Porous concrete waterproofing agent and preparation method thereof

A technology of porous concrete and waterproofing agent, applied in the field of concrete, can solve the problems of poor waterproof durability, high repair cost, poor practicability, etc., and achieve the effect of improving waterproof performance and dense gel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

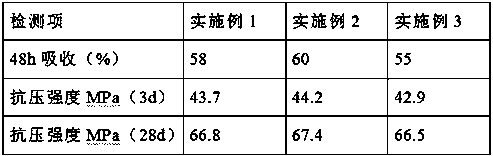

Examples

Embodiment 1

[0049] S1: Prepare materials;

[0050] Weigh oxidizing agent, crosslinking agent, photoinitiator, 3,4-dihydroxyphenylacetic acid, N-hydroxysuccinimide, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide in proportion Amine hydrochloride, sodium alginate and propyne, spare;

[0051] Weigh 2,2'-(1,2-ethylenediyldioxo)diethanethiol, chitosan, hydroxyl-terminated polydimethylsiloxane, dibutyltin dilaurate, ethyl orthosilicate Esters, emulsifiers, liquid paraffin and vanillin, set aside;

[0052] Weigh absolute ethanol, cetyltrimethylammonium bromide, ammonia water and silane coupling agent in proportion, and set aside; take calcium magnesium carbonate, sodium sulfate and sodium silicate, mix and stir for 10 minutes, and obtain a waterproofing aid;

[0053] S2: Preparation of modified silica microspheres:

[0054] Take absolute ethanol and deionized water, stir evenly, then add cetyltrimethylammonium bromide and ammonia water, continue to stir for 10 minutes, slowly add tetraethyl or...

Embodiment 2

[0068] S1: Prepare materials;

[0069] Weigh oxidizing agent, crosslinking agent, photoinitiator, 3,4-dihydroxyphenylacetic acid, N-hydroxysuccinimide, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide in proportion Amine hydrochloride, sodium alginate and propyne, spare;

[0070] Weigh 2,2'-(1,2-ethylenediyldioxo)diethanethiol, chitosan, hydroxyl-terminated polydimethylsiloxane, dibutyltin dilaurate, ethyl orthosilicate Esters, emulsifiers, liquid paraffin and vanillin, set aside;

[0071] Weigh absolute ethanol, cetyltrimethylammonium bromide, ammonia water and silane coupling agent in proportion, and set aside; take calcium magnesium carbonate, sodium sulfate and sodium silicate, mix and stir for 15 minutes, and obtain a waterproof additive;

[0072] S2: Preparation of modified silica microspheres:

[0073] Take absolute ethanol and deionized water, stir evenly, then add cetyltrimethylammonium bromide and ammonia water, continue to stir for 15 minutes, slowly add tetraethyl ...

Embodiment 3

[0087] S1: Prepare materials;

[0088] Weigh oxidizing agent, crosslinking agent, photoinitiator, 3,4-dihydroxyphenylacetic acid, N-hydroxysuccinimide, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide in proportion Amine hydrochloride, sodium alginate and propyne, spare;

[0089] Weigh 2,2'-(1,2-ethylenediyldioxo)diethanethiol, chitosan, hydroxyl-terminated polydimethylsiloxane, dibutyltin dilaurate, ethyl orthosilicate Esters, emulsifiers, liquid paraffin and vanillin, set aside;

[0090] Weigh absolute ethanol, cetyltrimethylammonium bromide, ammonia water and silane coupling agent in proportion, and set aside; take calcium magnesium carbonate, sodium sulfate and sodium silicate, mix and stir for 20 minutes, and obtain a waterproof additive;

[0091] S2: Preparation of modified silica microspheres:

[0092] Take absolute ethanol and deionized water, stir evenly, then add cetyltrimethylammonium bromide and ammonia water, continue to stir for 20 minutes, slowly add tetraethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com