Novel high-Q-value capacitor

A capacitor, a new type of technology, is applied in the field of capacitors to achieve the effects of high power factor, easy processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

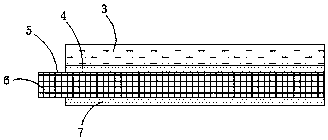

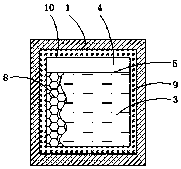

[0026] Such as Figure 1-4 As shown, a novel high-Q capacitor includes a capacitor core 10, a capacitor shell 1 and a tinned copper wire 2. The capacitor core 10 is provided with an insulating layer polypropylene film 6, and both sides of the polypropylene film 6 are By adding a small amount of shielding oil to make the first shielding layer 4 and the second shielding layer 7, the tops of the first shielding layer 4 and the second shielding layer 7 are provided with honeycomb grooves 8, and one side of the polypropylene film 6 is located in the honeycomb shape. The outer side of the groove 8 is coated with a layer of aluminum foil 3 by vacuum evaporation, and one side of the polypropylene film 6 is located on the side of the aluminum foil 3, and a margin 5 is provided; the inner side of the capacitor case 1 is bonded with epoxy glue 9. Capacitor core 10, and epoxy resin glue 9 is evenly filled between the capacitor shell 1 and the capacitor core 10, and one side of the capacit...

Embodiment 2

[0030] A vacuum evaporation processing technology for a novel high-Q capacitor, comprising the following steps: a: Polypropylene film pretreatment: first soak the polypropylene film in deionized water for 0.5-1h, then take it out, lay it flat, Put it in a vacuum dryer for high temperature drying, the drying time is 20-40min, and then perform corona treatment, and open honeycomb grooves on both sides of the polypropylene film;

[0031] b: Evaporation: first place the polypropylene film in a cleaned vacuum chamber, and heat the polypropylene film under vacuum to desorb the gas attached to the surface, then discharge it out of the vacuum chamber to improve the purity of the evaporation, and then Take a small amount of special oil and evenly spread it on the honeycomb grooves on both sides of the polypropylene film, and use it as a shielding layer, then heat and melt the aluminum foil by electron beams, and evenly coat the melted aluminum foil on the polypropylene film The special...

Embodiment 3

[0035] A vacuum evaporation process for a new high-Q capacitor, comprising the following steps: a: Polypropylene film pretreatment: first soak the polypropylene film in deionized water for 0.5-1h, then take it out, lay it flat, Put it in a vacuum dryer for high temperature drying, the drying time is 20-40min, and then perform corona treatment, and open honeycomb grooves on both sides of the polypropylene film;

[0036] b: Evaporation: first place the polypropylene film in a cleaned vacuum chamber, and heat the polypropylene film under vacuum to desorb the gas attached to the surface, then discharge it out of the vacuum chamber to improve the purity of the evaporation, and then Aluminum and zinc are melted by electron beam heating, and the molten aluminum and zinc are evenly plated on the special oil surface outside the honeycomb groove on the polypropylene film, and the surface is made smooth, and the evaporation method adopts impure The method of high square resistance of alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com