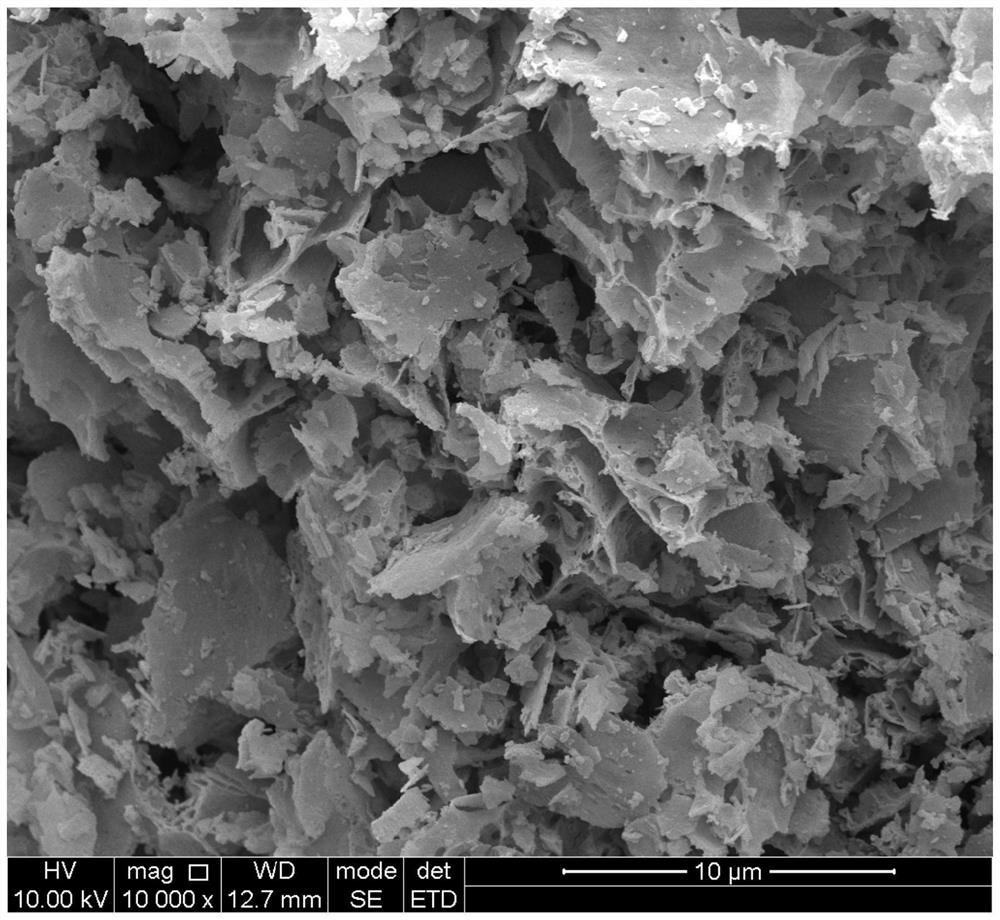

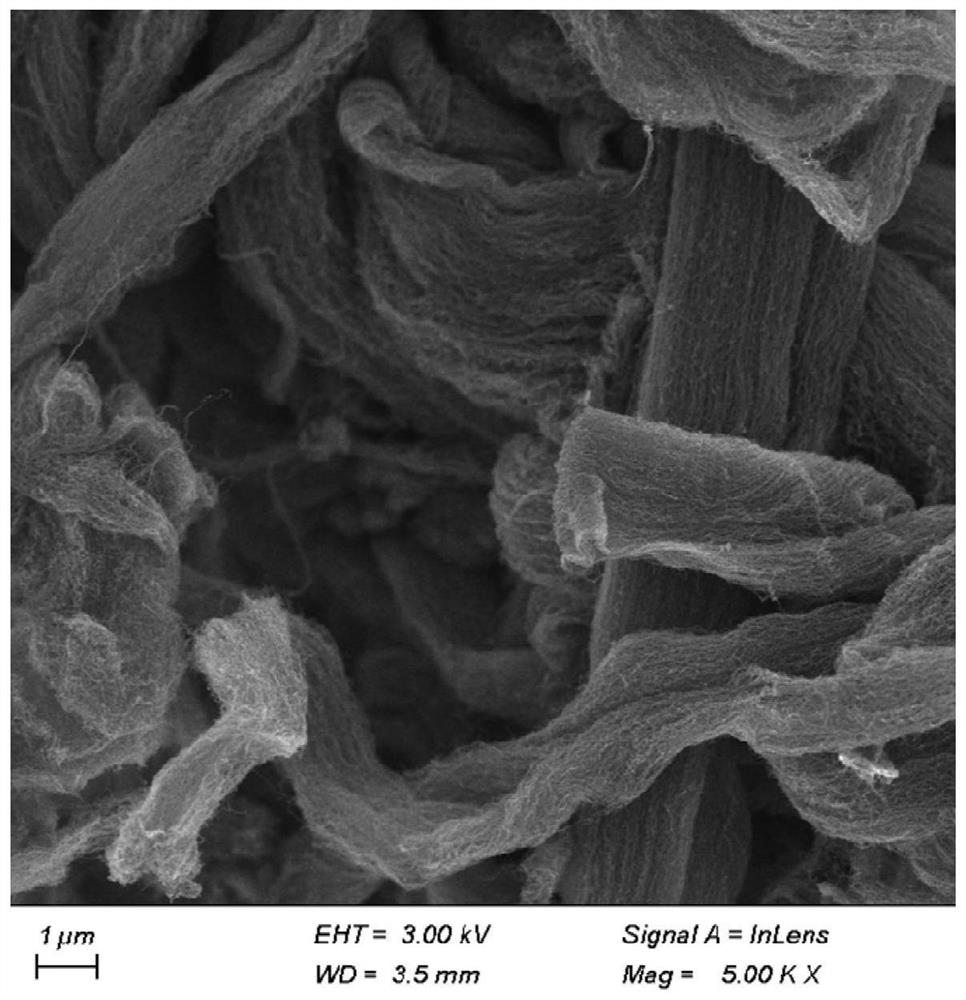

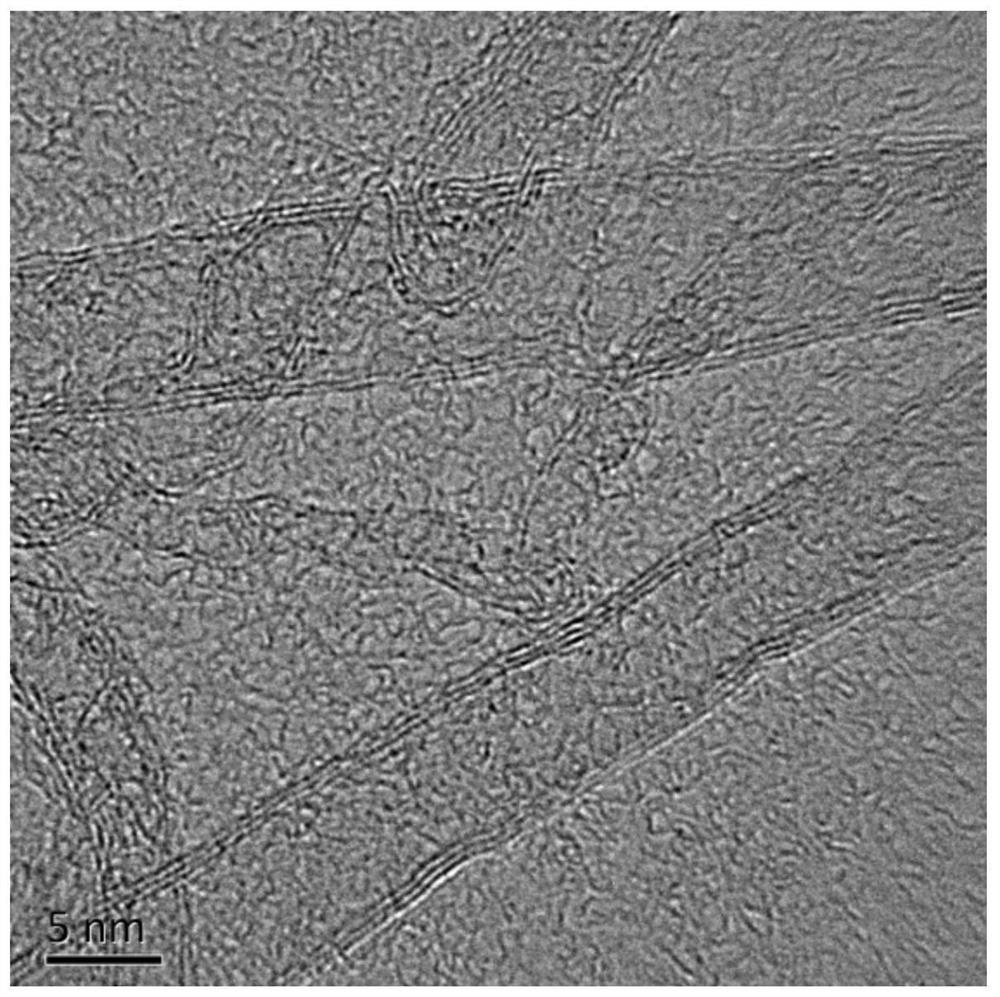

Catalyst for preparing carbon nanotubes as well as preparation method and application thereof

A catalyst and template technology, applied in the field of carbon nanomaterials, can solve the problems of low catalyst production efficiency, long time consumption, difficulty in adopting a fluidized operation process with high space velocity, etc., and achieve the effect of improving industrial production efficiency and increasing growth rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] This example provides a kind of preparation method of catalyst, and the steps are as follows:

[0096] Step 1: Dissolve ferric nitrate nonahydrate and cobalt nitrate hexahydrate (the total molar mass of the two is 0.5mol), 1.5mol magnesium nitrate hexahydrate, 1.5mol aluminum nitrate nonahydrate and ethylenediaminetetraacetic acid in water at 50°C Stir and dissolve at ~60°C, then keep stirring for 1 hour to form a metal-organic complex.

[0097] Step 2: Add 0.22mol flake Al(OH) to the solution in Step 1 3 , and stirred at 50°C to 60°C for 2h.

