Preparation method of SiC aerogel/ceramic coating structure integrated heat prevention and insulation composite material

A technology of ceramic coating and composite material is applied in the field of preparation of SiC aerogel/ceramic coating structure integrated anti-thermal insulation composite material, which can solve the problems of poor oxidation resistance, small block size, application obstacles, etc. Achieve high mechanical properties and high temperature resistance, improve material properties, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

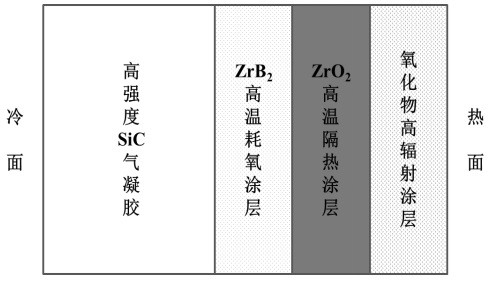

[0042] (1) Preparation of SiC airgel: Dissolve polycarbosilane and vinyl compound in an organic solvent to prepare a uniformly dispersed silicon carbide precursor solution with a concentration of 30wt%; add 0.8 wt% Karstedt catalyst catalyzes hydrosilylation reaction for 8 hours to obtain silicon carbide precursor gel; supercritically dry the silicon carbide precursor gel to obtain silicon carbide precursor aerogel; The precursor airgel is subjected to high-temperature heat treatment to obtain silicon carbide airgel. The heat treatment temperature is 1600°C and the holding time is 3h.

[0043] (2) ZrB 2 Preparation of high-temperature oxygen-consuming coating: ZrB 2 , SiC is mixed evenly according to the mass ratio of 2:1; the mixed powder and silica sol are mixed and stirred according to the mass ratio of 2:3 until the solid and liquid are uniform, and the coating slurry is obtained; the obtained coating slurry is sprayed with a spray gun After drying naturally on the surfa...

Embodiment 2

[0049] (1) Preparation of SiC airgel: Dissolve polycarbosilane and vinyl compound in an organic solvent to prepare a uniformly dispersed silicon carbide precursor solution with a concentration of 20wt%; add 0.8 wt% Karstedt catalyst catalyzes hydrosilylation reaction for 8 hours to obtain silicon carbide precursor gel; supercritically dry the silicon carbide precursor gel to obtain silicon carbide precursor aerogel; The precursor airgel is subjected to high-temperature heat treatment to obtain silicon carbide airgel. The heat treatment temperature is 1600°C and the holding time is 3h.

[0050] (2) ZrB 2 High temperature oxygen consumption coating, ZrO 2 The preparation of the high-temperature heat-shielding coating and the oxide high-radiation coating is the same as in Example 1.

[0051] High-strength SiC airgel with a thickness of 30mm, ZrB 2 High temperature oxygen consumption coating thickness is 100um, ZrO 2 High-temperature thermal insulation coating is 100um, and ox...

Embodiment 3

[0054] (1) Preparation of SiC airgel: Dissolve polycarbosilane and vinyl compound in an organic solvent to prepare a uniformly dispersed silicon carbide precursor solution with a concentration of 15wt%; add 0.8 wt% Karstedt catalyst catalyzes hydrosilylation reaction for 8 hours to obtain silicon carbide precursor gel; supercritically dry the silicon carbide precursor gel to obtain silicon carbide precursor aerogel; The precursor airgel is subjected to high-temperature heat treatment to obtain silicon carbide airgel. The heat treatment temperature is 1600°C and the holding time is 3h.

[0055] (2) ZrB 2 High temperature oxygen consumption coating, ZrO 2 The preparation of the high-temperature heat-shielding coating and the oxide high-radiation coating is the same as in Example 1.

[0056] High-strength SiC airgel with a thickness of 30mm, ZrB 2 High temperature oxygen consumption coating thickness is 100um, ZrO 2 High-temperature thermal insulation coating is 100um, and ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com