Composite additive for enhancing self-repairing property of cement-based material and preparation method thereof

A technology of composite additives and reinforced cement, which is applied in the field of admixtures and can solve the problems of reduced service life, fatigue damage, small cracks, and impact on durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

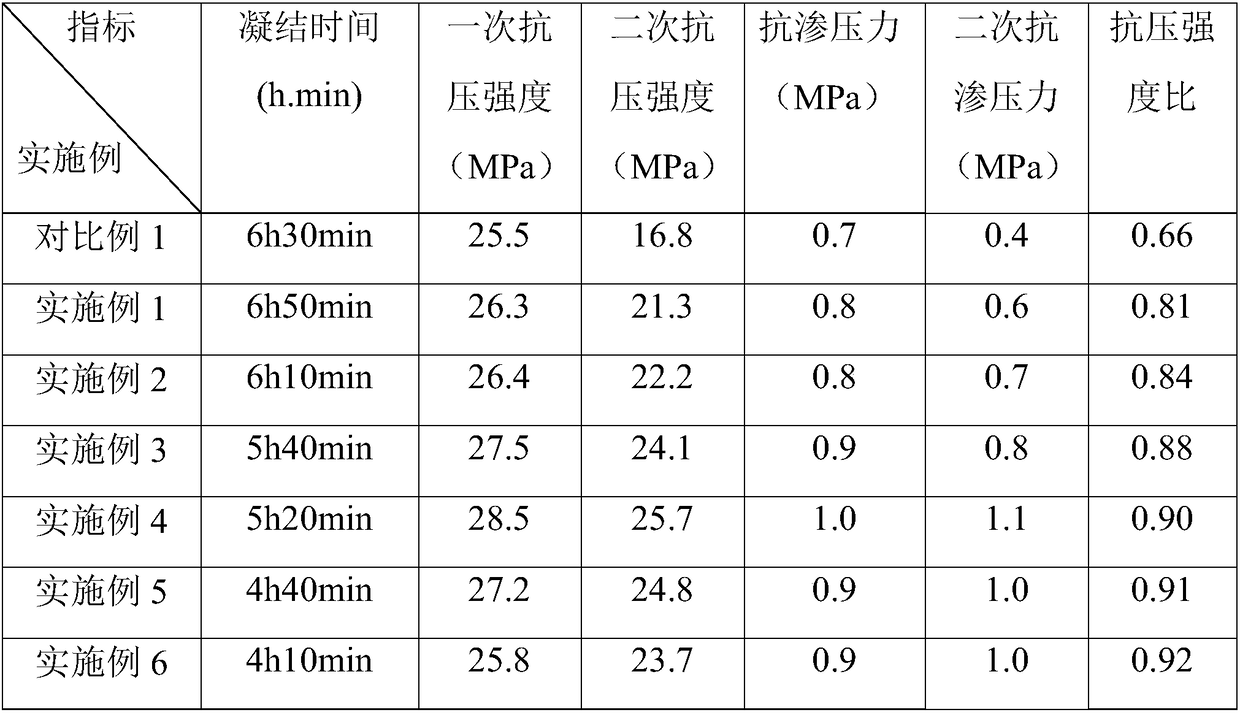

Embodiment 1~6

[0030] The cement-based mortar materials in Examples 1 to 6 are all prepared from the following raw materials at room temperature: 300g of P.O42.5 ordinary Portland cement, 1370g of continuous graded river sand below 4.75mm, 300g of S95 grade mineral powder, 30g of composite additives to enhance the self-healing performance of cement-based materials, and the amount of water added is 300g;

Embodiment 1

[0032] The composite additive of strengthening cement-based material self-healing performance in embodiment 1 comprises the following components by weight percentage: free calcium oxide powder 5%, calcium stearate 10%, calcium oxide powder 74%, fumaric acid 10% , Lithium silicate powder 1%.

Embodiment 2

[0033] The composite additive of strengthening cement-based material self-healing performance in embodiment 2 comprises the following components by weight percentage: free calcium oxide powder 6%, calcium stearate 12%, calcium oxide powder 67%, fumaric acid 12% , Lithium silicate powder 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com