High-conductivity polymer solid electrolyte and preparation method thereof

A solid electrolyte and polymer technology, applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of low conductivity and lithium ion migration number, poor compatibility of electrode materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

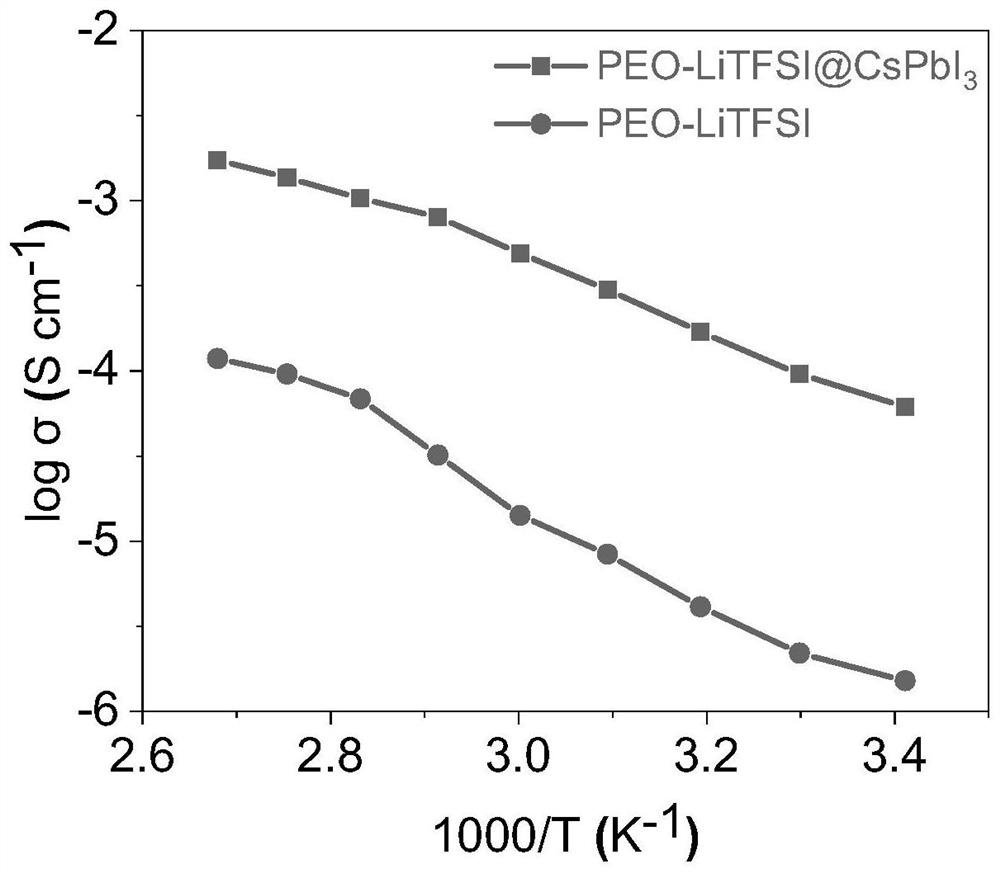

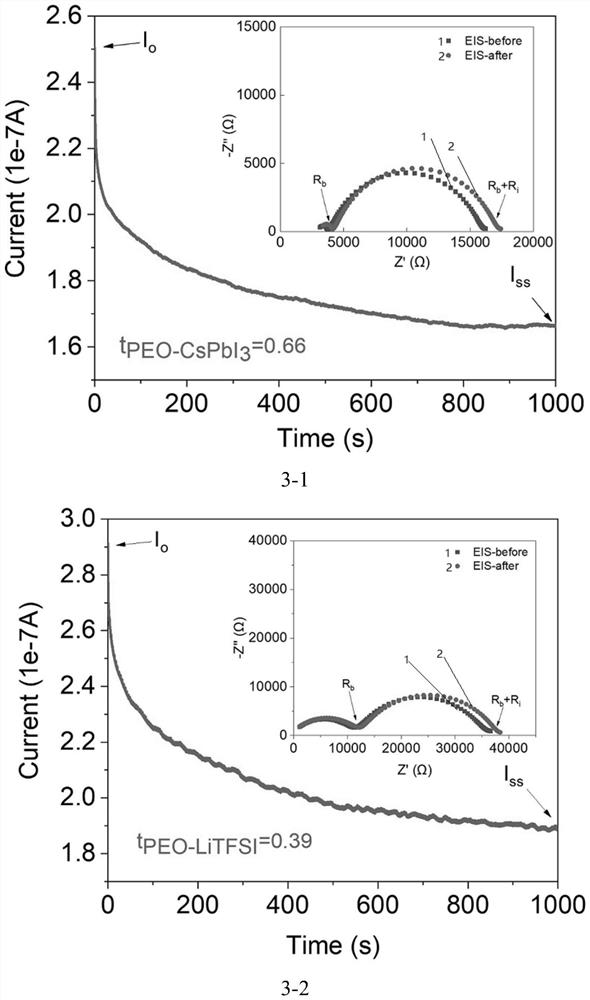

[0038] A preparation method of a highly conductive polymer solid electrolyte, comprising the following steps:

