High-magnesium micro-expansive moderate heat Portland cement for water-power engineering and preparation method thereof

A hydropower engineering and micro-expansion technology, which is applied in the field of high-magnesium micro-expansion medium-heat cement for hydropower engineering and its preparation, achieves the effects of reasonable expansion and compensation for temperature drop and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

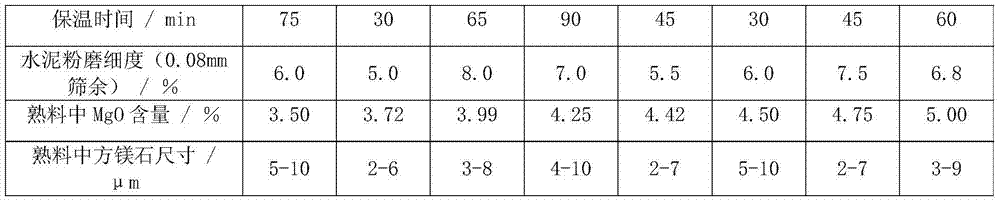

Embodiment 1-8

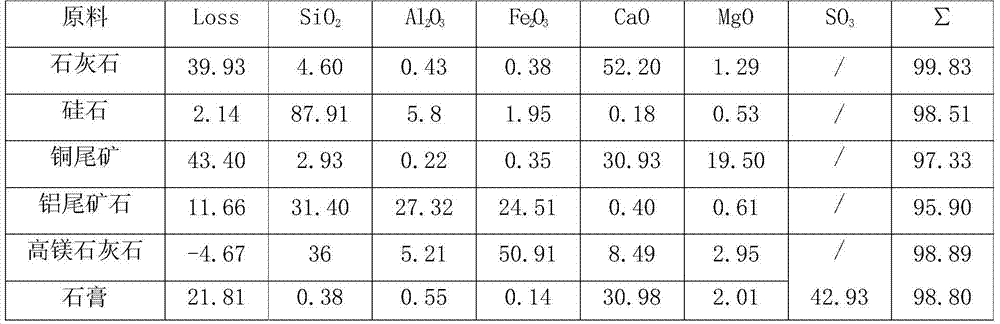

[0036] Embodiment 1-8, Raw material ratio and preparation of high-magnesium micro-expansion medium-heat cement for hydropower projects

[0037] The weight ratio of raw materials for high-magnesium micro-expansion medium-heat cement for hydropower projects is: calcium raw materials 71.09%-75.82%, silicon raw materials 9.54%-9.65%, iron raw materials 2.42%-2.56%, aluminum raw materials 5.51%- 5.91%, magnesia raw material 6.06%-11.41%, the weight ratio of cement clinker and gypsum is: 96.5:3.5-94.5:5.5, wherein,

[0038] The calcareous raw material is selected from one or more combinations of limestone, calcite, and limestone, preferably limestone;

[0039] The siliceous raw material is selected from one or more combinations of silica, shale, and sandstone, preferably silica;

[0040] The iron raw material is selected from one or more combinations of copper tailings and iron powder, preferably copper tailings;

[0041] The aluminum raw material is selected from one or more comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com