Wet motor pump

A motor pump, wet technology, applied in the field of wet motor pump, can solve the problems of low strength, insufficient mechanical vibration, high noise, etc., and achieve the effect of good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

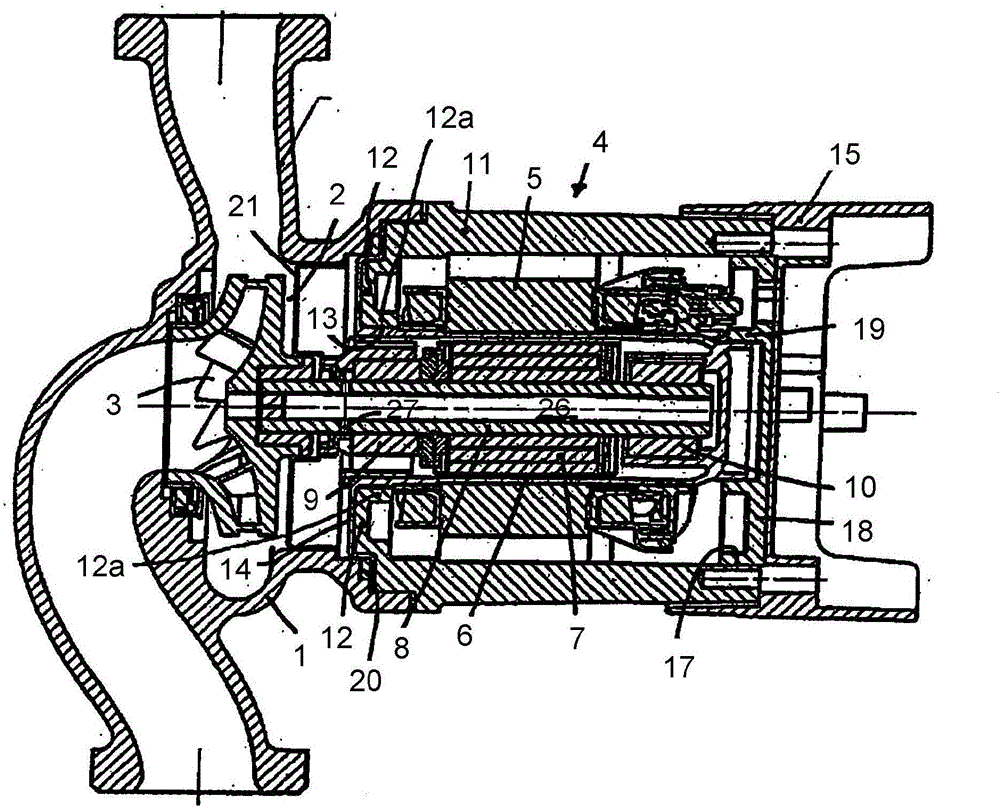

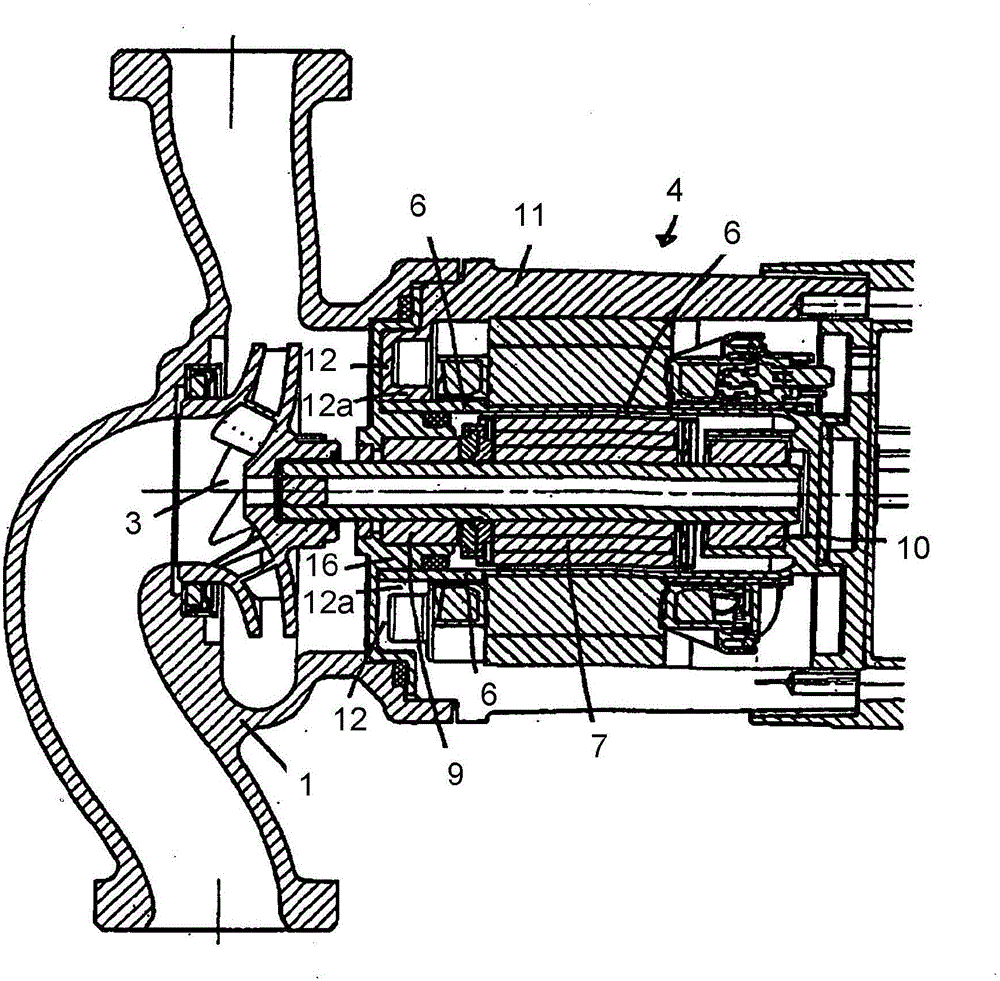

[0020] On the hydraulic side, the wet motor pump has a pump housing 1 which encloses a pump chamber 2 in which a pump impeller 3 runs. Coaxially fastened to the pump housing is a motor housing 4 which encloses a stator 5 in which a sealing pot 6 (or sealing tube) is attached which forms a rotor chamber in which the motor rotor 7 is located. running in the rotor chamber. The rotor 7 has a coaxial shaft 8 which is guided through two bearings 9 , 10 arranged inside the seal pot 6 and which carries the pump impeller 3 at one end.

[0021] On the outer wall 11 of the motor housing 4 , on the hydraulic system side, an inwardly directed annular motor housing flange 12 is integrally formed, on the inner end of which a ring-shaped extension is integrally formed. 12a, the free end of this extension is directed towards the stator 5 . The annular widening 12 a forms a coaxial central opening 13 which surrounds the sealing pot 6 on the outside in such a way that the annular widening rest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com