Bidirectional safe pliers for elevator

A technology of safety gear and elevators, which is applied in elevators, transportation and packaging, etc. It can solve the problems of occupied space structure, complexity, and inability to realize two-way braking, so as to achieve the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

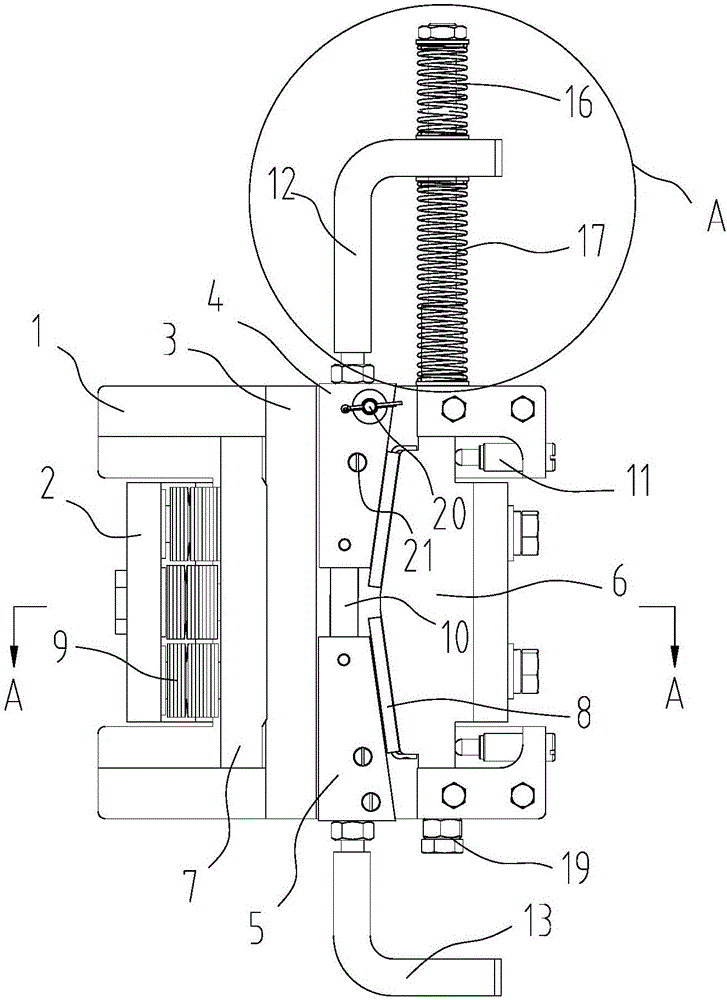

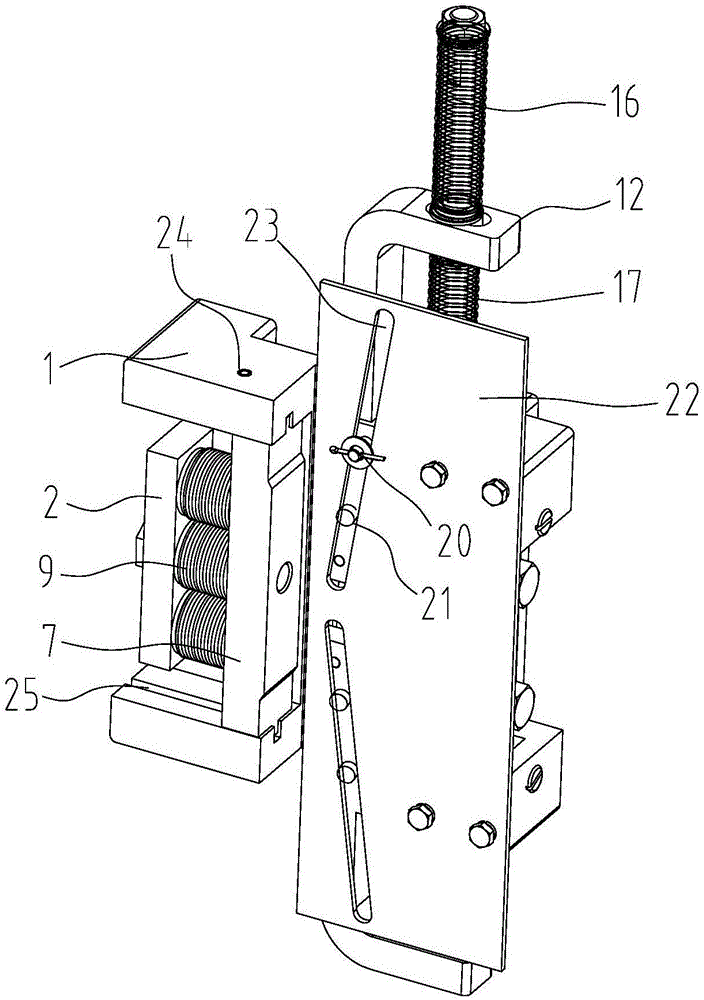

[0037] Such as Figure 1~2 As shown, the two-way safety gear includes a bracket 1, a flat clamp body 7, a wedge clamp body group, a double wedge 6 and a linkage frame 2, Figure 1~2 Shown in is the front of bracket 1. The rail groove 3 is vertically arranged on the front of the support 1 .

[0038] The double wedges 6 and the flat pliers 7 are installed on the bracket 1 and are respectively located on both sides of the guide rail groove 3 . Such as Figure 6 As shown, the upper and lower ends of the front of the bracket 1 are respectively provided with slideways 25, and the double wedges 6 and the flat pliers 7 are slidably inserted into the slideways 25 at both ends. A limit pin 24 is installed on the bracket 1 on the left side of the guide rail groove 3 to limit the sliding position of the flat pliers body 7 .

