Sliding brick and preparation method thereof

A sliding brick and mixture technology, which is applied in the field of refractory materials, can solve the problems of poor wear resistance and achieve the effects of improved wear resistance, high plasticity, and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides the preparation method of described skateboard brick, comprises the following steps:

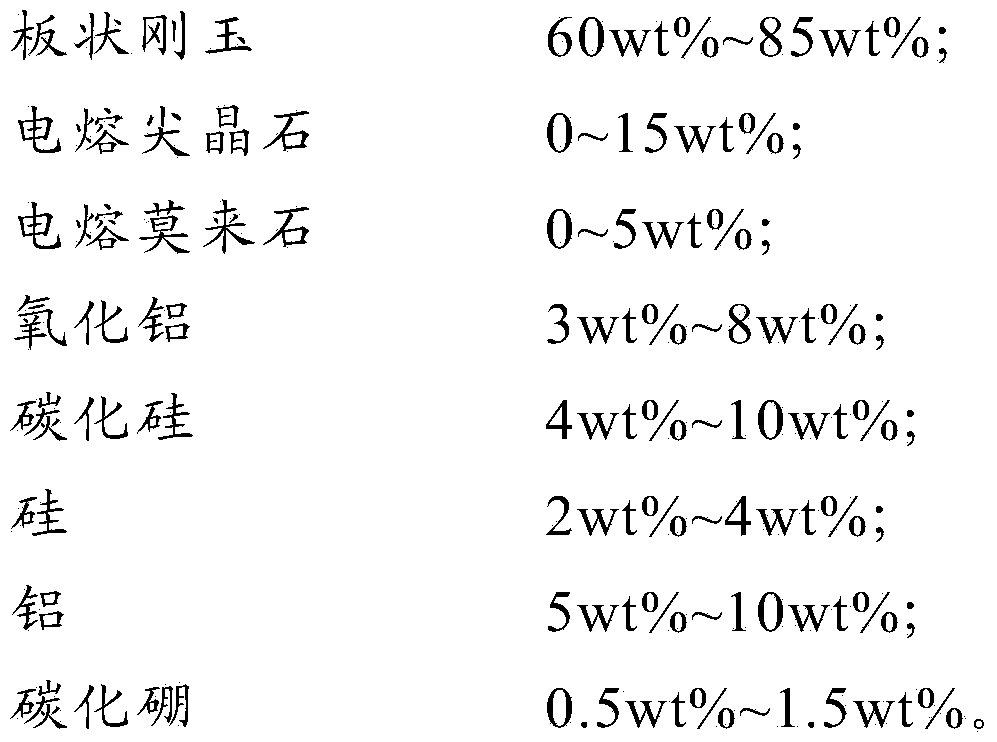

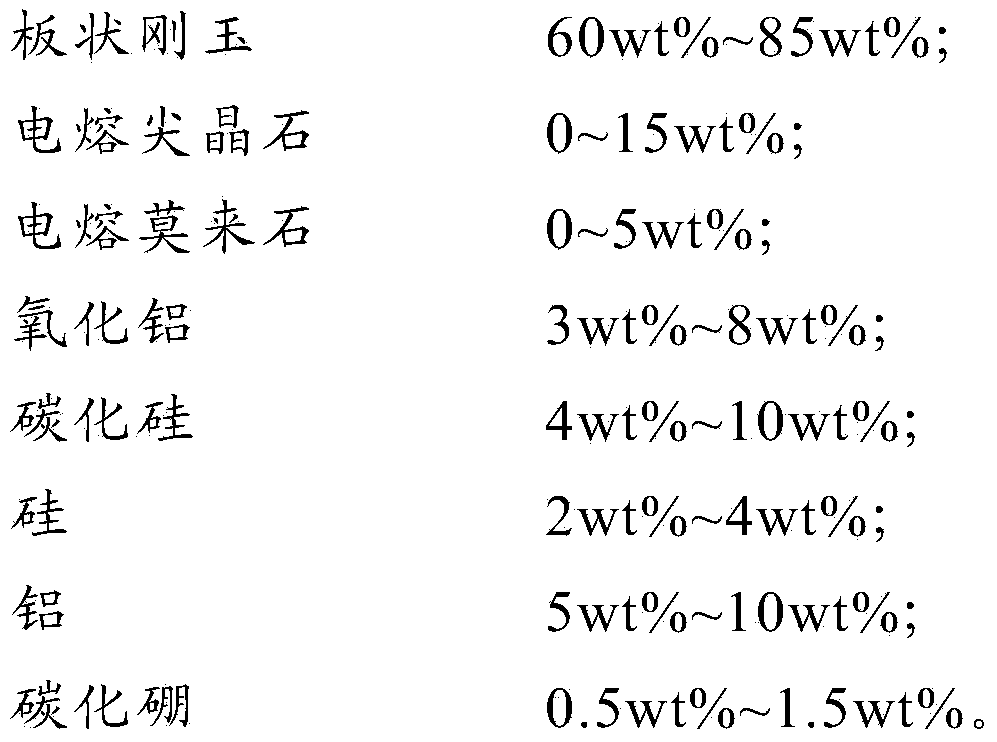

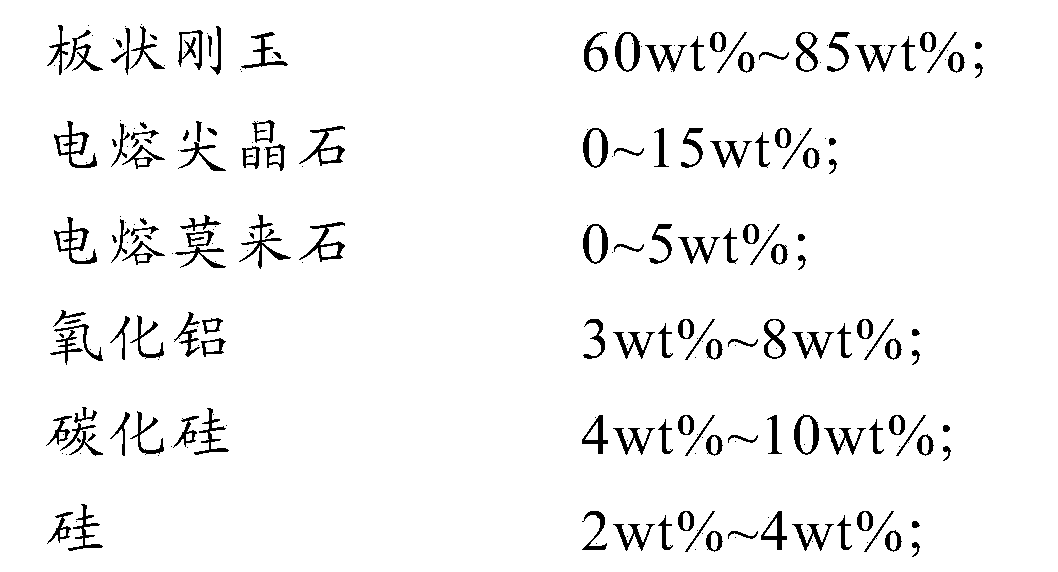

[0037] 60wt%~85wt% of tabular alumina, 0~15wt% of fused spinel, 0~5wt% of fused mullite, 3wt%~8wt% of alumina micropowder, 4wt%~10wt% of carbonized Silicon, 2wt%-4wt% silicon, 5wt%-10wt% aluminum and 0.5wt%-1.5wt% boron carbide are mixed and milled to obtain mud;

[0038] After mixing and grinding the mud, pressing it to obtain a sliding slab;

[0039] The sliding slab is dried and fired to obtain the sliding brick; the firing is light firing or high temperature firing.

[0040] According to the present invention, in the process of preparing skateboard bricks, firstly, the raw materials are mixed, and the materials are mixed and milled to make them evenly mixed to obtain mud materials. In the process of preparing the mud, in addition to adding the above-mentioned raw materials, a binder is also added. In terms of the weight percentage of the mud, ...

Embodiment 1

[0052]395kg of sintered tabular alumina of 2~1mm, 1~0.5mm, 0.5~0mm, 325 mesh, 25kg of 1~0mm, 325 mesh silicon carbide, 25kg of CL370 alumina micropowder of 2~3μm, 5kg of aluminum particles of 30~60 mesh, 180-325 mesh aluminum fine powder 20kg, 2.5kg aluminum fiber, 450-500 mesh aluminum-silicon alloy powder 15kg, 300-325 