Indoor model testing device and testing method employing air-pressure splitting vacuum preloading method

A technology of vacuum preloading method and indoor model, which is applied in the field of the pneumatic splitting vacuum preloading method to strengthen the soft soil model test, and the pneumatic splitting vacuum preloading method to strengthen the soft soil model test device field, which can solve the problems of insufficient depth, etc. Reasonable physical simulation conditions, low cost, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

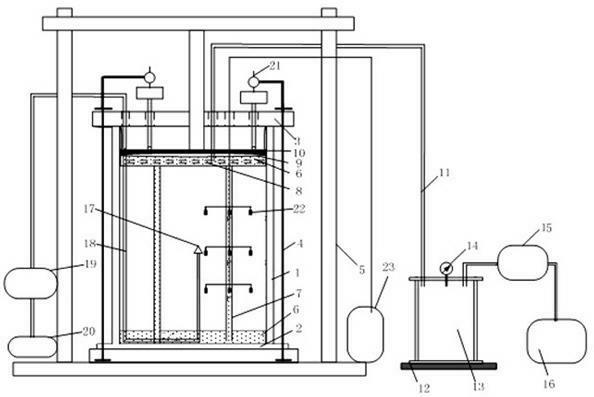

[0029] Such as figure 1 Shown: an indoor model test device of air pressure splitting vacuum preloading method, including model tank, stacking system, vacuum loading system, air pressure splitting system and measurement system;

[0030] The model tank is composed of a plastic drum 1, a plastic drum base 2, a plastic drum top cover 3, and steel bars 4; wherein the plastic drum 1 is an organic transparent plastic drum with a diameter of 50 cm and a height of 120 cm. The plastic drum base 2 is a high-strength plastic plate (PVC) or steel plate with a thickness of 2 cm and a diameter of 60 cm; the plastic drum top cover 3 is made of the same material as the base. The plastic drum base 2 is completely sealed with the plastic drum 1. The plastic drum base 2 and the plastic drum top cover 3 have round holes with a diameter of 10mm and threads, which are u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com