A method of manufacturing a spiral electric horn

A manufacturing method and technology of electric horn, applied in the direction of electrical components, sensors, etc., can solve the problems such as quality cannot be guaranteed, improved, glue overflow, etc., achieve good social and economic benefits, improve sound transmission quality, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

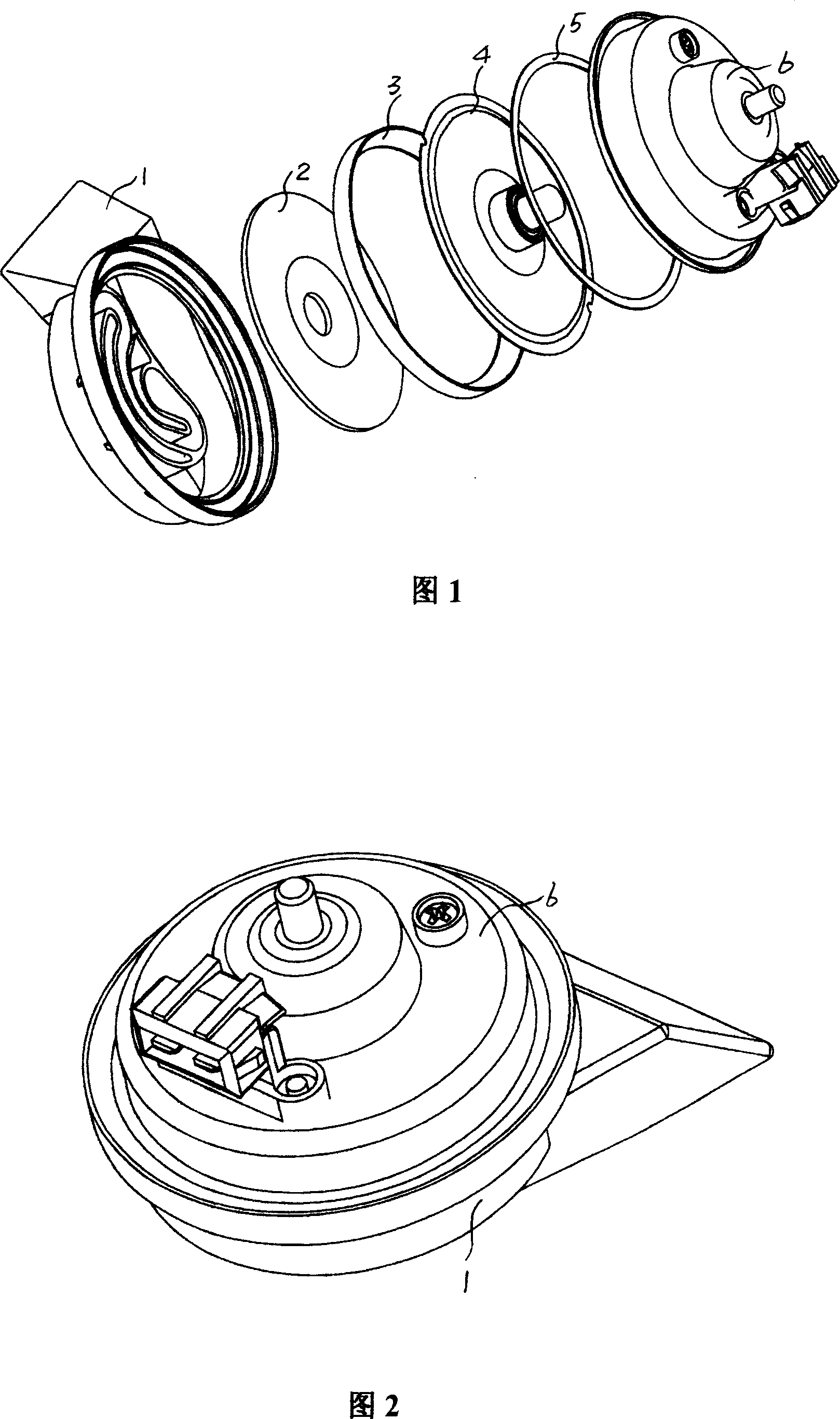

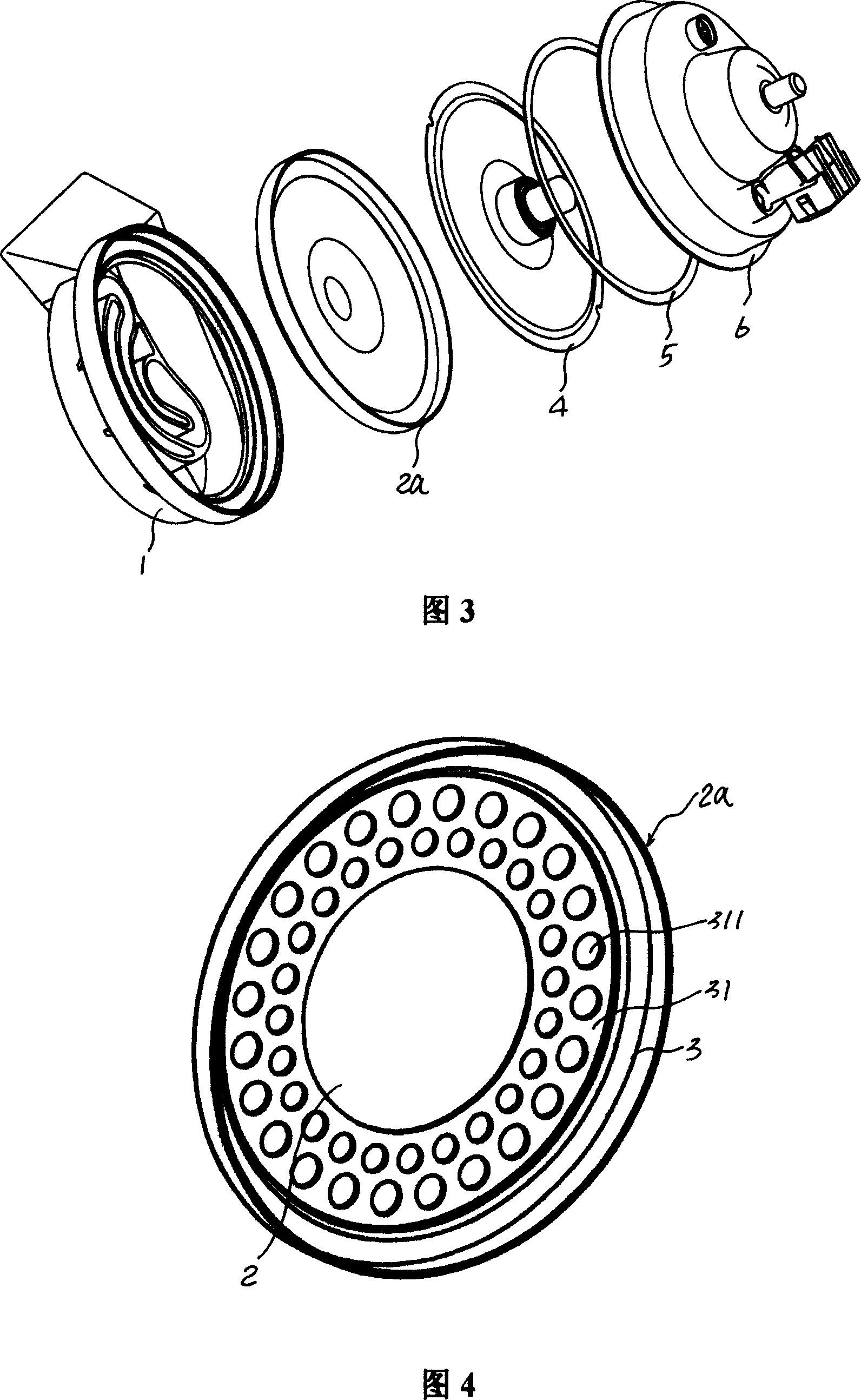

[0014] see figure 2 and image 3 , a method for manufacturing a spiral electric horn, comprising the following steps:

