Novel metal shearing type damper

A damper and shear type technology, applied in building types, building components, earthquake resistance, etc., can solve the problems of precise control of unfavorable damper performance, affecting the local stress environment of components, unfavorable building installation requirements, etc., to improve boundary conditions and Constraints, Avoidance of Welding Stress, Effect of Improving Feasibility

Pending Publication Date: 2020-10-13

ZHEJIANG JIANKE DAMPING SCI & TECH CO LTD

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The application of stiffeners will affect the local stress environment of components, which is not conducive to the precise control of damper performance, and in order to meet the corresponding force requirements, the volume is often too large, which is not conducive to the needs of building installation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

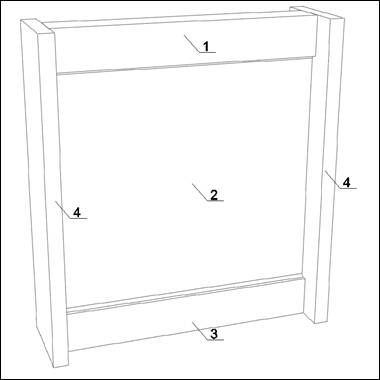

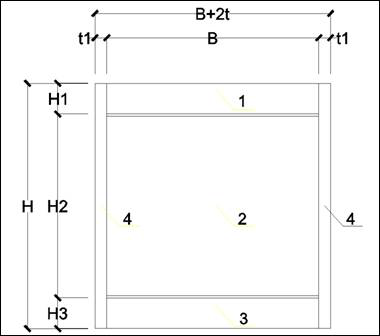

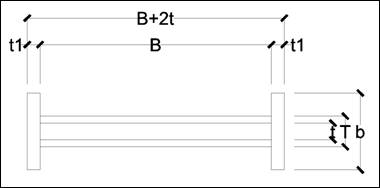

[0014] Such as figure 1 , 2 The structure of the new metal shear damper shown in the figure includes a special-shaped connection section 1 at the lower end of the core plate, an energy-dissipating section 2 at the middle section, a special-shaped connection section 3 at the upper end, and flange plates 4 on both sides. The 1, 2, and 3 are integrated After chemical processing, it is welded with 4 to form a whole.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a metal shearing type damper structure form. The metal shearing type damper structure form comprises a core plate lower end special-shaped connecting section, a middle sectionenergy consumption section capable of controlling a core plate to be reasonable in slenderness ratio, a core plate upper end special-shaped connecting section and flange plates on the two sides, the upper section, the middle section and the lower section of the core plate are formed by integrally machining a mild steel plate, it is guaranteed that steel performance of the energy consumption section is fully exerted, and stress is reasonably transmitted. Under the same load, the size, the weight and the manufacturing cost of a damper are greatly reduced, accurate simulation can be carried out through numerical simulation, consistency of damper unit parameters in an actual product and the overall structural design is kept, and the metal shearing type damper structure form is wide in application range, efficient and reliable.

Description

Technical field: [0001] The invention relates to the field of construction engineering, and relates to a metal shear damper among metal dampers. Background technique: [0002] In order to control the dynamic response of building structures, especially high-rise building structures, under wind load and earthquake load, some mechanical devices are often used to dissipate wind vibration and earthquake action and introduce energy-consuming components to protect the main load-bearing components. This is energy dissipation and shock absorption technology. Applications in building structures. Metal shear type steel plate dampers have stable energy dissipation capability and low sensitivity to the frequency of external force, and are widely used in construction projects to improve the safety performance of buildings under large earthquakes. At present, the traditional metal shear damper pays more attention to improving the material performance and improving the fatigue performance ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/98E04H9/02

CPCE04H9/021

Inventor 杜汉华姚东

Owner ZHEJIANG JIANKE DAMPING SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com