[0039] (1) Preparation of cesium oleate precursor

[0040] 0.391g of cesium carbonate (Cs 2 CO 3 ), 1.27 mL of oleic acid (OA) and 18.73 mL of 1-octadecene (ODE) were added to a 50 mL three-necked flask. The cesium oleate precursor was prepared by stirring at 120°C under argon flow for 60 minutes and heating to 160°C to obtain a clear solution. Because cesium oleate is easily precipitated from ODE at room temperature, it must be preheated to above 80 °C before injection, that is, the cesium oleate precursor should be kept at a temperature above 80 °C for use.

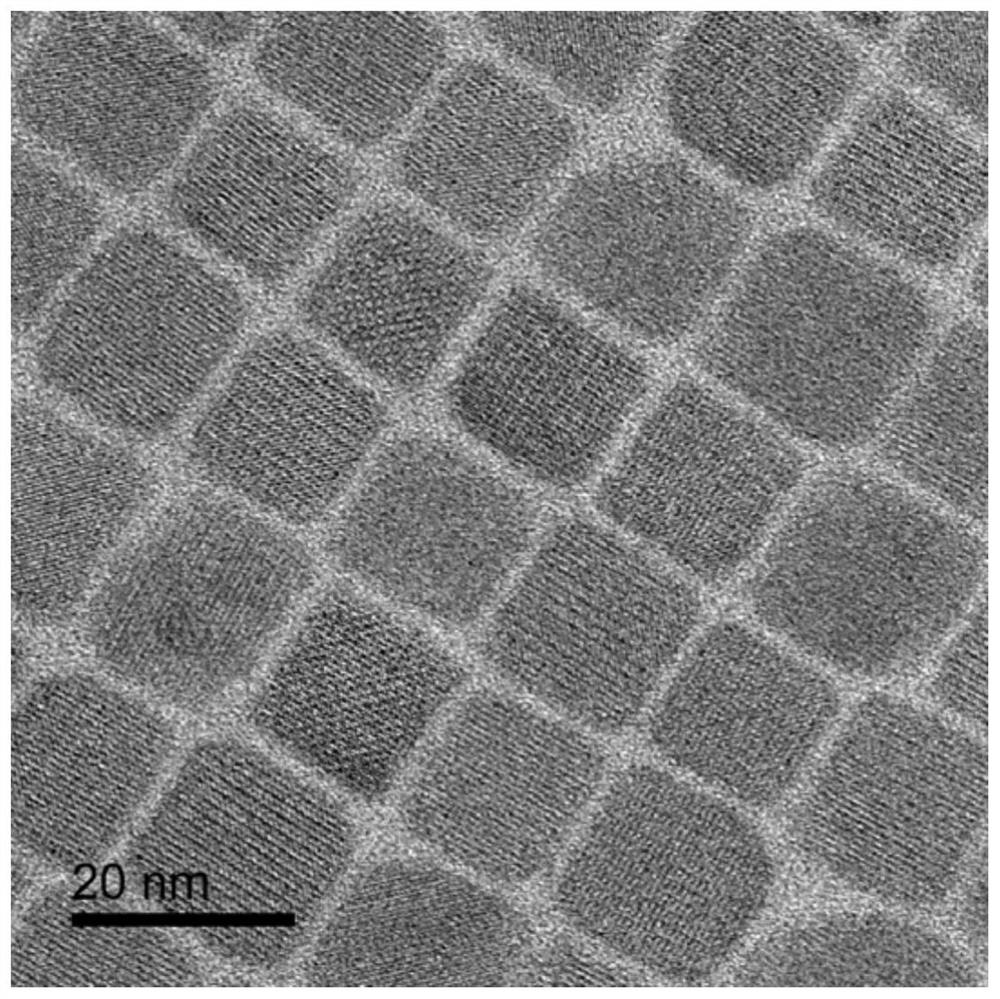

[0041] (2) CsPbI 3 Preparation of perovskite quantum dots

[0042]Add 0.1844g lead iodide PbI to a 100mL three-necked flask 2 , and then 24 mL of 1-octadecene (ODE) was added. After stirring under argon at room temperature for 30 minutes, the mixture was heated to 120°C and stirred for an additional 30 ...

Embodiment 2

[0047] The difference between embodiment 2 and embodiment 1 is that the lead source added is lead chloride, and the addition amount is 0.1112g, and the rest are the same as those in embodiment 1.

Embodiment 3

[0049] The difference between Example 3 and Example 1 is that the lead source added is lead bromide, and the amount added is 0.149 g, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com