[0098] Step 3: Add guar gum thickener to the dispersion in step 2, and continue to stir at 50° C. to 60° C. for 2 hours to obtain a precursor dispersion with a viscosity (25° C.) of about 4000 mPa·s.

[0099] Step 4: Put the precursor dispersion liquid in a high-temperature furnace at 450°C for calcination, and then crush it into 50-200 mesh to obtain the catalyst of this example.

Embodiment 2

[0101] This example provides a kind of preparation method of catalyst, and the steps are as follows:

[0102] Step 1: Ferric nitrate nonahydrate and cobalt nitrate hexahydrate (the total molar mass of both is 0.5mol), 1.0mol magnesium nitrate hexahydrate, 1.3mol aluminum nitrate nonahydrate and citric acid are dissolved in water at 60°C to 70°C Stir and dissolve at high temperature, and then keep stirring for 1 hour to form a metal-organic complex.

[0103] Step 2: Add 1.4 mol of flake Mg(OH) to the solution in Step 1 2 , and stirred at 60°C to 70°C for 2h.

[0104] Step 3: Add guar gum thickener to the dispersion in step 2, and continue to stir at 60°C to 70°C for 2h to obtain a precursor dispersion with a viscosity (25°C) of about 2000mPa·s.

[0105] Step 4: Put the precursor dispersion in a high-temperature furnace at 500°C for calcination, and then crush it into 50-200 mesh to obtain the catalyst of this example.

Embodiment 3

[0107] This example provides a kind of preparation method of catalyst, and the steps are as follows:

[0108] Step 1: Ferric nitrate nonahydrate and cobalt nitrate hexahydrate (the total molar mass of the two is 0.5mol), 0.8mol magnesium nitrate hexahydrate, 0.8mol aluminum nitrate nonahydrate and polyacrylic acid are dissolved in water at 70°C to 80°C Stir and dissolve at high temperature, and then keep stirring for 1 hour to form a metal organic ligand complex.

[0109] Step 2: Add flake aluminum-magnesium hydrotalcite carrier (the molar number of Mg and Al is 2.1 mol) to the solution in step 1, and stir at 50° C. to 80° C. for 2 hours.

[0110] Step 3: Add guar gum thickener to the dispersion in step 2, and continue to stir at 70° C. to 80° C. for 2 hours to obtain a precursor dispersion with a viscosity (25° C.) of about 20,000 mPa·s.

[0111] Step 4: Put the precursor dispersion in a high-temperature furnace at 500°C for calcination, and then crush it into 50-200 mesh to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com