Extruding screw for single screw extruder

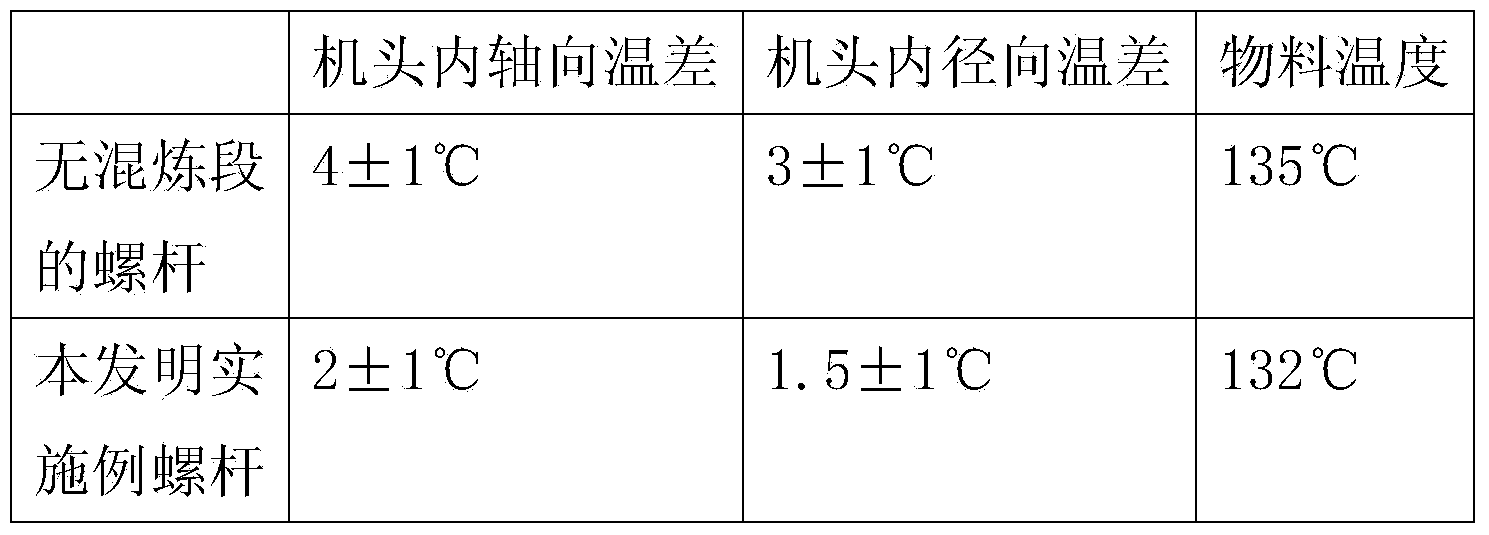

A single-screw extruder and extrusion screw technology, used in the field of extrusion screws, can solve the problems of short service life of parallel twin-screw and conical twin-screw, high equipment wear and high production cost, and achieve lower temperature and equipment. The effect of reduced investment and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

