Preparation of continuous hole graded ceramic tube

A technology of ceramic tubes and continuous holes is applied in the field of preparation of continuous-pore gradient ceramic tubes, which can solve the problems of complicated and difficult manufacturing process of continuous-pore gradient ceramics and high centrifugal speed, and achieves the elimination of vacuum degassing procedures, easy operation, and centrifugal force. The effect of low speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

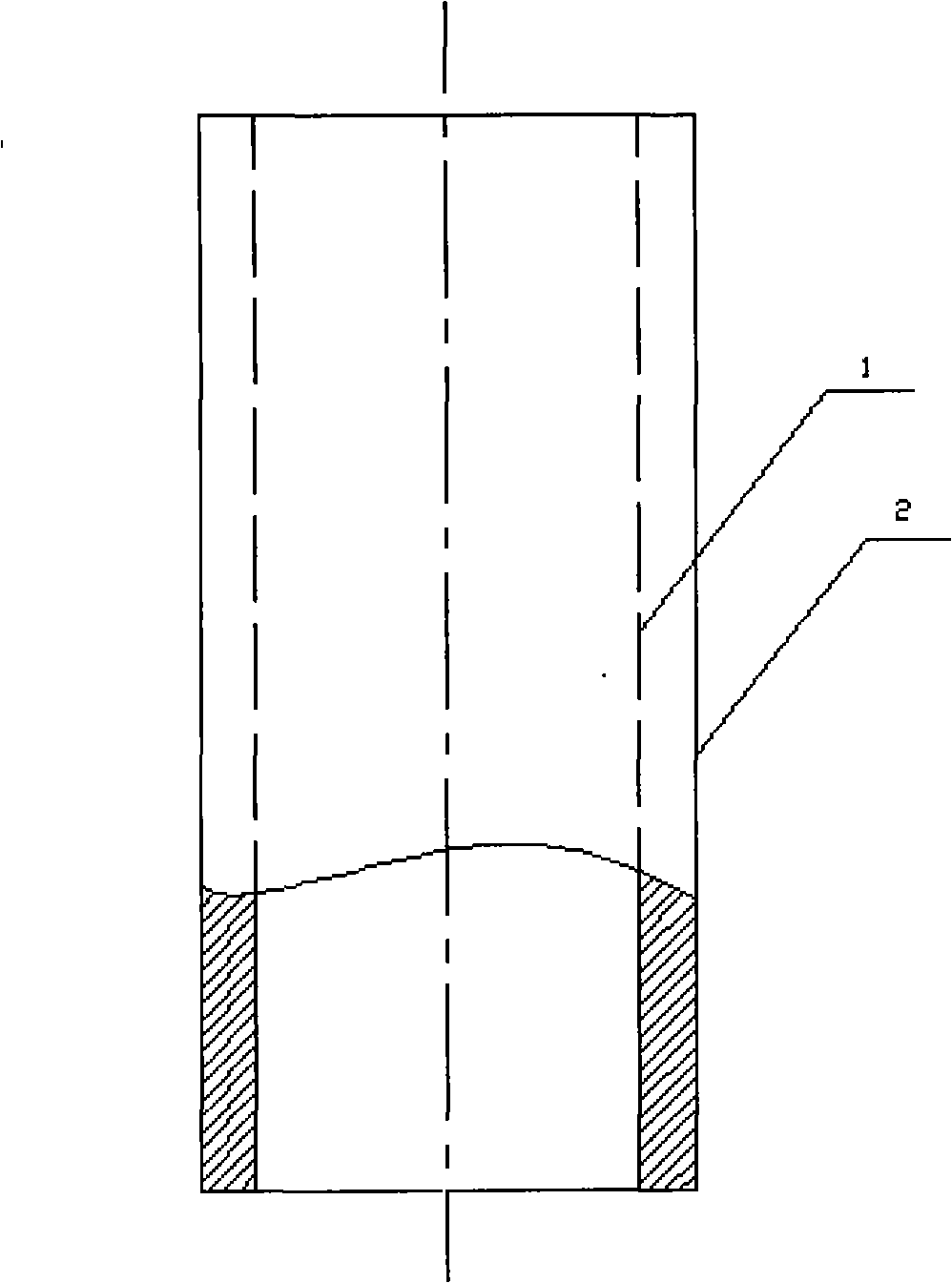

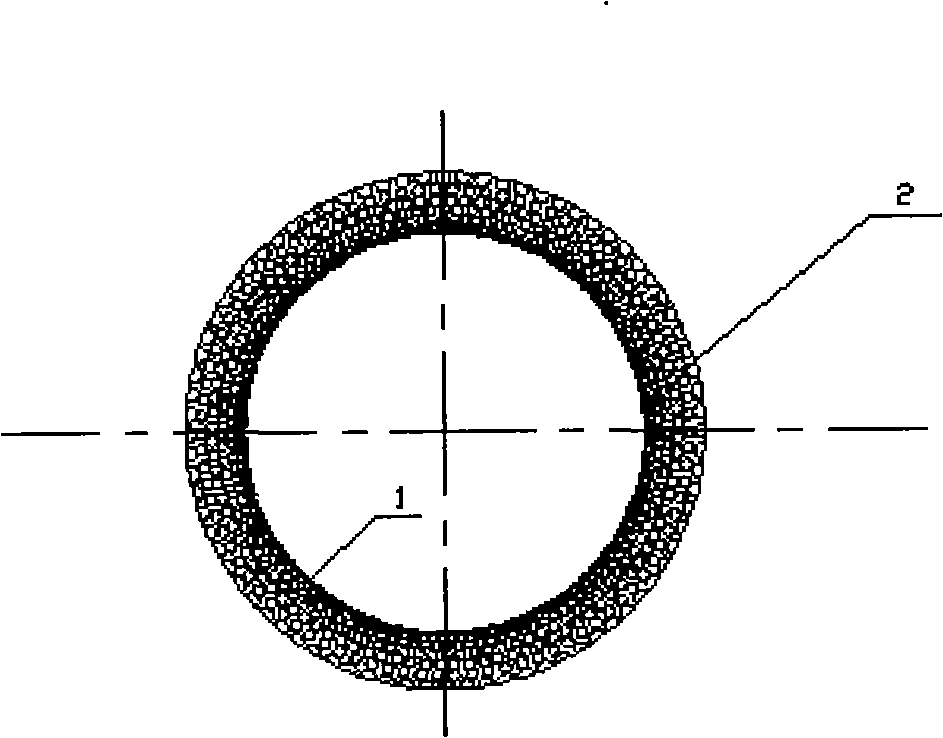

[0058] The preparation method of the continuous hole gradient ceramic tube of the present invention includes batching, centrifugal gel forming, drying and sintering.

[0059] Preparation of slurry: First, add alumina powder, organic monomer HEMA and cross-linking agent MBAM, and then add TAC, and mix thoroughly by stirring to prepare a slurry with a viscosity of 100 mPa·s.

[0060] The mass ratio of slurry is: alumina powder 70%, organic monomer (HEMA) 2.5%, crosslinking agent (MBAM) 0.1%, deionized water 27%, dispersant (TAC) 0.4%.

[0061] Centrifugal gel forming: take out 20g of slurry, add catalyst tetramethylethylenediamine (TEMED) and initiator ammonium persulfate (APS) (respectively 0.005% and 0.008% of the mass of ceramic powder) to it, after stirring for 5min Inject the stainless steel centrifuge tube, install it horizontally on the self-made centrifugal forming machine and carry out centrifugal forming with the rotating speed of 5000rpm. After 5 minutes, the centrif...

Embodiment 2

[0067] First, silica powder, organic monomer NMA and cross-linking agent MBAM were added, and then TAC was added, and the slurry with a viscosity of 150 mPa·s was prepared by stirring and mixing thoroughly. The mass ratio of the slurry is: 80% of silicon oxide powder, 4% of organic monomer (NMA), 0.1% of crosslinking agent (MBAM), 15.6% of deionized water, and 0.3% of dispersant (TAC).

