Micro-nano mineral grain lubricating additive with self-repairing function, lubricating oil and production method

A technology of lubricating additives and mineral particles, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of unstable actual effect, complex and uncertain serpentine composition, achieve good self-healing function, enhance interface phase Capacitive, good anti-wear and anti-friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

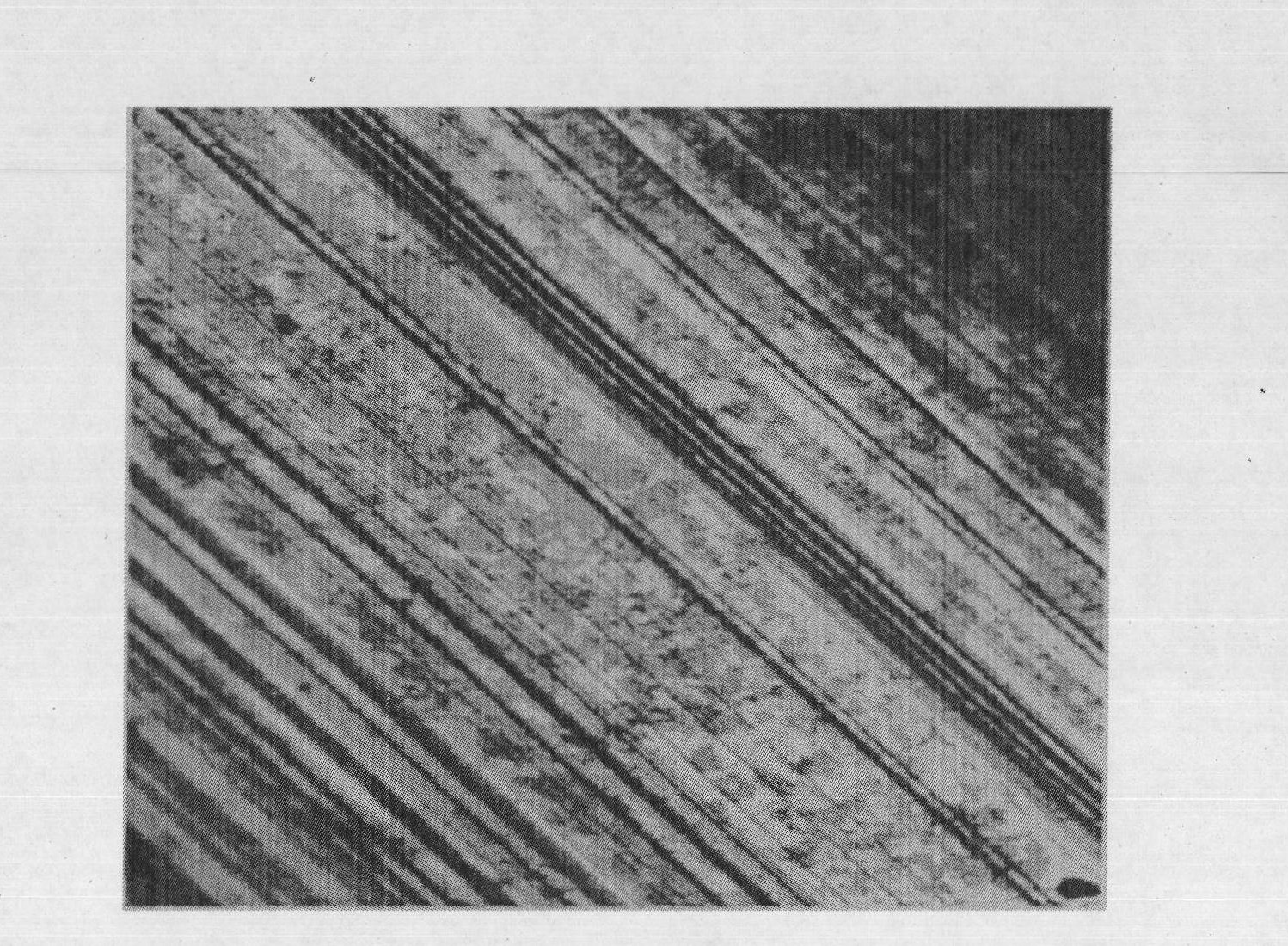

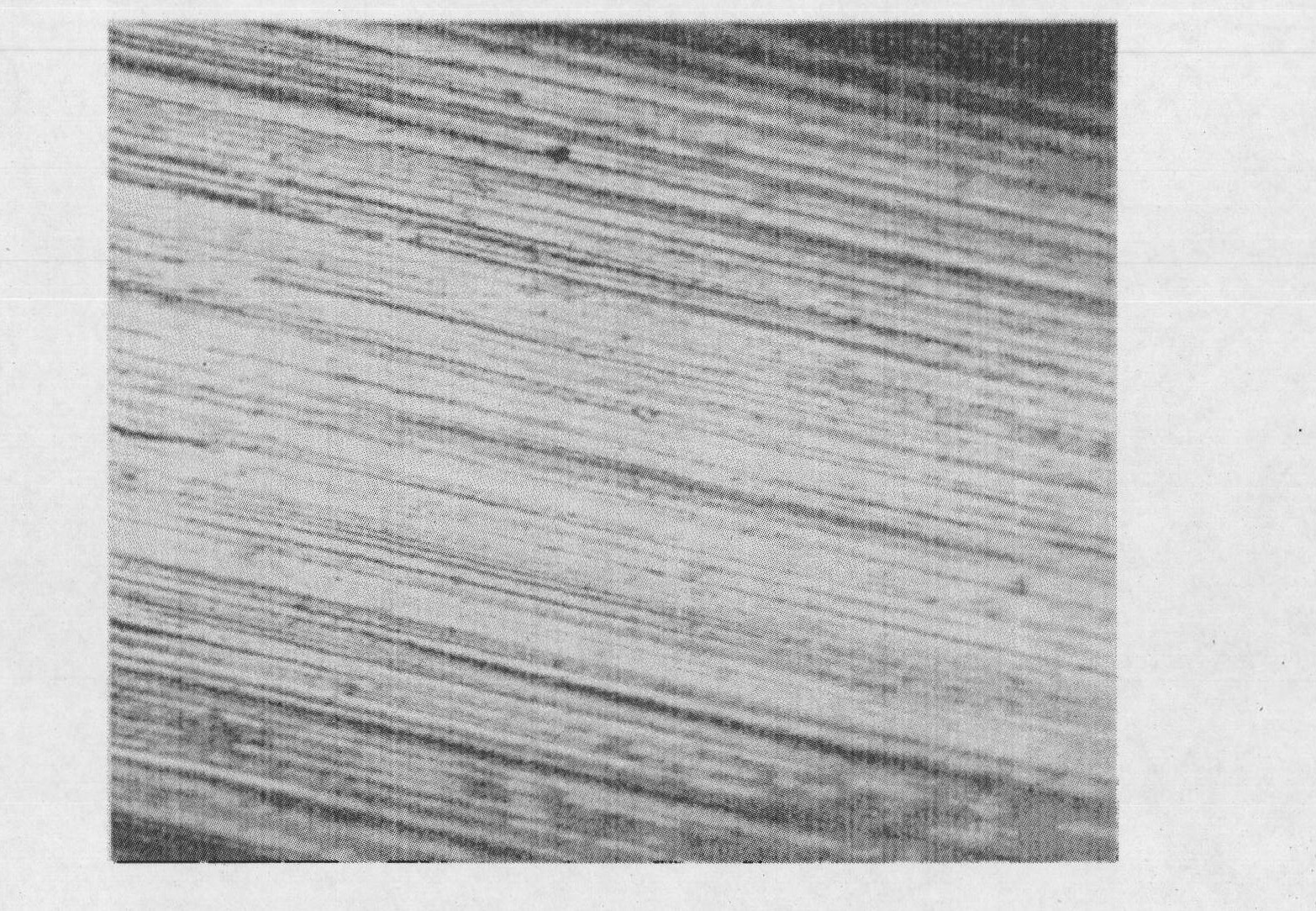

Image

Examples

Embodiment 1

[0022] 1) Preparation of nano MgO powder:

[0023] Take 9.4gMgCl 2 ·6H 2 0. 35ml of ethylene glycol and a small amount of polyvinylpyrrolidone (PVP) are added in a 100mL beaker, and the stirrer is heated with a magnetic heater to fully stir, so that it forms a polymer solution. Slowly add concentrated NH 3 ·H 2 O, producing a milky white colloid, continue to stir for 10 minutes to make it fully react. The slurry was left for 5h, centrifuged and washed with absolute ethanol, dried at 80°C, and calcined in a muffle furnace at 450°C for 3h to obtain off-white powder. The prepared MgO powder was analyzed by a scanning electron microscope, and the average particle size of MgO was calculated to be 50nm according to the particle size statistics of the electron microscope photos. The shape of the particles is spherical.

[0024] 2) Surface modification:

[0025] Take 1g of MgO powder calcined at 450°C for 3 hours in a beaker, take 95% ethanol solution containing 1.0% oleic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com