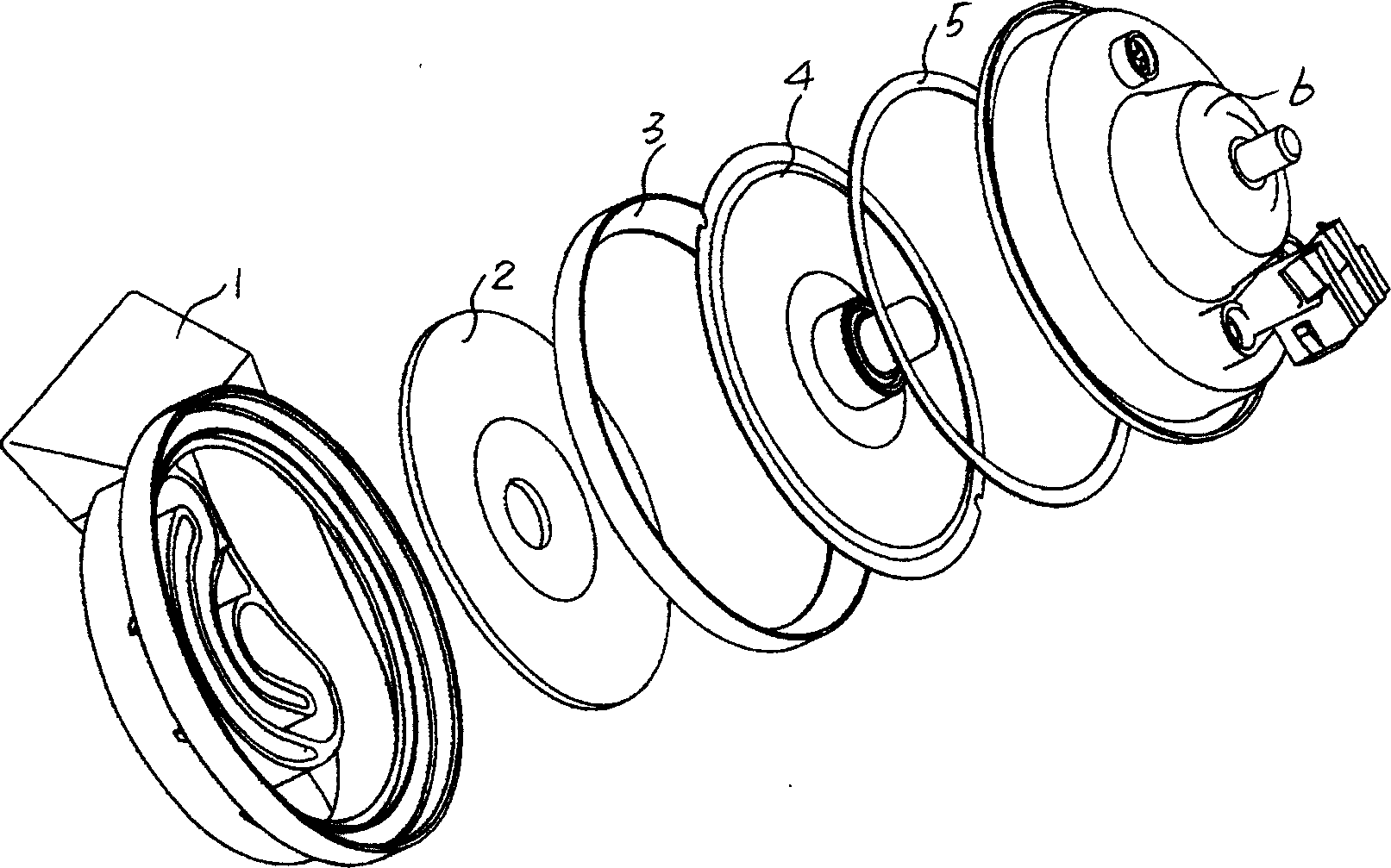

[0015] 1. Prepare speaker tube 1, diaphragm assembly 4, liner 5, chassis assembly 6, tight ring and speaker cover assembly 2a, wherein speaker cover 2 is compounded with the reinforcement surface of tight ring 3 31 combined into one, so that the tight ring 3 is embedded on the speaker cover 2 as an insert (see Figure 4 );

[0016] 2. Rivet the tight ring and speaker cover assembly 2a with the diaphragm assembly 4, liner 5 and chassis assembly 5 to form a speaker subassembly;

[0017] 3. Weld the horn sub-assembly and the loudspeaker tube 1 together by ultrasonic waves to form a spiral electric horn.

[0018] see Figure 4 , when the speaker cover 2 is compounded on the reinforcement surface 31 of the tight ring 3, the combination part of the speaker cover 2 and the through hole 311 on the reinforcement surface 31 of the tight ring 3 will be embedded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com