Hot pressed sintering method of ceramic products with high density and complex shapes

A technology of ceramic products and hot pressing sintering, which is applied in the direction of ceramic forming machines and manufacturing tools, and can solve the problems of reducing the mechanical properties of ceramic parts, slow temperature control technology, and grain growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

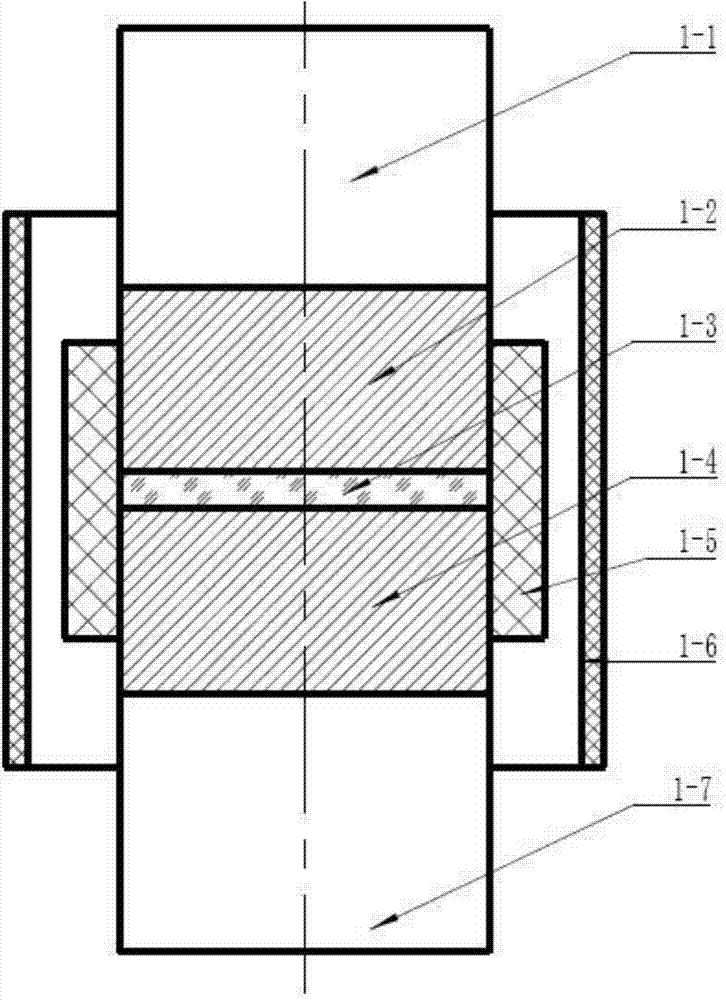

Image

Examples

Embodiment 1

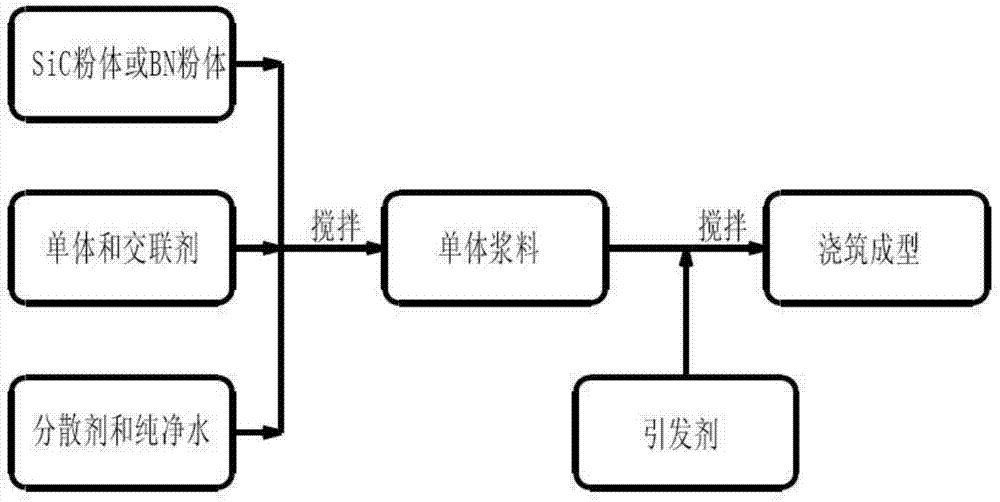

[0036] The preparation process of gel cast SiC and BN is as follows figure 2 Shown:

[0037] The process steps for preparing gel-cast SiC ceramics and BN ceramics are as follows:

[0038] (1) Configure the monomer solution:

[0039] Acrylamide (AM) monomer and cross-linking agent methylenebisacrylamide (MBAM) were prepared in a certain proportion and dissolved in deionized water to prepare a monomer solution; the monomer solution contained 11.4wt% AM and MBAM It is 1wt% and contains 87.6wt% purified water. Fully dissolve the prepared monomer solution, filter it with filter paper and seal it in a glass container for later use.

[0040] (2) Prepare dispersant solution:

[0041] Mix ammonium citrate (DAC) and water according to the ratio of 10g ammonium citrate (DAC) + 90g water. After fully dissolving the prepared dispersant solution, filter it with filter paper and seal it in a glass container for later use.

[0042] (3) Mixture:

[0043] a. Weigh 5 kg of zirconia grinding...

Embodiment 2

[0071] Hot-pressed target ceramic Si 3 N 4 , with C powder and BN as the mold material:

[0072] (1) First, configure Si according to the process steps of Example 1 3 N 4 slurry, and gel-form the Si 3 N 4 slurry;

[0073] (2) The mixture of C powder and BN is used as the mold material, wherein the mass fraction of C powder is 80%, and the mass fraction of BN is 20%. Using cold isostatic pressing, a block is formed under a pressure of 200MPa, and a CNC milling machine is used. Processed out with Si 3 N 4 The shape and size of the upper and lower sides of the gel;

[0074] (3) Combine the processed C powder and BN mixture mold material with Si 3 N 4 The gel body is well assembled and coordinated, and the Si with complex structure can be completed according to the hot pressing process and post-treatment process of Example 1. 3 N 4 Manufacture of ceramic products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

| Theoretical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com