mesh simple silicon powder 10kg, 325 mesh boron carbide 2.5kg, 180 mesh resin powder 5kg and 15.2kg liquid The phenolic resin is kneaded in the kneading machine for 25 minutes, and after being trapped for 24 hours, it is kneaded again in the kneading machine for 20 minutes, and then pressed into a sliding slab by a 630-ton electric screw press, and the adobe is dried in an infrared kiln at room temperature to 180°C , heat treatment at 750°C for 10 hours in a neutral atmosphere in a well-type furnace to obtain skateboard bricks. The skateboard bricks are impregnated with asphalt, and finally smoothed, hooped, assembled, and coated to obtain finished skateboards....

Embodiment 2

[0054] 302.5kg of sintered tabular alumina of 2~1mm, 1~0.5mm, 0.5~0mm, 325 mesh, 25kg of fused mullite of 1~0mm, 50kg of fused spinel of 2~0mm, CL370 of 2~3μm Alumina fine powder 30kg, 1-0mm, 325-mesh silicon carbide 30kg, 30-60-mesh aluminum particles 7.5kg, 180-325-mesh aluminum fine powder 25kg, 2.5kg aluminum fiber, 450-500-mesh aluminum-silicon alloy powder 15kg, 300 ~325 mesh elemental silicon powder 10kg, 325 mesh boron carbide 2.5kg, 180 mesh resin powder 2.5kg, 2.5kg silicone resin and 15.5kg liquid phenolic resin were mixed in the kneader for 30min, after 24h the mud was trapped again Mix and grind in the kneading machine for 15 minutes, and then use a 630-ton electric screw press to press it into a sliding slab. After being dried in an infrared kiln at room temperature to 180°C, the brick is heat-treated at 850°C for 10 hours in a neutral atmosphere in a well-type furnace. The skateboard bricks are obtained, and the skateboard bricks are impregnated with asphalt, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com