Sagger

A saggar and spinel technology, which is applied in the field of saggars for powder sintering, can solve the problems of reduced product strength and reduced thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

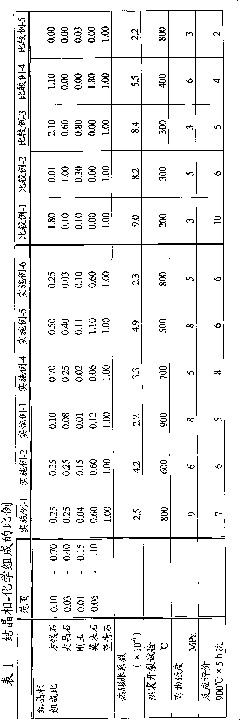

Embodiment 1~4、 comparative example 1~5

[0038] The mixture obtained by blending each raw material was kneaded and sintered to prepare samples (200 mm×200 mm, thickness 10 mm) having the composition ratios shown in Table 1. The magnesium oxide raw material used is a raw material with a purity of more than 99%. Molding is carried out by adding PVA, by hydraulic pressure molding. Sintering is carried out at 1350°C.

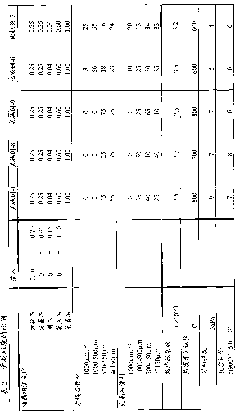

[0039] Crystal phase composition ratio

[0040] Using an X-ray diffractometer (RINT 1100K) manufactured by Rigaku Denki Co., Ltd., each sample after sintering was measured under the following conditions, and the crystal phase composition ratio was investigated.

[0041] Tube voltage: 40kV, tube current: 20mA, divergence slit 1°, scattering slit 1°, light receiving slit 0.3mm. The integral intensity is obtained by the JADE integral intensity method.

[0042] Thermal Shock Evaluation

[0043] The test pieces (120×120×11t) cut out from the obtained samples were heated at 200° C. for 1 hour, and the furna...

Embodiment 5~7

[0068] This is an example containing spinel with a particle size of 1 mm or less and periclase with a particle size of 0.5 mm or less as aggregates. Good values were shown in both bending strength and thermal shock resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com