Fluorine-modified acrylic resin composite anticorrosive coating preparation process and device

A compound technology of fluorine-modified acrylic acid and resin, which is applied in the direction of coating, electrolytic coating, anodic oxidation, etc., and can solve the problems of small application range, small application range, and poor airtightness of gland plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

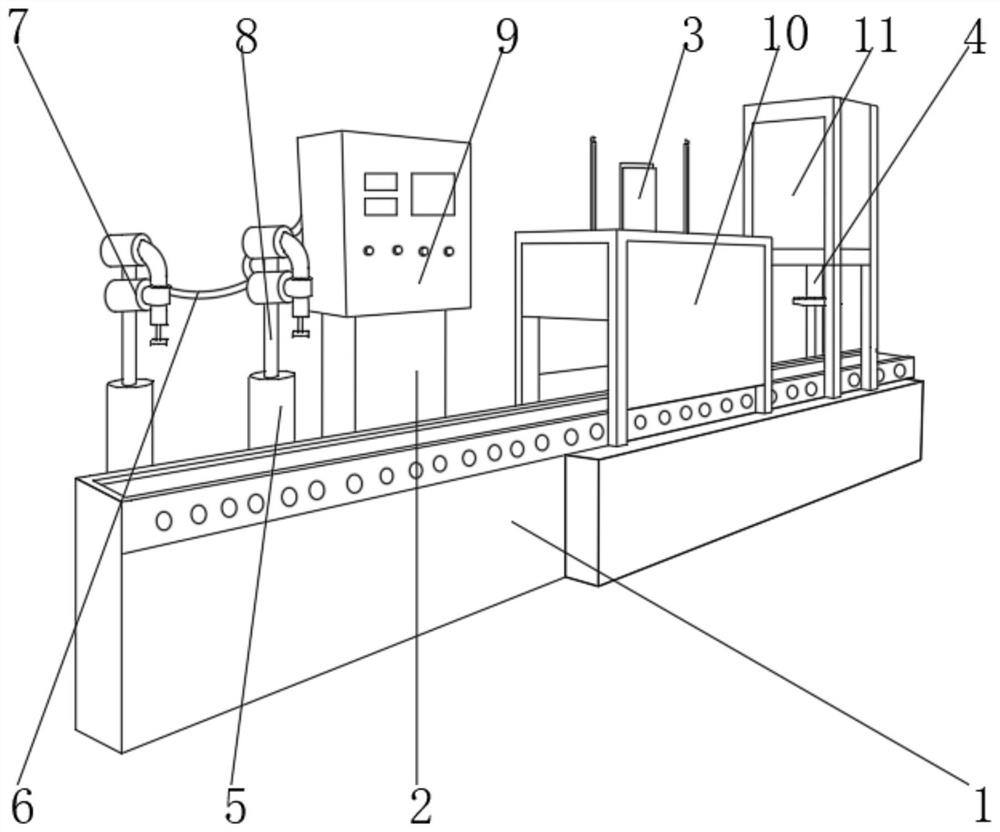

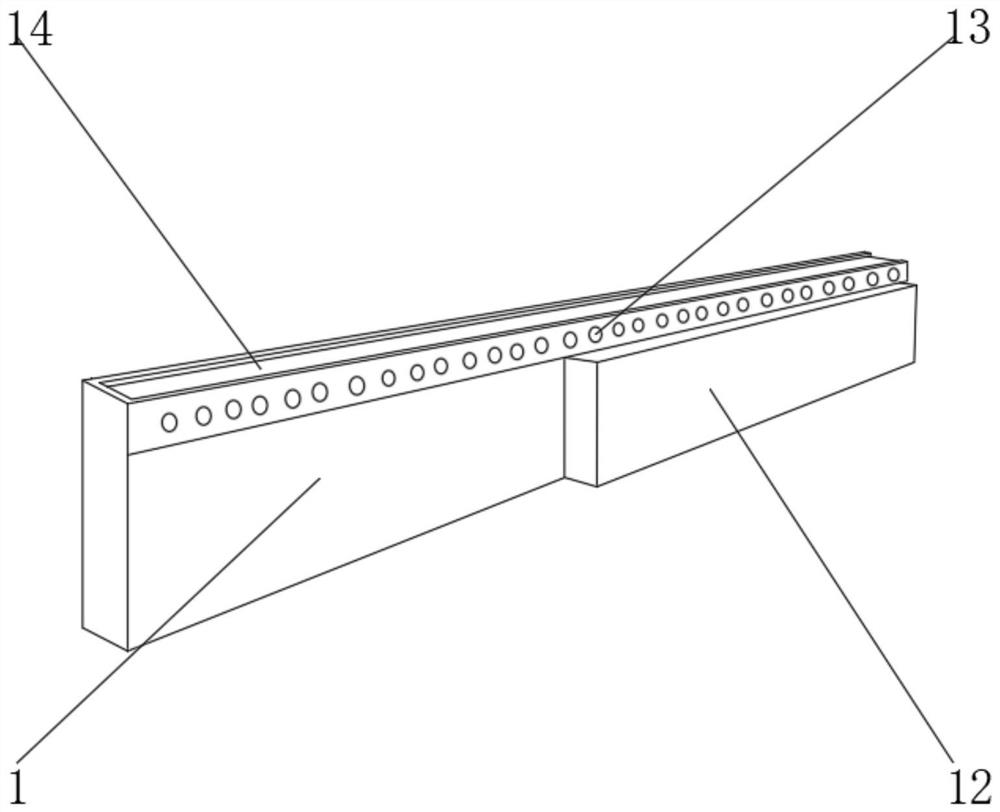

[0034] Such as Figure 1-5 As shown, the fluorine-modified acrylic resin composite anticorrosion coating preparation device includes a device chassis 1, and one side of the device chassis 1 is fixedly connected with a cylinder base 5, a connection box 2, and a side chassis 12, and the inner side of the cylinder base 5 is fixedly connected with a Paint delivery pipe 8, the upper end of paint delivery pipe 8 is fixedly connected with nozzle filling mechanism 7, one side of nozzle filling mechanism 7 is fixedly connected with connecting wire 6, and the upper end of connection box 2 is fixedly connected with control box 9.

