Prefabricated refractory wallboard used for graphitized furnace and manufacture method thereof

A technology of refractory wall panels and graphitization furnaces, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as high production costs, low production efficiency, and high labor intensity of workers, and achieve increased production capacity , simple structure, and shorten the maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

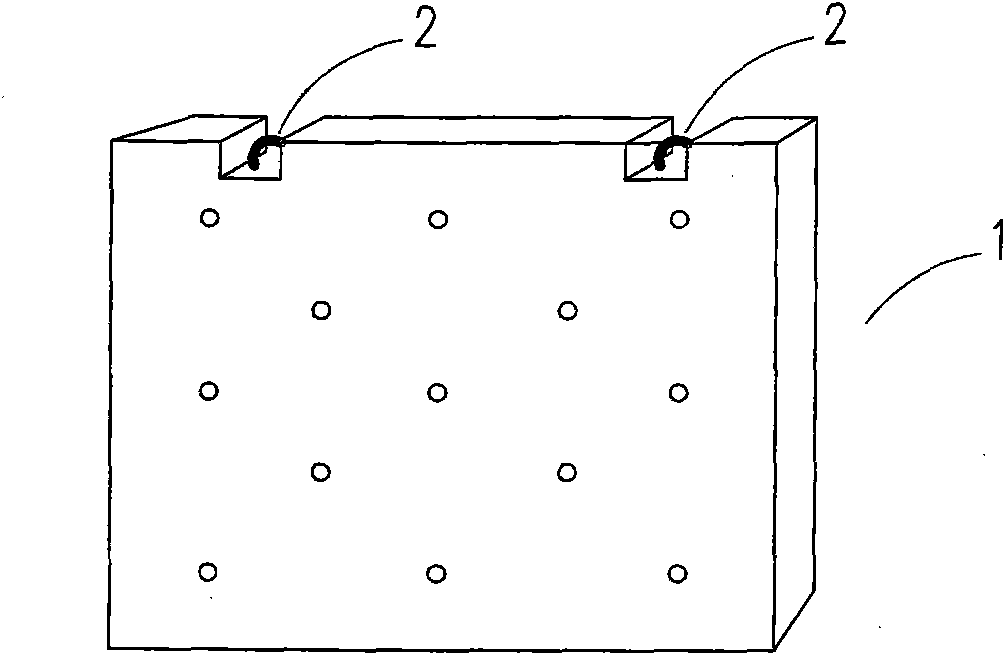

[0015] Such as figure 1 As shown, an embodiment of the present invention includes a wall panel body 1 provided with a steel skeleton structure, and the wall panel body 1 is provided with a hoisting ring 2 and several horizontally through ventilation holes 3 . The principle is: change the original masonry furnace wall into the prefabricated fire-resistant wall panel structure of the present invention, the wall panel body 1 is provided with a hoisting ring 2, and the hoisting ring 2 can be used for overall hoisting; the wall panel body 1 is prefabricated with a The horizontal ventilation hole 3 replaces the ventilation hole built on the original masonry furnace wall, and the steel skeleton structure can enhance the overall strength of the wallboard body 1, and the purpose is to ensure the strength requirements of multiple hoisting. The on-site construction period is short, which reduces the labor intensity of workers maintaining the graphitization furnace, shortens the maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com