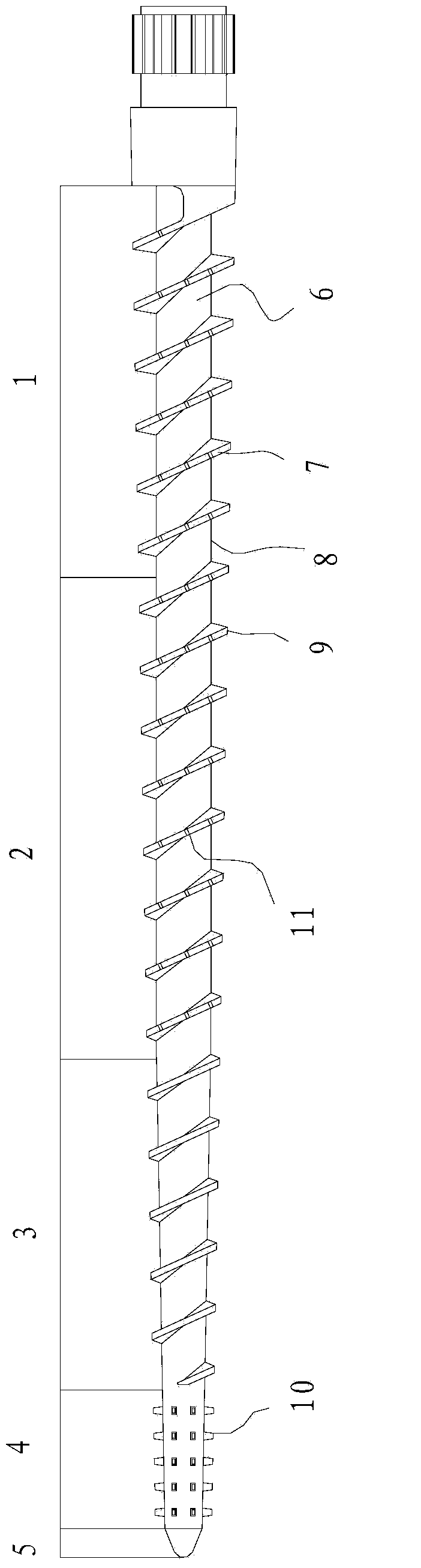

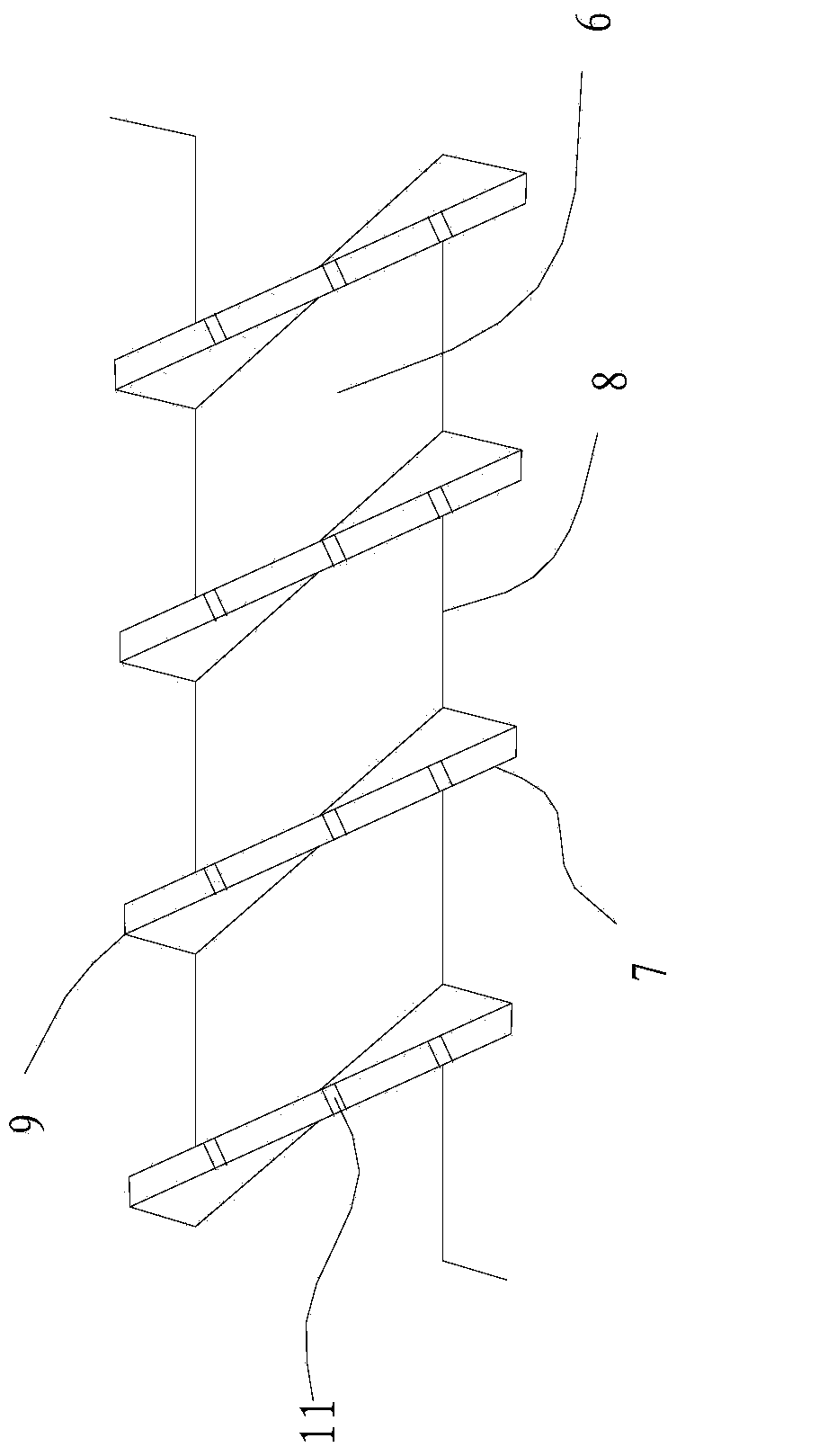

[0014] refer to Figure 1-2 , an extrusion screw of a single-screw extruder, the diameter of the tail of the screw is greater than the diameter of the screw head, and the conical angle between the thread outer diameter 9 line and the screw axis is 0.6-2°, along the direction from the tail to the screw head 5, The feeding section 1, the compression section 2 and the metering section 3 of the single-thread structure and the mixing section 4 with convex teeth 10 on the surface are arranged in sequence, wherein the screw bottom diameter 8 of the feeding section 1 and the screw bottom diameter 8 of the compression section 2 are The same, and parallel to the axis of the screw, respectively, on the thread 7 of the feeding section 1 and the compression section 2, there are several spiral grooves 11 opposite to the thread direction of the feeding section 1, and the bottom diameter of the thread of the metering section 3 8 and the outer diameter of the thread. The diameters 9 are parall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com