Rotating beam preheating laser shock wave micro-texturing machining device and method

A shock wave and micro-modeling technology, used in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of poor micro-modeling processing quality, impact on the surface of micro-cracks, low processing efficiency, etc. Improve and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

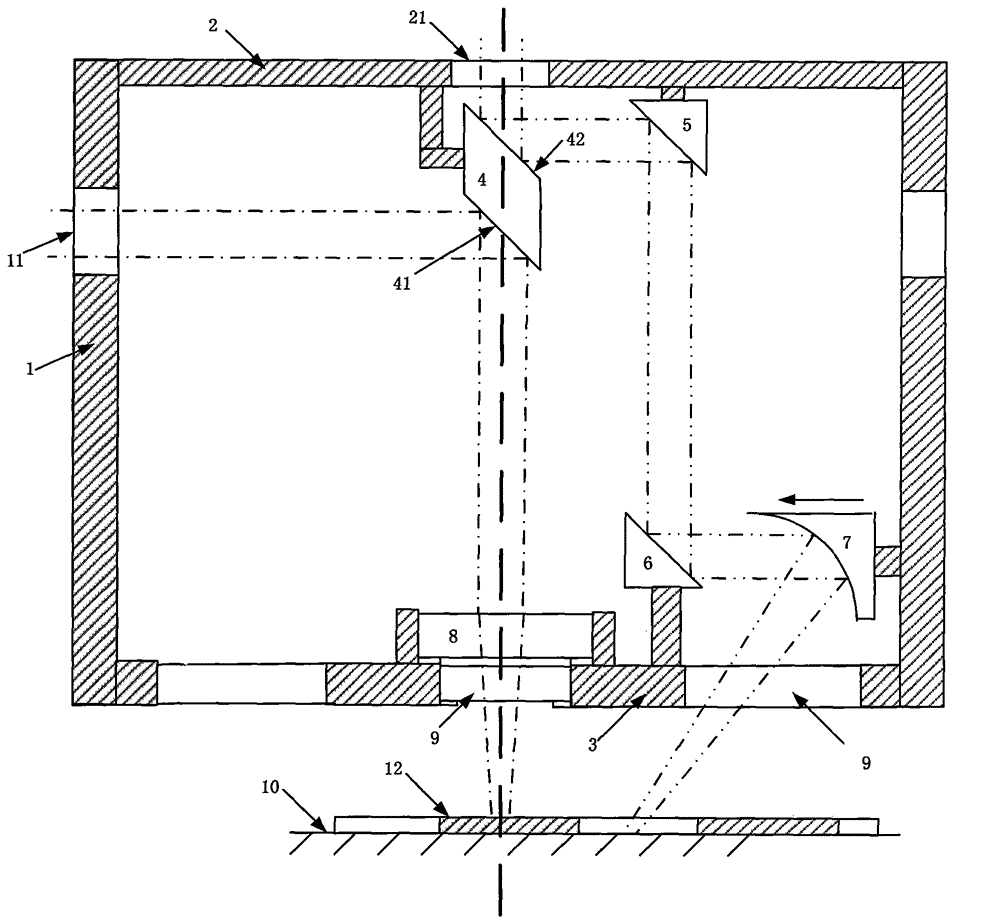

[0034] Such as figure 1 As shown, the present invention provides a laser shock wave micro-machining device for rotating beam preheating, including a first laser for outputting a shock wave laser beam, for outputting a continuous laser beam or a long pulse width (the pulse width is on the order of milliseconds) and above) the second laser of the pulsed laser beam, the composite processing head and the processing head driving mechanism;

[0035] The composite processing head is in the shape of a hollow sleeve, installed on the processing head drive mechanism, and is driven by the processing head drive mechanism to rotate integrally around its own axis (shown by the dotted line in the figure); wherein, the processing head drive mechanism can be driven by the CNC machine tool spindle and other mechanisms, the composite processing head is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com