Synchronization fertilizer apparatus of sowing machine

A fertilization device and seeder technology, which is applied to seeder parts, fertilizers, and seeding equipment, can solve problems such as increasing use costs, reducing farmers' actual income, and difficulty in synchronizing seeding and fertilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

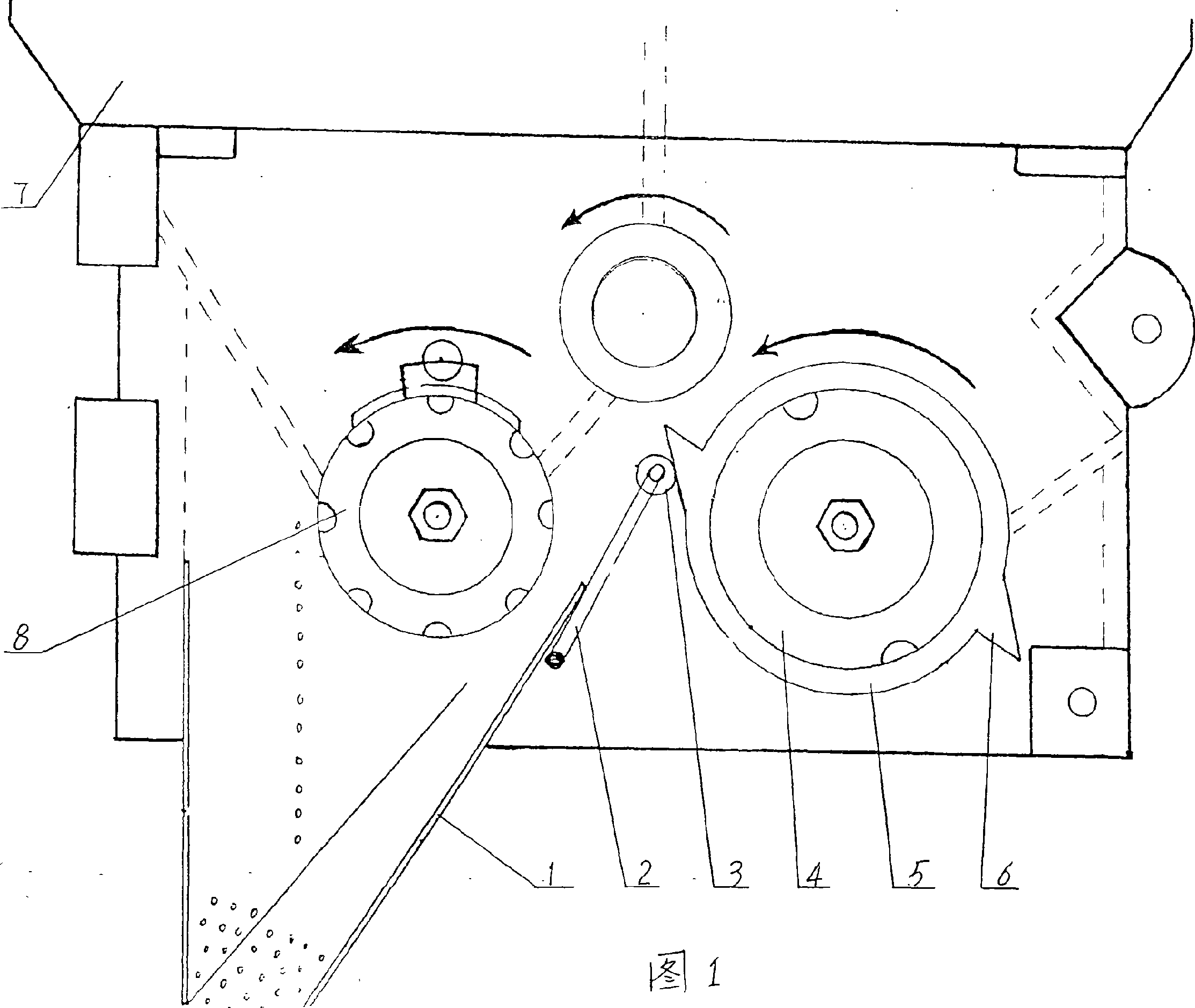

[0011] As shown in Figure 1, a kind of planter synchronous fertilization device, comprises the seed fertilizer case 7 that kind, fertilizer are packed separately, and this kind of fertilizer case bottom installs sowing wheel 4 and fertilizer wheel 8 respectively, and the row of said kind fertilizer case A movable cover 1 is installed below the fat wheel, and a crank shaft 2 for controlling its activities is installed above the movable cover. The crank shaft is connected with a roller 3. Cam 5 is installed, and this cam is provided with a protruding tooth 6 at least, and the number of protruding teeth on this cam is consistent with the number of rows of holes on the sowing wheel, and this protruding tooth is positioned at said roller place and can control roller to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com