Coupling with elastic spider

A technology of elastic coupling and semi-coupling, which is applied in the direction of elastic coupling, coupling, mechanical equipment, etc., can solve the problems of high maintenance cost, insufficient adaptability, complex coupling structure, etc. The effect of prolonging the service life and improving the smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

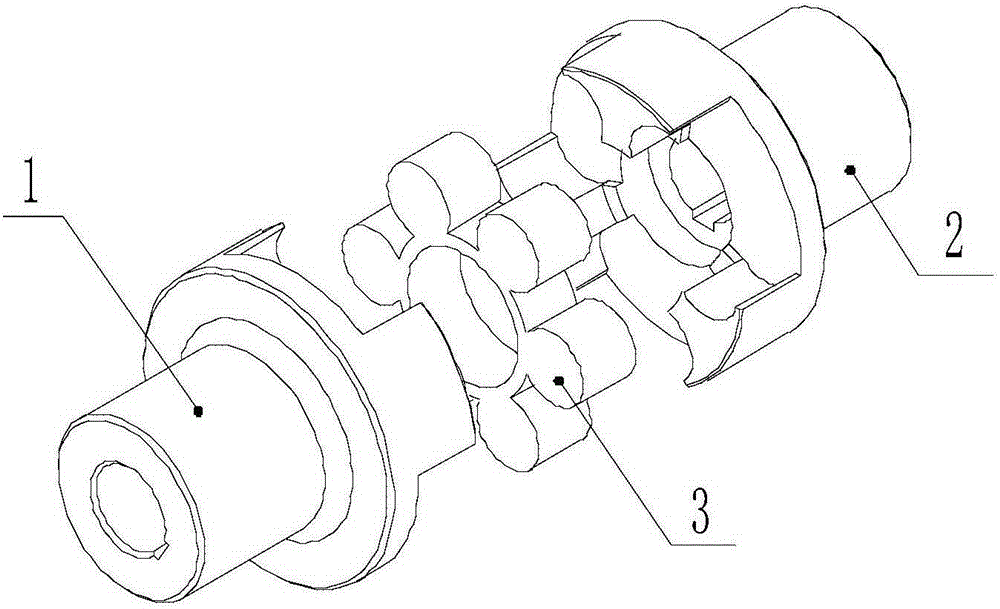

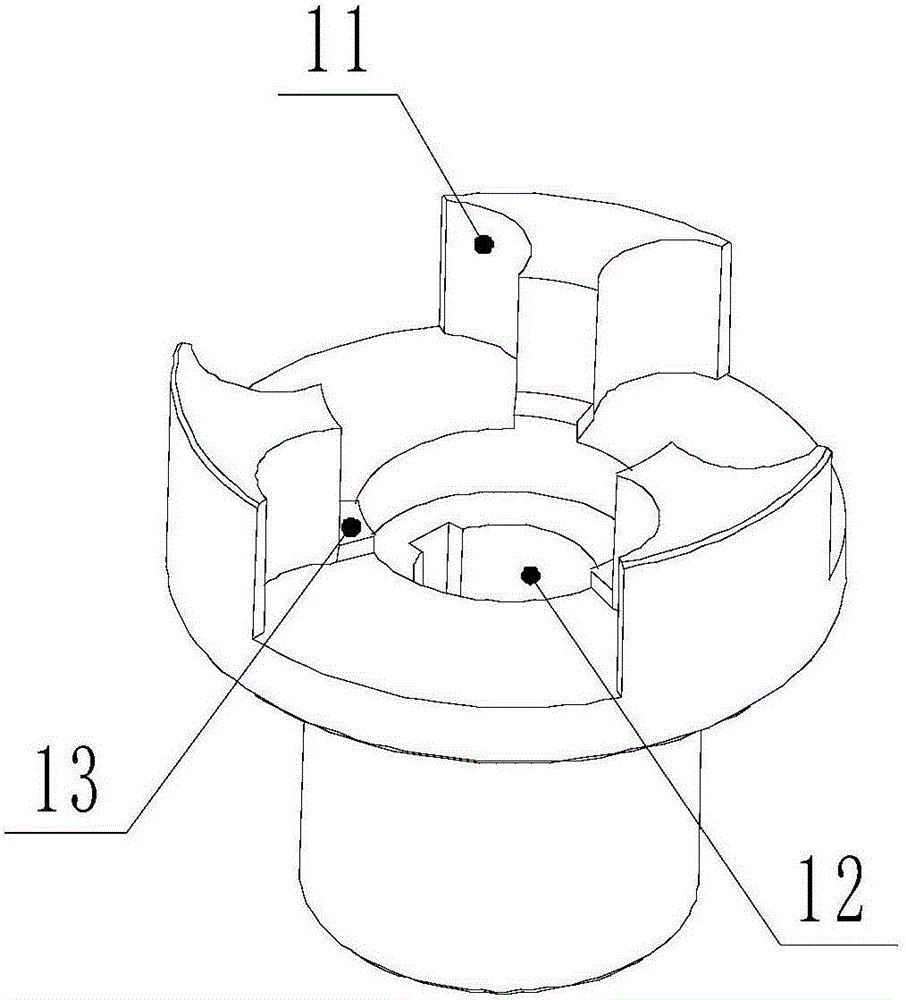

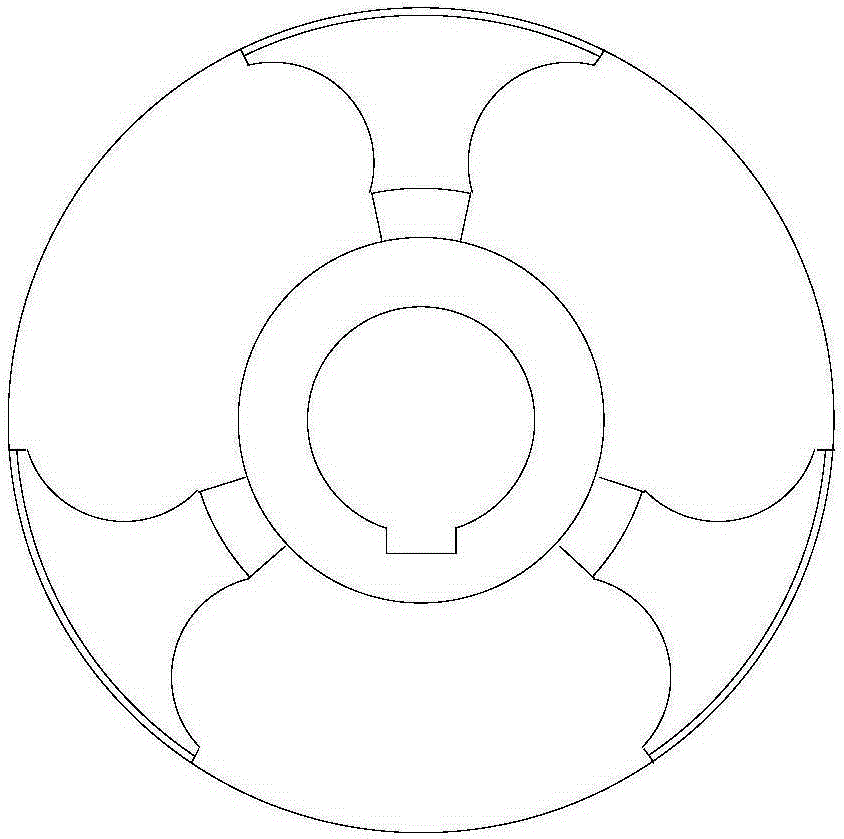

[0017] Examples such as figure 1 , figure 2 and image 3 As shown, a plum-blossom elastic coupling includes a left half-coupling 1, a right half-coupling 2 and a plum-blossom elastic body 3; hole 12, the end faces of the left half-coupling 1 and the right half-coupling 2 are provided with quincunx-shaped protruding teeth 11, and the center position of the quincunx elastic body 3 is provided with a cylindrical hole, and the left half-coupling Bosses 13 are provided on both the device 1 and the right half coupling 2 and are located inside the protruding teeth 11. The two sides of the protruding teeth 11 are concave arc-shaped. Between the half-couplings 2 , the cylindrical boss of the quincunx-shaped elastic body 3 is placed in the gap between the protruding teeth 11 of the left half-coupling 1 and the right half-coupling 2 .

[0018] Preferably, a keyway is processed in the center hole 12 of the left half coupling 1 .

[0019] Preferably, a keyway is processed in the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com