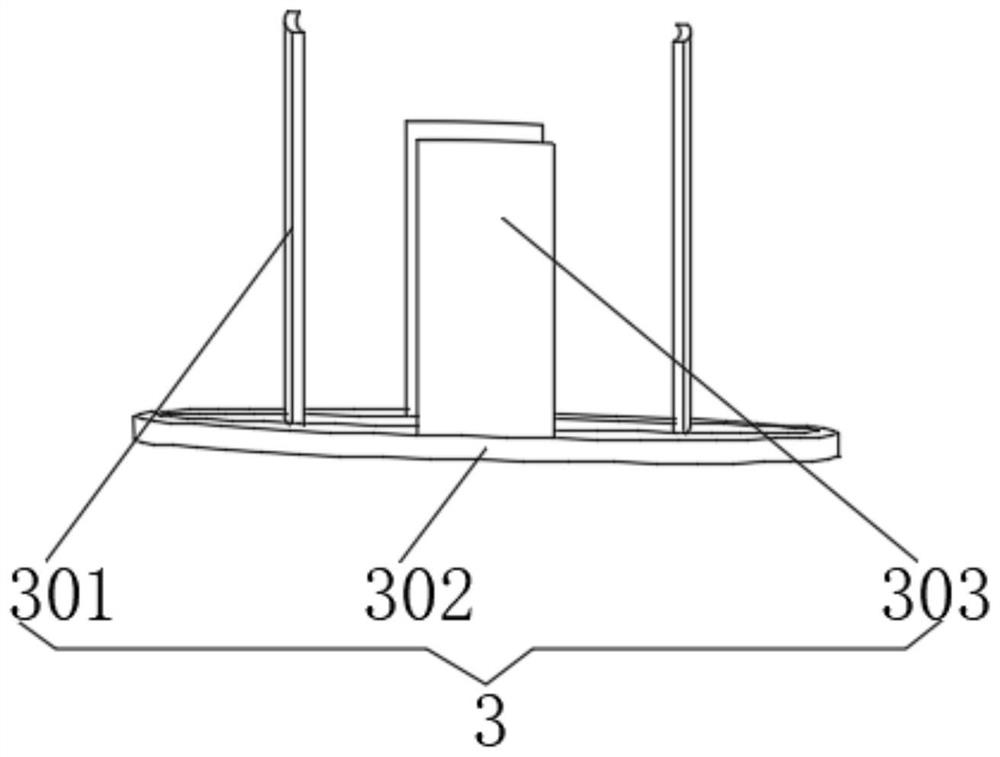

[0035] The upper end of the side cabinet 12 is fixedly connected with an upper cover device 10 and a capping device 11, and the upper end of the upper cover device 10 is fixedly connected with an adjustable lid placement mechanism 3. The cover mechanism 4 is movably connected to the inside of the device cabinet 1 with a conveyor belt 14 , and the lower end of ...

Embodiment 2

[0043] Such as figure 1 , 2 , 6, and 7, the fluorine-modified acrylic resin composite anti-corrosion coating preparation device includes a device cabinet 1, and one side of the device cabinet 1 is fixedly connected with a cylinder base 5, a connection box 2, a side cabinet 12, and a cylinder base 5. The inner side is fixedly connected with a paint delivery pipe 8, the upper end of the paint delivery pipe 8 is fixedly connected with a nozzle filling mechanism 7, one side of the nozzle filling mechanism 7 is fixedly connected with a connecting wire 6, and the upper end of the connection box 2 is fixedly connected with a control box 9 .

[0044] The upper end of the side cabinet 12 is fixedly connected with an upper cover device 10 and a capping device 11, and the upper end of the upper cover device 10 is fixedly connected with an adjustable lid placement mechanism 3. The cover mechanism 4 is movably connected to the inside of the device cabinet 1 with a conveyor belt 14 , and ...

Embodiment 3

[0052] Such as figure 1 , 2 , 8, the fluorine-modified acrylic resin composite anti-corrosion coating preparation device includes a device chassis 1, and one side of the device chassis 1 is fixedly connected with a cylinder base 5, a connection box 2, and a side chassis 12, and the inner side of the cylinder base 5 is fixed. Connected with a paint delivery pipe 8, the upper end of the paint delivery pipe 8 is fixedly connected with a nozzle filling mechanism 7, one side of the nozzle filling mechanism 7 is fixedly connected with a connecting wire 6, and the upper end of the connection box 2 is fixedly connected with a control box 9.

[0053] The upper end of the side cabinet 12 is fixedly connected with an upper cover device 10 and a capping device 11, and the upper end of the upper cover device 10 is fixedly connected with an adjustable lid placement mechanism 3. The cover mechanism 4 is movably connected to the inside of the device cabinet 1 with a conveyor belt 14 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com