[0039]The upper and lower ends of the right side of the bracket 1 are respectively provided with elastic parts 11, the fixed end of the elastic part 11 is fixed ...

Embodiment 2

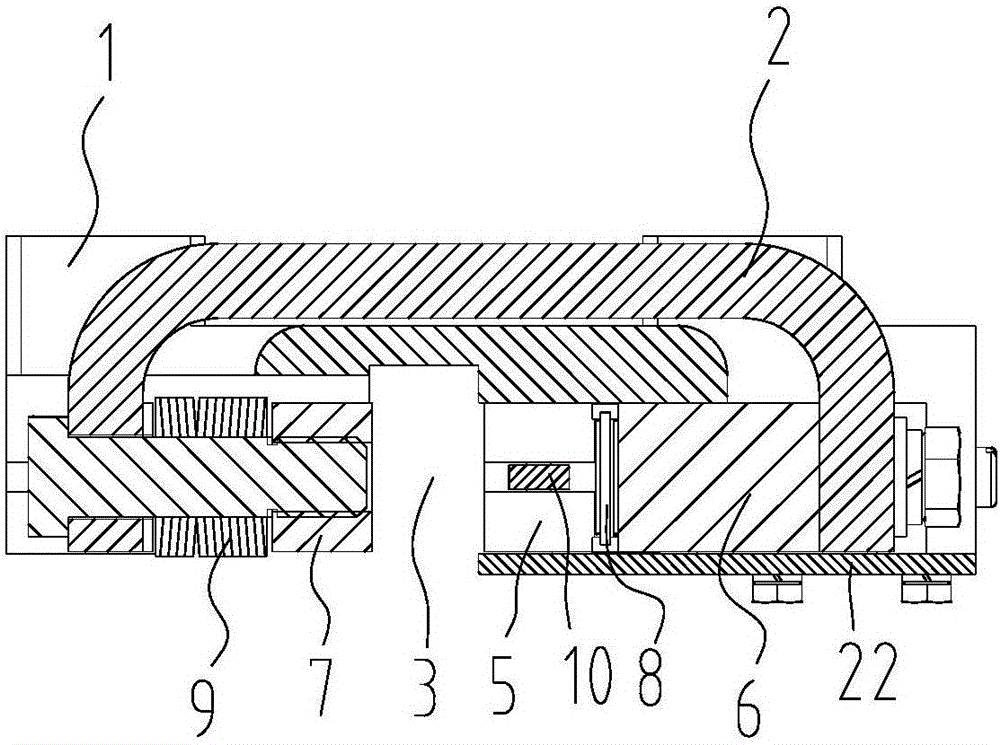

[0056] Such as Figure 7 , Figure 8 As shown, the difference between embodiment 2 and embodiment 1 is that the linkage frame 2 connected with the double wedge 6 and the flat pliers body 7 is a U-shaped leaf spring 2', and the U-shaped leaf spring 2' is close to the flat pliers body Disc spring 9 is not provided between an end of 7 and flat pliers body 7 . Since the U-shaped leaf spring 2' itself is an elastic reset member, when the double wedge 6 squeezes one end of the U-shaped leaf spring 2', the other end will simultaneously squeeze the flat pliers body 7 to generate a braking force to prevent the car from laterally moving. Displacement or rail deformation. Other structures of the two-way safety gear in Embodiment 2 are the same as those in Embodiment 1, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com