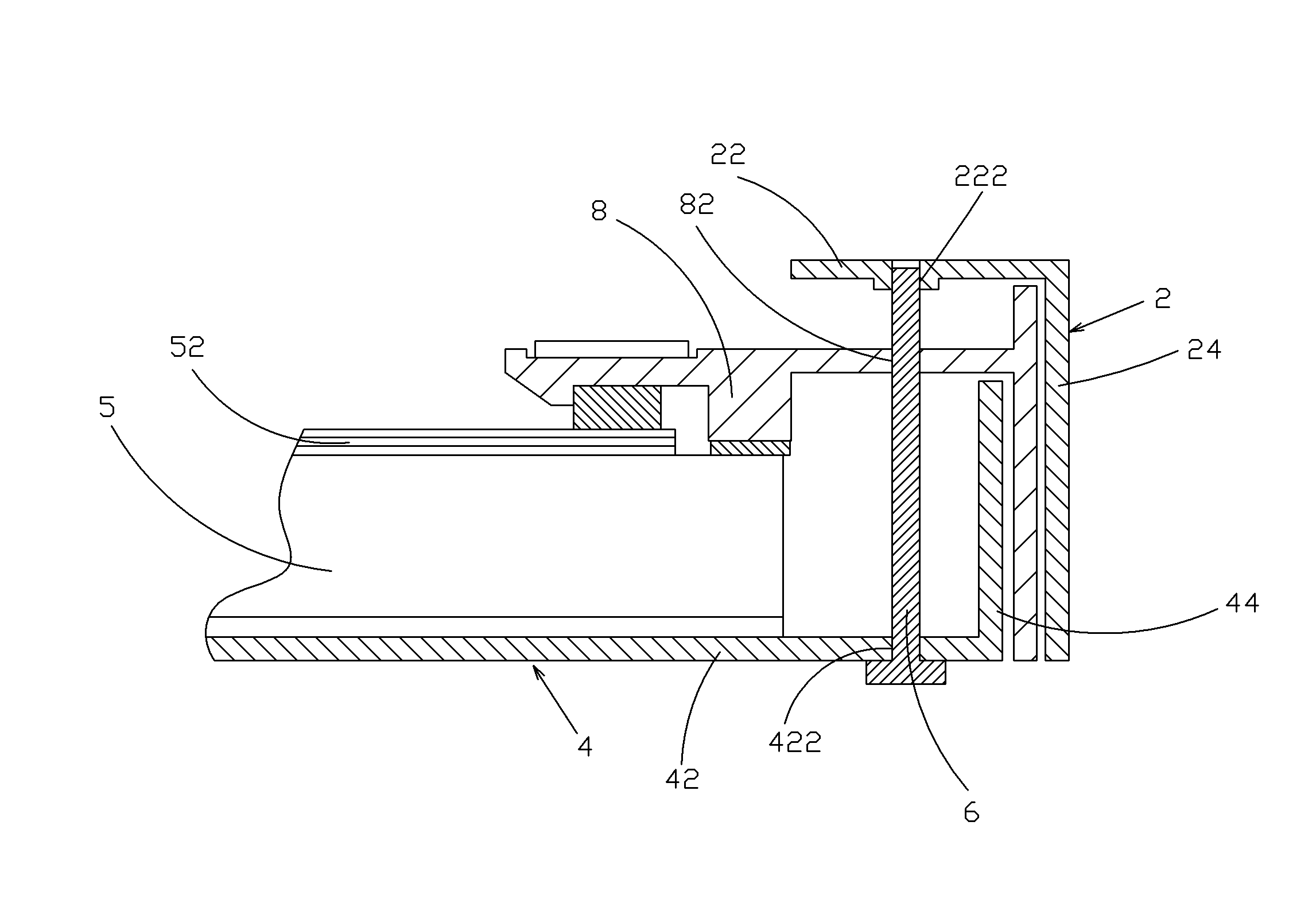

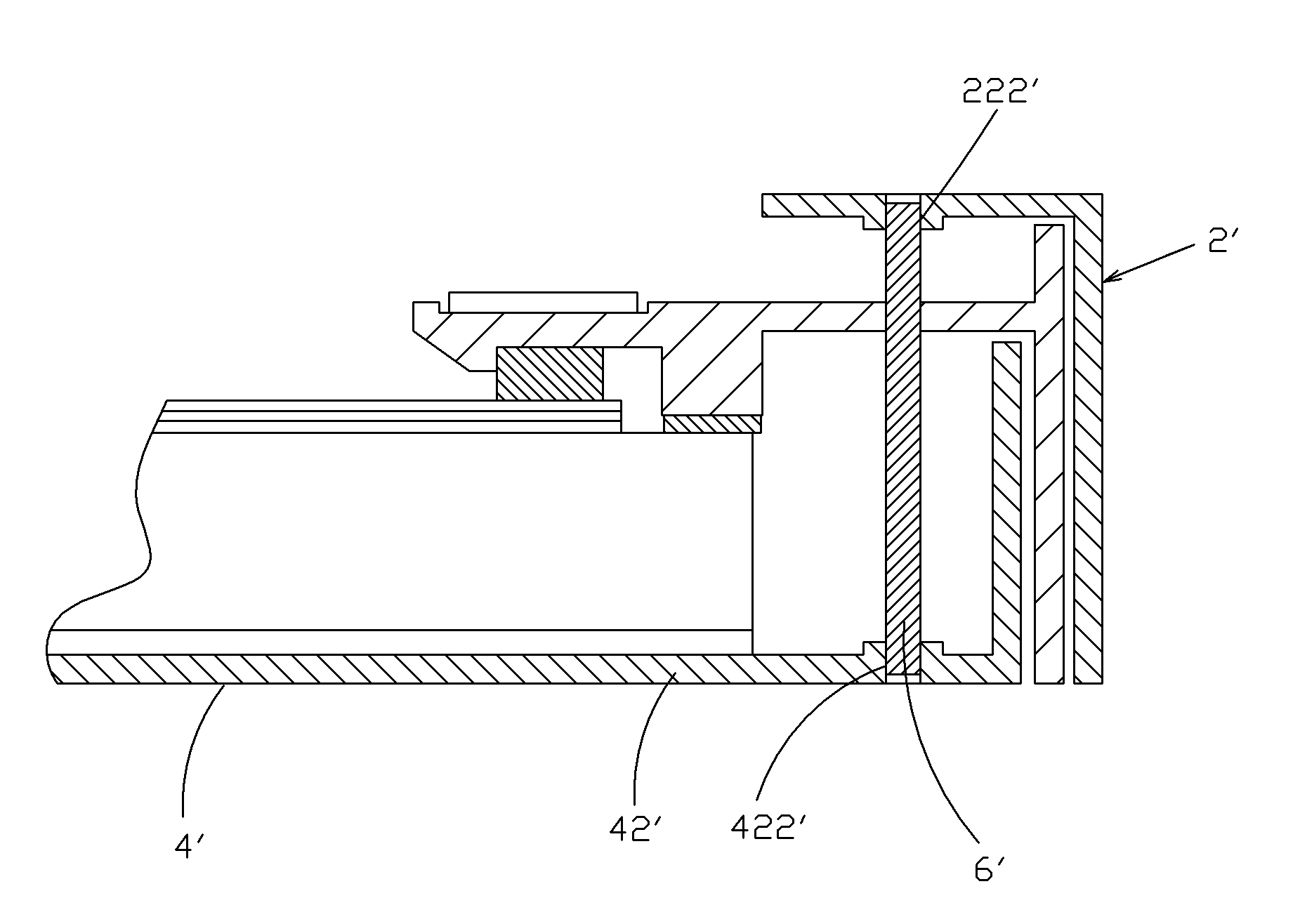

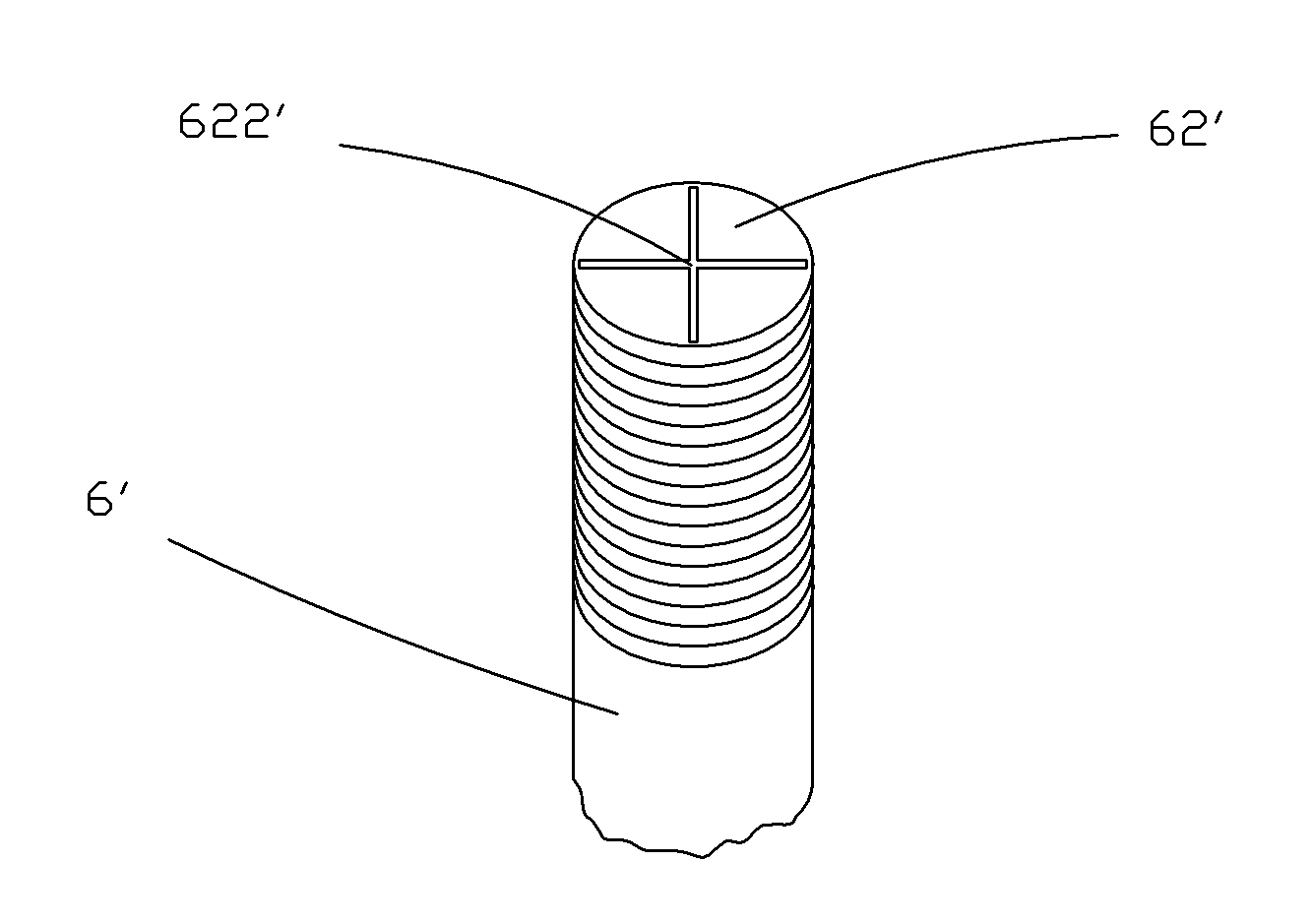

[0019] like figure 1 As shown, it is the first embodiment of the narrow frame backlight module of the liquid crystal display device of the present invention, which includes: a frame (bezel) 2, a back plate 4, a light guide plate 5 arranged on the back plate 4, and a light guide plate arranged on the back plate 4. The optical film 52 on the light board 5 , the connecting piece 6 , and the plastic frame 8 arranged on the backplane 4 , the connecting piece 6 locks the frame 2 and the front panel of the backplane 4 .

[0020] The frame 2 includes a front panel 22 forming a display opening, and a side panel 24 extending downward from one end of the front panel. The front panel 22 is concavely formed with a first tooth extraction hole 222 with an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com