Method and device for operating an internal combustion engine with exhaust gas recirculation

A technology for exhaust gas recirculation and internal combustion engines, which is applied in the direction of exhaust gas recirculation, internal combustion piston engines, combustion engines, etc., and can solve problems such as torque power reduction, fuel injection torque increase process slowdown, and harmful emission deterioration. , to achieve the effect of improving the formation of boost pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

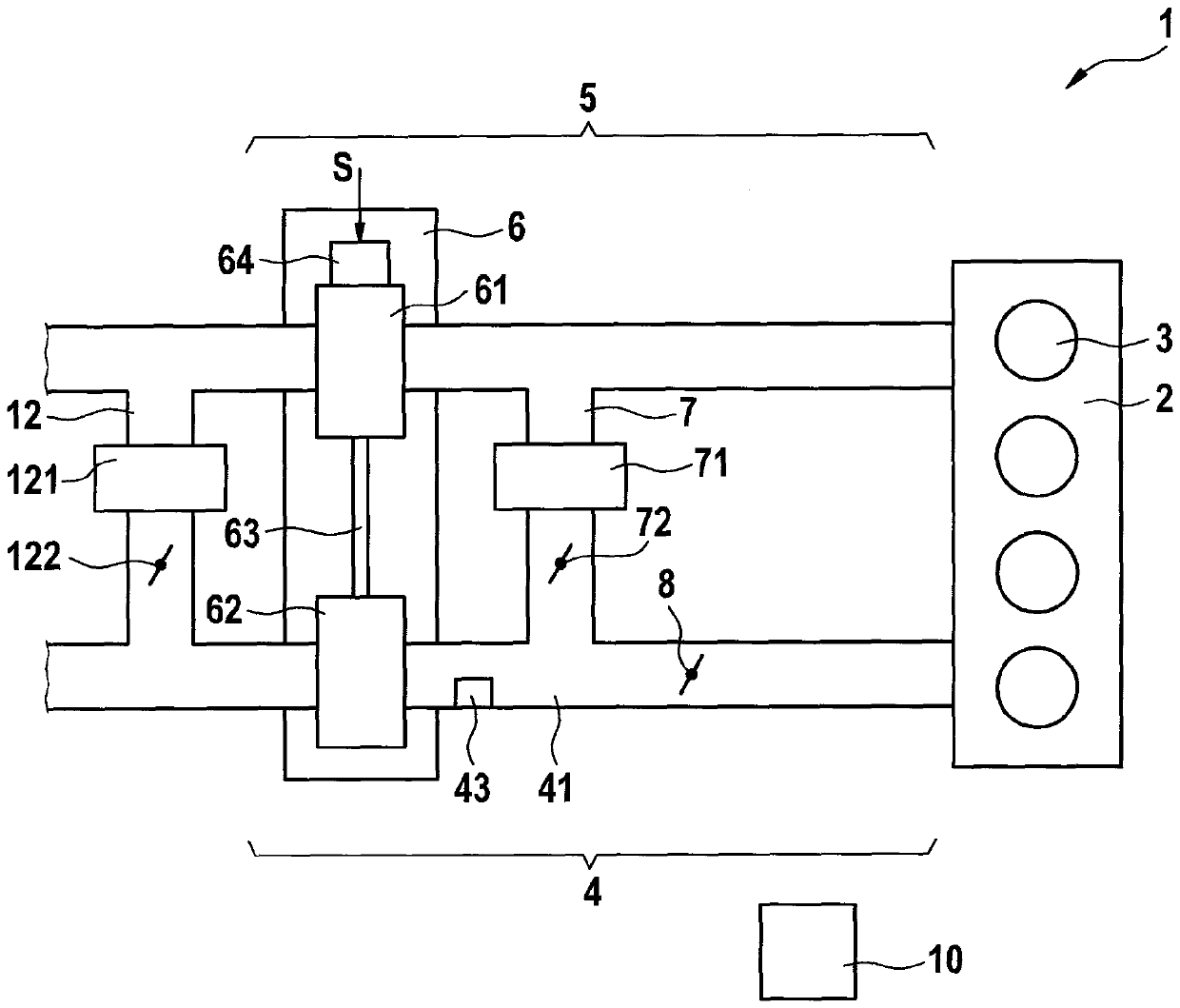

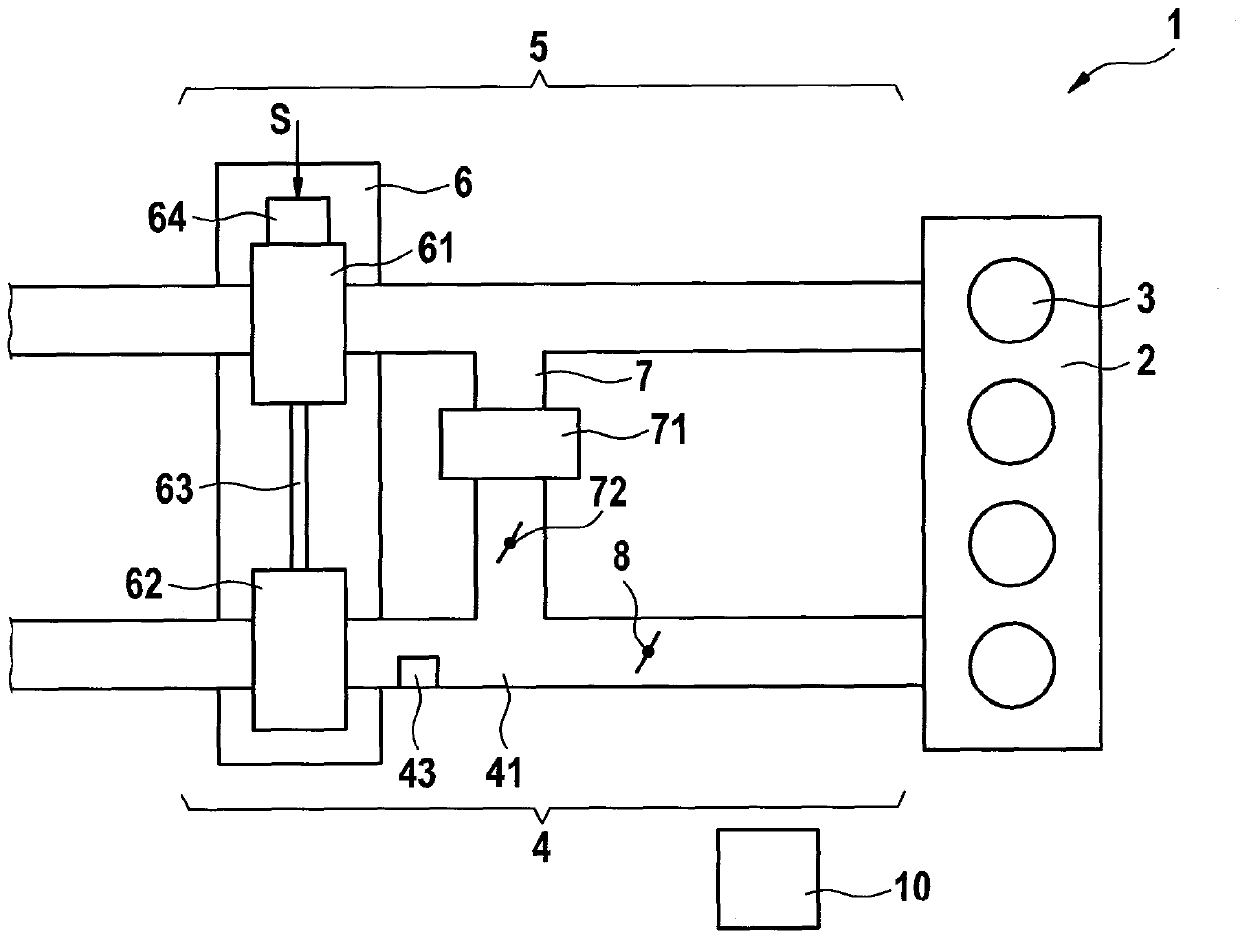

[0039] figure 1 An engine system 1 is shown with an internal combustion engine 2 , which generally includes a plurality of cylinders 3 . The internal combustion engine 2 can operate according to the four-stroke principle and can be designed in particular as a fuel-using internal combustion engine, in particular as a diesel engine.

[0040] Fresh air is supplied to cylinders 3 of internal combustion engine 2 via an intake system 4 . During operation, fuel is injected into the combustion chambers of the cylinders 3 according to the load requirements, after combustion of which the combustion exhaust gases are discharged via exhaust gas outlets 5 .

[0041] An exhaust gas-driven charging device 6 is arranged in the intake system 4 and in the exhaust gas outlet 5 . The charging device 6 comprises a turbine 61 which is arranged in the exhaust gas outlet 5 and serves to convert the exhaust gas enthalpy of the combustion exhaust gas into mechanical energy. Furthermore, a compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com