[0068] Centrifugal gel forming: take out 30g slurry, add catalyst TEMED and initiator APS (respectively 0.003% and 0.007% of the mass of ceramic powder) to the slurry, stir it for 2min and pour it into a stainless steel centrifuge tube, install it horizontally in a self-made Centrifugal molding is performed at a speed of 5000rpm on a centrifugal molding machine. After 5 minutes, the centrifuge tube was heated to 80°C while maintaining the centrifugation speed and kept for 50 minutes to shape the green body.

[0069] Drying: After centrifugation, dry the wet billet at 50°C for 30 hours. After ...

Embodiment 3

[0072] First, mix ceramic powder of alumina and titanium oxide, organic monomer NMA and crosslinking agent MBAM, and then add PAA-NH 4 : solution (mass fraction 30%), and a slurry with a viscosity of 85mPa·s was prepared through thorough mixing.

[0073] The mass ratio of slurry is: ceramic powder 55% (powder mass ratio: alumina / titanium dioxide = 90 / 10), organic monomer 10%, crosslinking agent 1%, deionized water 29%, dispersant 5% .

[0074] Centrifugal gel forming: take out 40g of slurry, add catalyst TEMED and initiator ammonium persulfate (0.003% and 0.007% of the mass of ceramic powder respectively) into the slurry, stir for 2min and pour into a stainless steel centrifuge tube, install it horizontally Centrifugal molding was carried out at a speed of 2000rpm on a self-made centrifugal molding machine. After 10 minutes, the centrifuge tube was heated to 80°C while maintaining the centrifugation speed and kept for 50 minutes to shape the green body.

[0075] Drying: Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com