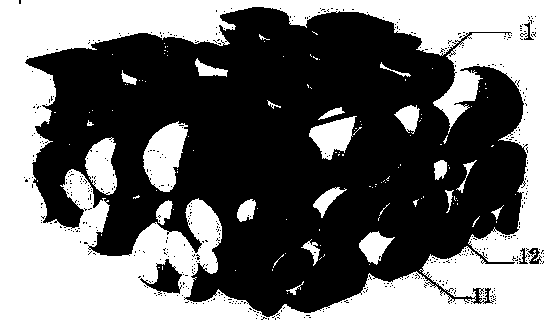

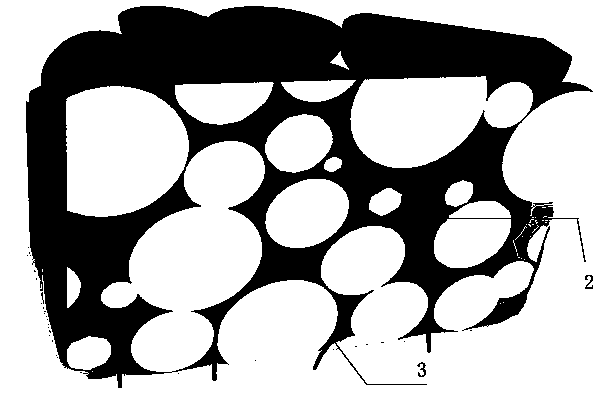

Micro-particle sound-absorbing board and preparation method thereof

A technology of sound-absorbing panels and particles, which is applied in the direction of sound-generating devices, ceramic products, and other household appliances. It can solve the problems of unpredictable porosity, increase the amount of binder, and high cost, achieve excellent sound-absorbing performance, and improve absorption. Acoustic effect, the effect of promoting the consumption of sound energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

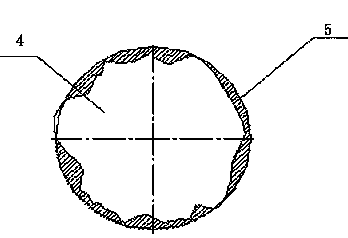

[0058] 1. Selection of raw materials: Select the aeolian sand grains with an angular shape coefficient less than 1.5, and use 20-mesh and 25-mesh sieves to screen out particles with a diameter of 0.8mm; use 90-mesh and 100-mesh sieves to screen out particles with a diameter of 0.15mm.

[0059] 2. Mixing of raw materials: Take 90kg of φ0.8mm particles and 10kg of φ0.15mm particles and mix evenly.

[0060] 3. Covering binder: Put the above mixed raw materials into a sealing device, start the vacuum cleaner connected to the top of the sealing device, remove the mud and dust in the raw materials and then close it; then enter the compressed air at the bottom of the sealing device to stir the raw materials to suspend, Simultaneously spray 3kg of adhesive epoxy resin into mist form, control the injection speed of adhesive to 20mg / s, after spraying, take out and dry in the shade under normal temperature to be coated particles. After testing, the angle coefficient of the film-coated pa...

Embodiment 2

[0064] 1. Selection of raw materials: Select ceramsite with an angle coefficient less than 1.5, use 20 mesh and 25 mesh screens to screen out particles with a diameter of 0.8mm; use 90 mesh and 100 mesh screens to screen out particles with a diameter of 0.15mm.

[0065] 2. Mixing of raw materials: Take 90kg of φ0.8mm particles and 10kg of φ0.15mm particles and mix evenly.

[0066] 3. Covering binder: Put the above mixed raw materials into a sealing device, start the vacuum cleaner connected to the top of the sealing device, remove the mud and dust in the raw materials and then close it; then enter the compressed air at the bottom of the sealing device to stir the raw materials to suspend, At the same time, 5 kg of binder phenolic resin is sprayed into the mist, and the injection speed of the binder is controlled to be 40 mg / s. After spraying, take out and dry in the shade at room temperature to form coated particles. After testing, the angle coefficient of the film-coated part...

Embodiment 3

[0070] 1. Raw material selection: choose the particles after crushing recycled construction waste, whose angle coefficient is less than 1.5, and use 20 mesh and 25 mesh screens to screen out particles with a diameter of 0.8-1mm; use 90 mesh and 100 mesh screens to screen out particles with a diameter of 0.15mm of particles.

[0071] 2. Mixing of raw materials: Take 90kg of φ0.8-1mm particles and 10kg of φ0.15mm particles and mix evenly.

[0072] 3. Covering binder: Put the above mixed raw materials into a sealing device, start the vacuum cleaner connected to the top of the sealing device, remove the mud and dust in the raw materials and then close it; then enter the compressed air at the bottom of the sealing device to stir the raw materials to suspend, At the same time, 10kg of binder urea-formaldehyde resin and furfuryl alcohol resin are sprayed in mist form, and the injection speed of binder is controlled to be 30mg / s. After spraying, take out and dry in the shade at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com