Desulfurization catalyst and preparation method thereof

A desulfurization catalyst and production method technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex preparation process of desulfurizer, low desulfurization efficiency, long preparation time, etc., and achieve improvement Boundary conditions, the effect of strengthening the desulfurization process, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

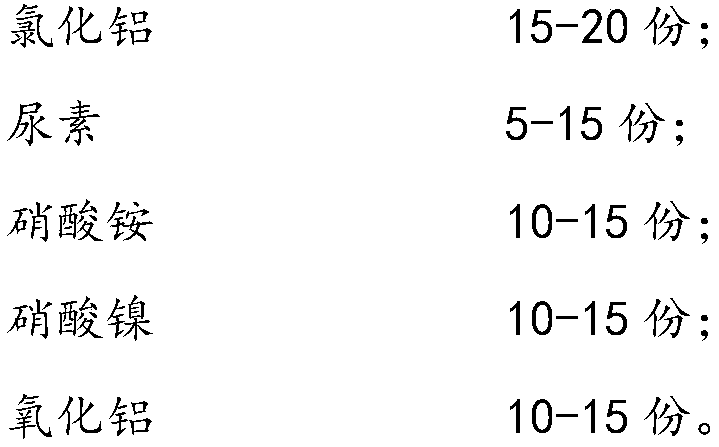

[0028] A desulfurization catalyst comprises, by weight: 15 parts of aluminum chloride, 15 parts of urea, 10 parts of ammonium nitrate, 15 parts of nickel nitrate and 15 parts of aluminum oxide.

[0029] The preparation step of described desulfurization catalyst comprises:

[0030] Step 1: adding specified weight parts of aluminum chloride and urea to the reactor, and adding deionized water for stirring to obtain a mixed solution;

[0031] Step 2: adding ammonium nitrate, nickel nitrate and aluminum oxide to the mixed solution in step 1 and stirring, after stirring evenly, drying the mixture to obtain desulfurization catalyst A.

Embodiment 2

[0033] A desulfurization catalyst comprises, in parts by weight: 20 parts of aluminum chloride, 5 parts of urea, 15 parts of ammonium nitrate, 10 parts of nickel nitrate and 10 parts of aluminum oxide.

[0034] The preparation step of described desulfurization catalyst comprises:

[0035] Step 1: adding specified weight parts of aluminum chloride and urea to the reactor, and adding deionized water for stirring to obtain a mixed solution;

[0036] Step 2: adding ammonium nitrate, nickel nitrate and aluminum oxide to the mixed solution in step 1 and stirring, after stirring evenly, drying the mixture to obtain desulfurization catalyst B.

Embodiment 3

[0038] A desulfurization catalyst comprises, in parts by weight: 18 parts of aluminum chloride, 12 parts of urea, 12 parts of ammonium nitrate, 13 parts of nickel nitrate and 13 parts of aluminum oxide.

[0039] The preparation step of described desulfurization catalyst comprises:

[0040] Step 1: adding specified weight parts of aluminum chloride and urea to the reactor, and adding deionized water for stirring to obtain a mixed solution;

[0041] Step 2: adding ammonium nitrate, nickel nitrate and aluminum oxide to the mixed solution in step 1 and stirring, after stirring evenly, drying the mixture to obtain desulfurization catalyst C.

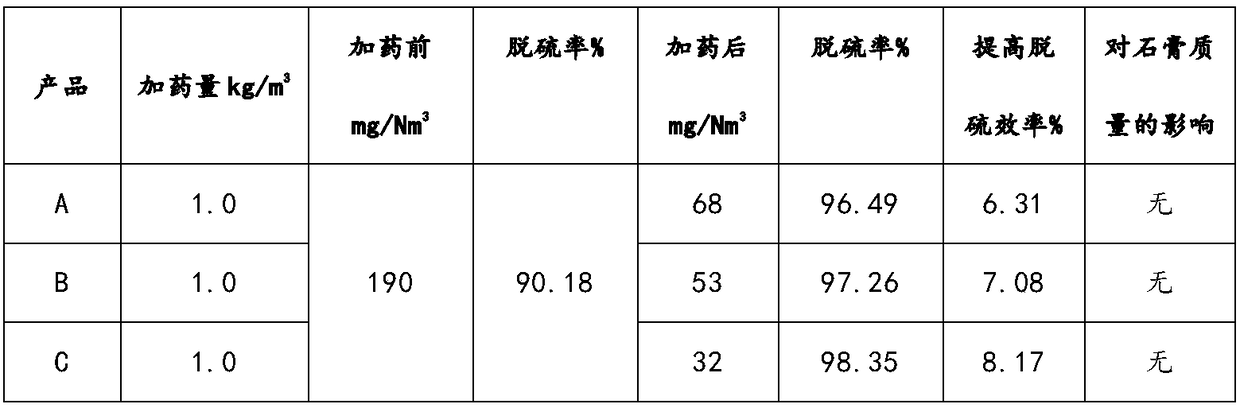

[0042] Use the desulfurizer prepared in the above examples to desulfurize the flue gas, and the desulfurization results are shown in Table 1, wherein, the unit load is 315.5MW, and the original flue gas SO 2 The concentration is 1935mg / Nm 3 .

[0043] Table 1

[0044]

[0045] According to Table 1, it can be concluded that after adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com